This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 174317 Cable is a specialized component designed for use in commercial trucks. It plays a significant role in the electrical system of these vehicles, facilitating the connection between various components and ensuring the proper functioning of critical systems. Understanding the purpose and operation of this cable is important for maintaining the efficiency and reliability of commercial trucks.

Basic Concepts Related to Cables

Cables in automotive applications are used to transmit electrical power and signals between different parts of a vehicle. They are essential for the operation of numerous systems, including the engine, lighting, and electronic control units. Cables are typically made from conductive materials, such as copper, and are insulated to protect against electrical shorts and environmental factors. Their function within a vehicle’s systems is to provide a reliable pathway for electricity, enabling the operation of various components and ensuring the vehicle functions as intended 1.

Purpose of the 174317 Cable

The Cummins 174317 Cable plays a specific role in the operation of a truck by connecting critical electrical components. It is designed to link the battery to the starter motor, ensuring that the engine can be started reliably. Additionally, it may connect other electrical systems, such as the alternator or various sensors, contributing to the overall electrical integrity of the truck. The cable’s role is to provide a robust and durable connection that can withstand the rigors of commercial truck operation 2.

Key Features

The primary characteristics of the 174317 Cable include its material composition, length, and flexibility. The cable is typically made from high-quality copper to ensure excellent conductivity and durability. It is designed to be sufficiently long to reach between the battery and the starter motor, with additional length to accommodate routing within the truck’s chassis. The cable’s flexibility allows it to be routed through tight spaces without kinking or breaking, ensuring a reliable connection. Unique design elements, such as reinforced insulation and protective coatings, enhance its performance and longevity 3.

Benefits

The Cummins 174317 Cable offers several advantages, including durability, resistance to wear, and environmental factors. Its high-quality construction ensures it can withstand the vibrations and harsh conditions typical of commercial truck operation. The cable’s resistance to corrosion and abrasion helps maintain a reliable electrical connection, contributing to the overall efficiency and reliability of the truck. By ensuring a stable and consistent electrical supply, the cable plays a role in preventing issues related to poor connections, such as starting difficulties or electrical malfunctions 4.

Installation Considerations

Proper installation of the 174317 Cable is important to ensure optimal performance and longevity. Preparatory steps include ensuring the cable routing path is clear of obstructions and that all connection points are clean and free from corrosion. The tools required for installation may include wire cutters, crimping tools, and electrical tape. Best practices involve securing the cable with cable ties to prevent chafing and ensuring all connections are tight and corrosion-free. Following these guidelines helps maintain the integrity of the electrical system and ensures the cable functions as intended 5.

Troubleshooting and Maintenance

Identifying common issues related to the 174317 Cable, such as fraying, corrosion, or loose connections, is important for maintaining the truck’s electrical system. Regular inspections should be conducted to check for signs of wear or damage. Recommended maintenance practices include cleaning connection points to prevent corrosion, replacing frayed sections of the cable, and ensuring all connections remain tight. These practices help prevent electrical issues and ensure the cable remains in good working condition, contributing to the truck’s overall reliability 6.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the commercial truck industry. Known for its wide range of products, including engines, filtration systems, and aftermarket parts, Cummins has built a reputation for quality and reliability. The company’s commitment to innovation and customer satisfaction is reflected in its products, such as the 174317 Cable, which are designed to meet the demanding requirements of commercial truck operation. Cummins’ expertise and dedication to excellence ensure that their components, including cables, contribute to the efficient and reliable performance of commercial trucks 7.

Cummins Cable Part 174317 in NH/NT 855 Engines

The Cummins Cable part 174317 is a critical component in the NH/NT 855 engine series. This cable is designed to ensure seamless communication and control between various engine systems. It is integral to the engine’s operation, providing reliable data transfer and control signals.

In the NH/NT 855 engines, the cable part 174317 interfaces with several key systems, ensuring that the engine operates efficiently and reliably. It connects to the engine control module (ECM), allowing for real-time monitoring and adjustments to engine performance parameters. This cable is essential for maintaining optimal engine performance and ensuring that all systems function in harmony.

The part 174317 is engineered to withstand the harsh conditions within the engine compartment, including high temperatures and vibrations. Its robust construction ensures longevity and reliability, making it a trusted component in the NH/NT 855 engines. This cable is a testament to Cummins’ commitment to quality and durability, providing a dependable solution for engine control and communication 8.

Role of Part 174317 Cable in Engine Systems

Part 174317, a Cablefits component, is integral to the operation of several key engine systems. Its primary function is to facilitate the transmission of mechanical force or signals between various engine components, ensuring seamless and reliable performance.

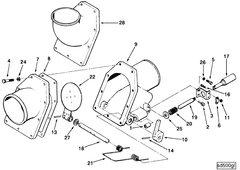

Interaction with the Flexible Shaft

The flexible shaft is a vital component in many engine systems, allowing for the transfer of rotational force in applications where rigid shafts are impractical. Part 174317 Cable plays a significant role here by providing a durable and flexible connection that can withstand the dynamic movements and vibrations inherent in engine operation. This ensures that the rotational force is efficiently transmitted without compromising the integrity of the system.

Contribution to the Overspeed Stop Mechanism

In engine systems, the overspeed stop is a safety feature designed to prevent the engine from exceeding its maximum safe operating speed. Part 174317 Cable is employed to link the overspeed stop mechanism to the engine’s control systems. This connection allows for precise monitoring and adjustment of engine speed, enhancing safety and preventing potential damage from over-revving.

Integration with the Shut Off Assembly Mounting

The shut off assembly is another essential component, responsible for stopping the engine when necessary. Part 174317 Cable is used to connect the shut off assembly to the engine’s control systems, enabling quick and reliable engine shutdowns when required. This integration ensures that the engine can be safely and efficiently stopped in emergency situations or during routine maintenance procedures.

Conclusion

In summary, Part 174317 Cable is a versatile and reliable component that enhances the functionality and safety of engine systems by facilitating critical connections between the flexible shaft, overspeed stop, and shut off assembly mounting. Its robust construction and design ensure it can withstand the harsh conditions of commercial truck operation, contributing to the overall efficiency and reliability of the vehicle.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL9 CM2150 SN, Bulletin Number 4022191.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL9 CM2150 SN, Bulletin Number 4022191.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL9 CM2150 SN, Bulletin Number 4022191.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISL9 CM2150 SN, Bulletin Number 4022191.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.