This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

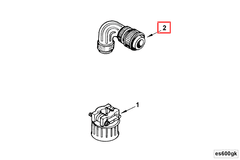

The Cummins 215982 Cable Connector is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate the secure and efficient transfer of power and data within the truck’s electrical system. This connector plays a significant role in ensuring the reliable operation of various electrical components and systems in commercial trucks.

Basic Concepts of Cable Connectors

Cable connectors are devices used to join electrical circuits, allowing for the transfer of power and data between different components within an electrical system. They are essential for maintaining the integrity and functionality of electrical connections, ensuring that power and data are transmitted efficiently and without interruption. In the context of commercial trucks, cable connectors enable the operation of critical systems such as lighting, communication devices, and engine controls 3.

Purpose of the 215982 Cable Connector

The Cummins 215982 Cable Connector is specifically designed to play a role in the electrical system of a truck by providing a reliable connection point for various cables and wires. It ensures that electrical signals and power are transmitted efficiently between different components, contributing to the overall functionality and performance of the truck’s electrical system 4.

Key Features

The Cummins 215982 Cable Connector features a robust design that includes high-quality materials to ensure durability and reliability. Its construction allows for secure connections, minimizing the risk of disconnection or failure. Additionally, the connector is designed to withstand the harsh environmental conditions often encountered in commercial truck operations, enhancing its performance and longevity 2.

Benefits

The Cummins 215982 Cable Connector offers several benefits, including improved reliability and durability in the truck’s electrical system. Its design ensures efficient power and data transfer, contributing to the overall performance and efficiency of the truck. The connector’s robust construction also helps to reduce maintenance requirements and downtime, making it a valuable component for commercial truck operators 4.

Installation Process

Installing the Cummins 215982 Cable Connector involves several steps to ensure a secure and efficient connection. The process includes preparing the connection point, aligning the connector with the cables, and securing it in place using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure proper installation and to avoid damaging the connector or the electrical system 1.

Common Issues and Troubleshooting

Common issues with the Cummins 215982 Cable Connector may include loose connections, corrosion, or damage to the connector. Troubleshooting steps may involve inspecting the connection for signs of wear or damage, cleaning the connector and cables, and ensuring that the connection is secure. In some cases, replacing the connector may be necessary to resolve the issue 4.

Maintenance Tips

Regular maintenance of the Cummins 215982 Cable Connector is important to ensure its longevity and optimal performance. This includes inspecting the connector for signs of wear or damage, cleaning it to remove any corrosion or debris, and ensuring that the connection remains secure. Following the manufacturer’s maintenance guidelines can help to prevent issues and ensure the reliable operation of the truck’s electrical system 1.

Safety Considerations

When working with the Cummins 215982 Cable Connector, it is important to follow safety guidelines to prevent accidents and ensure proper handling. This includes wearing appropriate personal protective equipment, ensuring that the electrical system is de-energized before working on the connector, and following the manufacturer’s instructions for installation and maintenance. Adhering to these safety considerations can help to protect both the technician and the equipment 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a reputation for quality and reliability, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications 1.

Role of Part 215982 Cable Connector in Engine Systems

The part 215982 Cable Connector is an essential component in ensuring the seamless operation of various engine systems. Its primary function is to facilitate secure and reliable connections between different electrical and mechanical components.

Electrical Systems

In electrical systems, the 215982 Cable Connector is utilized to link sensors, control units, and other electronic components. This ensures that signals and power are transmitted efficiently, allowing for precise monitoring and control of engine parameters. The connector’s robust design helps maintain signal integrity, reducing the risk of malfunctions due to loose or corroded connections 3.

Fuel Systems

Within fuel systems, the 215982 Cable Connector plays a significant role in connecting the fuel pump to its control unit. This connection is vital for regulating fuel delivery to the engine, ensuring optimal performance and fuel efficiency. The connector’s durability is particularly important in this application, as it must withstand the harsh environment of fuel systems, including exposure to fuel and varying temperatures 4.

Governor Systems

The 215982 Cable Connector is also integral to governor systems, such as the Woodward 2301 Governor. It connects the governor to the engine’s control mechanisms, allowing for precise adjustments to engine speed and load. This ensures that the engine operates within safe parameters, enhancing overall reliability and performance. The connector’s ability to provide a secure and consistent connection is key to the governor’s effective function 2.

Accessories and Couplings

In accessories and couplings, the 215982 Cable Connector is used to link various auxiliary components to the engine’s primary systems. This includes connections to cooling systems, lubrication systems, and other peripheral devices. The connector’s versatility allows it to adapt to different applications, ensuring that all components work in harmony 3.

Fuel Pump and Governor Integration

When integrating the fuel pump and governor, the 215982 Cable Connector ensures that these critical components communicate effectively. This integration is essential for maintaining engine stability under varying loads and conditions. The connector’s reliable performance helps prevent issues such as fuel starvation or over-speeding, which could lead to engine damage 4.

Conclusion

The Cummins 215982 Cable Connector is a versatile and dependable component that enhances the functionality and reliability of engine systems across various applications. Its role in ensuring secure and efficient connections between components is fundamental to the overall performance and longevity of the engine.

References

-

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388669.

↩ ↩ ↩ ↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ ↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ ↩ ↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.