This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3164185 Bench Calibration Cable is a specialized tool designed for the maintenance and calibration of heavy-duty truck engines. This cable facilitates precise adjustments and measurements in a controlled environment, ensuring that engines operate at optimal efficiency and performance. Its role in the calibration process is significant, as it contributes to the overall reliability and longevity of truck engines 1.

Purpose and Functionality

The Cummins 3164185 Bench Calibration Cable is integral to the calibration process of truck engines. It allows for accurate measurements and adjustments to be made in a bench setting, away from the complexities of the vehicle’s environment. This controlled calibration ensures that engine components are fine-tuned to manufacturer specifications, enhancing performance and fuel efficiency. The cable interfaces with calibration equipment and the engine’s electronic control unit (ECU), enabling technicians to make precise adjustments to engine parameters 2.

Key Features

The Cummins 3164185 Bench Calibration Cable is characterized by its robust design and high-quality materials. It is engineered to withstand the rigors of frequent use in professional settings. The cable features durable connectors that ensure a secure and reliable connection between the calibration equipment and the engine’s ECU. Its design allows for easy handling and manipulation, facilitating a smooth calibration process 3.

Benefits of Using the 3164185 Bench Calibration Cable

Utilizing the Cummins 3164185 Bench Calibration Cable offers several advantages. It enhances the accuracy of engine calibration, leading to improved engine performance and efficiency. The cable’s ease of use reduces the time required for calibration procedures, potentially leading to cost savings for fleet operators. Additionally, its durability ensures a long service life, providing value over time 4.

Installation and Setup

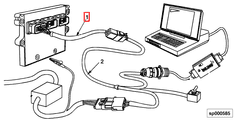

Proper installation and setup of the Cummins 3164185 Bench Calibration Cable involve connecting it to both the calibration equipment and the engine’s ECU. It is important to follow manufacturer guidelines for connection and setup to ensure accurate calibration. Best practices include verifying all connections are secure and using the cable in a clean, dry environment to prevent damage from contaminants 5.

Troubleshooting Common Issues

Common issues with the Cummins 3164185 Bench Calibration Cable may include connection problems or signal interference. To address these, ensure all connections are secure and free from corrosion. If signal interference is suspected, relocating the calibration equipment away from potential sources of electromagnetic interference may resolve the issue. Regular inspection and maintenance of the cable can prevent many common problems 6.

Maintenance and Care

Regular maintenance and care of the Cummins 3164185 Bench Calibration Cable are vital for its longevity and consistent performance. This includes cleaning the cable and connectors after each use to remove any dirt or debris, storing it in a dry place to prevent moisture damage, and inspecting it for signs of wear or damage before each use. Proper care ensures the cable remains in optimal condition for accurate calibrations 7.

Compatibility and Usage

The Cummins 3164185 Bench Calibration Cable is designed for use with specific Cummins engine models and calibration systems. It is important to verify compatibility with the specific engine and calibration equipment being used to ensure proper function and accurate calibration results 8.

Safety Considerations

When using the Cummins 3164185 Bench Calibration Cable, it is crucial to observe safety protocols and precautions. This includes wearing appropriate personal protective equipment (PPE) to protect against electrical hazards and ensuring the work area is free from flammable materials. Following these safety guidelines helps protect both the technician and the equipment during the calibration process 9.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications 10.

Role of Part 3164185 Bench Calibration Cable in Engine Systems

The Part 3164185 Bench Calibration Cable is an essential component in the maintenance and calibration of engine systems, particularly when integrated with a Hardware Certification Kit (HCK). This cable facilitates precise measurements and adjustments necessary for ensuring the engine operates within specified parameters.

Integration with Hardware Certification Kit

When used in conjunction with the HCK, the Bench Calibration Cable allows for the accurate testing and certification of engine hardware. The HCK typically includes a suite of tools and software designed to verify that all engine components meet the required standards. The calibration cable serves as the physical link between the engine’s electronic control unit (ECU) and the testing equipment, enabling data transfer and real-time monitoring.

Calibration Process

During the calibration process, the Bench Calibration Cable connects the ECU to a calibration bench, which is equipped with various sensors and diagnostic tools. This setup allows engineers and mechanics to:

- Measure Voltage and Current: Ensure that the electrical systems within the engine are functioning correctly.

- Adjust Fuel Injection Timing: Fine-tune the fuel injection system to optimize performance and efficiency.

- Verify Sensor Accuracy: Check the accuracy of various sensors, such as the oxygen sensor and mass airflow sensor, to ensure they provide reliable data to the ECU.

- Test Actuators: Evaluate the performance of actuators, such as the throttle body and variable valve timing system, to confirm they respond appropriately to ECU commands.

Data Logging and Analysis

The calibration cable also plays a significant role in data logging. By connecting the ECU to a data acquisition system, engineers can record performance metrics under different operating conditions. This data is invaluable for:

- Identifying Anomalies: Detecting any irregularities in engine performance that may indicate underlying issues.

- Optimizing Performance: Making data-driven adjustments to improve engine efficiency and power output.

- Ensuring Compliance: Verifying that the engine meets all regulatory and manufacturer specifications.

Maintenance and Troubleshooting

In addition to calibration, the Bench Calibration Cable is useful for maintenance and troubleshooting. It allows mechanics to:

- Diagnose Faults: Identify electrical or mechanical faults within the engine system by analyzing data transmitted through the cable.

- Perform Firmware Updates: Update the ECU firmware to the latest version, ensuring the engine benefits from the latest improvements and bug fixes.

- Conduct Pre-Delivery Inspections: Ensure that newly manufactured engines are functioning correctly before they are delivered to customers.

Conclusion

The Cummins 3164185 Bench Calibration Cable is a versatile and indispensable tool in the arsenal of any engineer or mechanic working with engine systems. Its role in calibration, data logging, and maintenance ensures that engines operate efficiently, reliably, and within specified parameters.

-

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISB5.9 CM2880 B110. Bulletin Number 4332884.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISB5.9 CM2880 B110. Bulletin Number 4332884.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.