This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

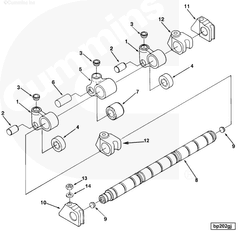

The Cummins 3161477 Cam Follower Lever is a vital component in heavy-duty truck engines, contributing to efficient and reliable engine performance. This part works in conjunction with other engine components to ensure smooth and consistent engine function.

Basic Concepts of Cam Follower Levers

A cam follower lever is a mechanical device that converts rotational motion into linear motion by interacting with a cam. In an engine, the cam follower lever is part of the valve train system, following the cam’s contour to transfer motion to the valves. This ensures that the valves open and close at precise intervals, which is essential for the engine’s combustion process 1.

Purpose of the 3161477 Cam Follower Lever

The 3161477 Cam Follower Lever is designed to interact with the camshaft in a truck engine, translating the rotational motion of the camshaft into linear motion to actuate the valves. This ensures that the valves open and close in sync with the engine’s operation, contributing to overall engine performance. The lever works with other components such as the camshaft, pushrods, and rocker arms to maintain precise timing and lift 2.

Key Features

The 3161477 Cam Follower Lever is constructed from high-quality materials to withstand the demanding conditions within a heavy-duty truck engine. Its design includes a robust body, precise machining for smooth operation, and a durable surface finish to resist wear. These features enhance the lever’s performance and longevity, ensuring reliable operation under various engine loads and speeds.

Benefits

The 3161477 Cam Follower Lever offers several advantages, including improved engine efficiency through accurate valve timing and lift. Its durable construction enhances the engine’s reliability, reducing the likelihood of premature failure. The precise engineering of the lever supports consistent engine performance, which is crucial for heavy-duty truck applications 3.

Installation and Integration

Installing the 3161477 Cam Follower Lever requires careful attention to ensure proper integration into the engine. The process involves removing the old lever, inspecting the camshaft and valve train components for wear, and positioning the new lever. Special tools may be required to properly seat the lever and ensure it operates within specified tolerances. Following the manufacturer’s guidelines for installation is crucial to maintain engine performance and longevity.

Common Issues and Troubleshooting

Typical problems associated with the 3161477 Cam Follower Lever may include wear, noise, or improper valve operation. Diagnostic methods involve inspecting the lever for signs of wear or damage, checking the valve train components for proper clearance and operation, and listening for any abnormal noises during engine operation. Potential solutions may range from adjusting the valve clearance to replacing worn components to maintain optimal performance.

Maintenance Tips

Regular maintenance practices are essential to ensure the longevity and effectiveness of the 3161477 Cam Follower Lever. This includes periodic inspection of the lever and related components for signs of wear or damage, ensuring proper lubrication, and following the manufacturer’s recommended service intervals. Adhering to these maintenance procedures helps prevent issues and supports the reliable operation of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the heavy-duty truck industry for producing high-quality, reliable, and efficient engines. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and durability.

Cam Follower Lever (Part 3161477) in Cummins Engines

The Cam Follower Lever, identified by the part number 3161477, is a critical component in several Cummins engine models. This part is integral to the engine’s operation, ensuring smooth and reliable performance across various engine configurations.

L10 CELECT and L10 GAS Engines

In the L10 CELECT and L10 GAS engines, the Cam Follower Lever plays a pivotal role in the valve train mechanism. It interacts directly with the camshaft to control the opening and closing of the engine’s valves. This interaction is crucial for maintaining the engine’s timing and ensuring that the valves operate in sync with the pistons. The precision of the Cam Follower Lever is essential for the efficient combustion process, which directly impacts the engine’s power output and fuel efficiency.

L10 MECHANICAL Engine

Similarly, in the L10 MECHANICAL engine, the Cam Follower Lever is a key component in the valve train system. Its function is to translate the rotational motion of the camshaft into the linear motion required to open and close the engine valves. This lever ensures that the valves operate at the correct timing, which is vital for the engine’s overall performance and longevity. The durability and precision of the Cam Follower Lever are critical in maintaining the engine’s efficiency and reliability.

Grouping of Engines

The Cam Follower Lever (Part 3161477) is compatible with the L10 CELECT, L10 GAS, and L10 MECHANICAL engines. These engines share a common design philosophy and operational requirements, making the Cam Follower Lever a versatile component across these models. The commonality in design allows for easier maintenance and repair, as the same part can be used across different engine types, simplifying the supply chain and reducing inventory costs for service providers.

Understanding the Integration of Part 3161477 Cam Follower Lever in Engine Systems

The 3161477 Cam Follower Lever is an integral component in the orchestration of engine operations, specifically within the valve train mechanism. This lever interfaces directly with the cam, translating the rotational motion of the camshaft into linear motion to actuate the valves.

When the camshaft rotates, driven by the crankshaft via timing belt or chain, the lobes on the cam push against the Cam Follower Lever. This action causes the lever to pivot, which in turn opens the valve by pulling or pushing on the valve stem through the rocker arm or directly, depending on the engine design.

The efficiency and precision of this motion are paramount for the engine’s performance. The Cam Follower Lever must maintain a consistent and smooth contact with the cam to ensure that the valves open and close at the correct times and with the appropriate force. This synchronization is essential for optimal combustion efficiency, power output, and fuel economy.

In overhead cam (OHC) engines, the Cam Follower Lever might be part of a direct-acting system where it directly contacts the valve, or it could be part of an indirect system involving rocker arms or pushrods in overhead valve (OHV) engines. In either configuration, the role of the Cam Follower Lever is to reliably transmit the cam’s motion to the valve, ensuring that the engine’s valves operate in harmony with the pistons’ movements.

Furthermore, the design and material of the Cam Follower Lever are tailored to withstand the high stresses and temperatures within the engine compartment. It must be durable enough to resist wear from constant contact with the cam and flexible enough to absorb any shocks or irregularities in the cam’s surface.

Conclusion

The 3161477 Cam Follower Lever is a key player in the valve train, ensuring that the valves open and close in precise coordination with the engine’s operation, thereby contributing to the engine’s overall efficiency and performance. Regular maintenance and proper installation are crucial to ensure the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.