3164090

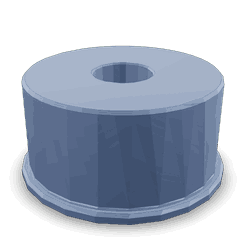

Camshaft Bore Centering Guide

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3164090 Camshaft Bore Centering Guide is a specialized component designed to facilitate the precise alignment of the camshaft within the engine block during assembly or maintenance procedures. Its role is significant in ensuring the proper functioning and longevity of heavy-duty truck engines.

Basic Concepts

Camshaft bore centering guides are integral to the engine assembly process. They ensure that the camshaft is correctly positioned within the engine block, which is vital for the synchronized operation of the engine’s valves. Proper camshaft alignment is essential for the efficient operation of the engine, as it directly affects valve timing and, consequently, engine performance and durability 1.

Purpose and Function

The 3164090 Camshaft Bore Centering Guide is designed to ensure accurate camshaft placement. By centering the camshaft within the bore, it helps maintain the correct valve timing and clearances. This precise alignment contributes to the engine’s overall performance, reliability, and efficiency, reducing the risk of mechanical issues that could arise from improper camshaft positioning 2.

Key Features

The 3164090 Camshaft Bore Centering Guide is characterized by its robust design and the quality materials used in its construction. These features ensure durability and effectiveness in facilitating accurate camshaft alignment. Its design is tailored to fit specific engine models, enhancing its functionality and ease of use during engine assembly or maintenance.

Benefits

Utilizing the 3164090 Camshaft Bore Centering Guide offers several advantages. It contributes to improved engine efficiency by ensuring precise camshaft alignment, which is crucial for optimal valve operation. Additionally, it helps reduce wear on engine components by maintaining correct valve clearances, leading to enhanced overall engine performance and longevity 3.

Installation Process

Installing the 3164090 Camshaft Bore Centering Guide requires following a step-by-step procedure to ensure optimal results. It is important to adhere to manufacturer guidelines during installation to guarantee the guide’s effectiveness in centering the camshaft. Proper installation is key to achieving the desired engine performance and reliability.

Troubleshooting and Maintenance

Identifying common issues related to camshaft alignment and the use of centering guides is important for maintaining engine performance. Routine maintenance of the 3164090 Camshaft Bore Centering Guide, including checking for wear or damage, ensures its continued effectiveness in facilitating accurate camshaft placement.

Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly renowned for its diesel engines and components. With a rich history and a diverse product range, Cummins has established a reputation for quality and reliability in the production of engine parts, including the 3164090 Camshaft Bore Centering Guide.

Role of Part 3164090 Camshaft Bore Centering Guide in Engine Systems

The 3164090 Camshaft Bore Centering Guide is an essential component in ensuring the precise alignment and installation of camshafts within the engine block. When used in conjunction with a camshaft bushing replacer kit, this guide significantly enhances the efficiency and accuracy of the camshaft replacement process.

Integration with Camshaft Bushing Replacer Kit

When replacing camshaft bushings, the camshaft bore centering guide plays a pivotal role. It ensures that the new bushings are installed concentrically within the engine block’s bores. This alignment is vital for the smooth operation of the camshaft, which in turn affects valve timing and overall engine performance. The guide helps in maintaining the correct spacing and orientation, reducing the risk of misalignment that could lead to increased wear or failure of the camshaft and associated components.

Enhanced Installation Process

The use of the camshaft bore centering guide in tandem with the bushing replacer kit streamlines the installation process. Mechanics and engineers can achieve a higher degree of accuracy, which is particularly important in high-performance engines where even minor deviations can impact engine efficiency and longevity. The guide assists in holding the camshaft in place while the new bushings are pressed into the bores, ensuring that they seat properly without any undue stress on the camshaft or surrounding components.

Improved Engine Reliability

By ensuring that the camshaft is correctly aligned and the bushings are properly installed, the camshaft bore centering guide contributes to the overall reliability of the engine. Proper alignment prevents excessive friction and wear on the camshaft and its bearings, leading to a more durable and efficient engine operation. This is especially beneficial in engines that undergo frequent high-stress conditions, such as those in racing or high-performance applications.

Facilitating Maintenance and Repairs

In maintenance and repair scenarios, the camshaft bore centering guide simplifies the reinstallation of the camshaft after servicing. It ensures that the camshaft is positioned accurately within the engine block, which is essential for maintaining the engine’s performance standards post-repair. This component is particularly useful in scenarios where the camshaft needs to be removed and reinstalled multiple times, as it consistently provides the necessary alignment for each installation.

Conclusion

The Cummins 3164090 Camshaft Bore Centering Guide plays a crucial role in the precise alignment of camshafts within engine blocks, enhancing engine performance, reliability, and efficiency. Its integration with camshaft bushing replacer kits further streamlines the installation process, contributing to the overall durability and efficiency of the engine.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023.

↩ -

Automotive Principles: Diagnosis and Service, James D. Halderman, Prentice Hall, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.