This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

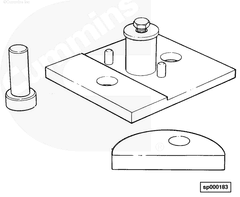

The 3376966 Cam Follower Rebuild Fixture by Cummins is a specialized tool designed for the maintenance and repair of heavy-duty truck engines. This fixture is integral to the process of rebuilding cam followers, which are components in the valve train system of an engine. By providing a precise and efficient method for rebuilding these components, the fixture contributes to the overall reliability and performance of truck engines.

Basic Concepts of Cam Follower Rebuild Fixture

Cam follower systems are fundamental to the operation of an engine’s valve train, allowing for the precise opening and closing of engine valves in synchronization with the camshaft. The necessity of rebuild fixtures in maintaining these components arises from the need to ensure that cam followers are accurately and consistently rebuilt. This is important for maintaining the engine’s performance and longevity. The 3376966 Cam Follower Rebuild Fixture addresses this need by providing a dedicated platform for the precise rebuilding of cam followers.

Purpose and Functionality

The 3376966 fixture plays a significant role in the operation and maintenance of truck engines by facilitating the precise rebuilding of cam followers. This fixture allows for the accurate alignment and adjustment of cam followers, ensuring that they meet the required specifications for optimal engine performance. By aiding in the rebuilding process, the fixture helps maintain the integrity of the valve train system, contributing to the engine’s overall efficiency and reliability.

Key Features

The primary features of the 3376966 fixture include its robust design, which is engineered to withstand the rigors of heavy-duty truck engine maintenance. The fixture is constructed from high-quality materials to ensure durability and precision. Unique attributes of the fixture include its adjustable components, which allow for customization based on the specific requirements of different cam follower models. This versatility enhances the fixture’s effectiveness in a wide range of applications.

Benefits of Using the 3376966 Cam Follower Rebuild Fixture

Utilizing the 3376966 fixture offers several advantages, including improved accuracy in the rebuild process, which leads to more reliable engine performance. The fixture also contributes to time efficiency by streamlining the rebuilding process, allowing for quicker turnaround times in engine maintenance. Additionally, the use of this fixture can result in potential cost savings for fleet operators by reducing the need for engine replacements and minimizing downtime 1.

Installation and Setup

Proper installation and setup of the 3376966 fixture are crucial for ensuring optimal performance and safety. The installation process involves securing the fixture to a stable work surface and verifying that all components are correctly aligned. Setup includes adjusting the fixture to accommodate the specific cam follower being rebuilt, ensuring that all measurements and alignments are precise. Following the manufacturer’s guidelines for installation and setup is recommended to achieve the best results.

Operational Guidelines

Correct usage of the 3376966 fixture includes adhering to safety precautions and operational best practices. This involves ensuring that the work area is clean and free from obstructions, wearing appropriate personal protective equipment, and following the step-by-step instructions provided by Cummins for operating the fixture. Regular inspection of the fixture for wear or damage is also advised to maintain its effectiveness and safety 2.

Troubleshooting and Maintenance

Common issues that may arise with the 3376966 fixture include misalignment of components or wear on adjustable parts. Troubleshooting steps may involve re-aligning components or replacing worn parts to ensure the fixture continues to operate effectively. Maintenance tips include regular cleaning of the fixture to remove debris and lubricants, as well as periodic inspection for any signs of damage or wear. Adhering to these maintenance practices will help ensure the longevity and consistent performance of the fixture.

Compatibility and Applications

The 3376966 fixture is designed to work with a variety of engines and cam follower systems, highlighting its versatility and applicability across different truck models. Its compatibility ensures that fleet operators and maintenance professionals can rely on this fixture for a wide range of engine maintenance tasks, making it a valuable tool in the heavy-duty truck industry.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its commitment to quality and innovation in engine components and repair tools. With a history of developing reliable and efficient engine solutions, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of engine components and repair tools designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to quality is evident in its rigorous testing and quality control processes, ensuring that its products, including the 3376966 fixture, deliver reliable performance and durability 3.

Conclusion

The 3376966 Cam Follower Rebuild Fixture by Cummins is a valuable tool for the maintenance and repair of heavy-duty truck engines. Its robust design, precise functionality, and compatibility with a wide range of engines make it an essential component in the toolkit of any professional working in the heavy-duty truck industry. By ensuring the accurate rebuilding of cam followers, this fixture contributes to the overall efficiency, reliability, and longevity of truck engines.

-

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007.

↩ -

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022.

↩ -

Advances in Engine and Powertrain Research and Technology, Tigran Parikyan Ed, Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.