This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

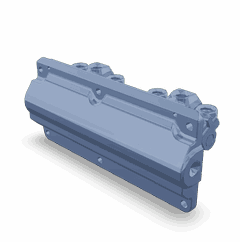

Introduction to Cam Follower Housing

Cam follower housing is a critical component in the operation of internal combustion engines, especially in commercial trucks. This part is integral to the engine’s valve train system, ensuring smooth and reliable operation. For engineers, mechanics, and fleet operators, understanding the function and importance of cam follower housing is essential for maintaining engine performance and longevity 1.

The Role of Cummins 3411412 Cam Follower Housing

The Cummins 3411412 Cam Follower Housing is specifically engineered for use in Cummins engines. It houses the cam followers, which translate the rotational motion of the camshaft into linear motion, actuating the engine’s valves. This ensures that the valves open and close at precise times, which is crucial for the engine’s performance, efficiency, and durability 2.

How Cummins 3411412 Cam Follower Housing Works

The cam follower housing is typically constructed from high-strength cast iron or aluminum, offering durability and resistance to wear. Inside the housing, the cam followers ride on the camshaft lobe, which is contoured to match the desired valve timing profile. As the camshaft rotates, the cam followers move up and down, pushing on tappets that, in turn, open and close the valves 3.

Importance in Truck Engines

In commercial truck engines, the cam follower housing must endure high stresses and temperatures. The Cummins 3411412 Cam Follower Housing is designed to meet these demands, ensuring reliable operation under heavy-duty conditions. Proper functioning of this part is vital for maintaining engine performance, reducing wear, and preventing costly breakdowns.

Troubleshooting Cummins 3411412 Cam Follower Housing

Regular maintenance and timely troubleshooting can help prevent issues with the cam follower housing. Here are some common problems and their solutions:

-

Unusual Noises: Knocking or tapping noises can indicate worn cam followers or loose tappets. Inspect the cam followers and tappets for wear and replace if necessary.

-

Valve Train Issues: If the engine experiences valve train issues, such as valve float or sticking valves, inspect the cam follower housing for damage or misalignment. Ensure all components are properly lubricated and in good condition.

-

Oil Leaks: Oil leaks around the cam follower housing can be a sign of worn seals or gaskets. Replace any damaged seals and ensure proper tightening of fasteners.

Maintenance Tips for Cummins 3411412 Cam Follower Housing

To ensure the longevity and reliability of the Cummins 3411412 Cam Follower Housing, follow these maintenance tips:

-

Regular Inspections: Conduct regular visual inspections of the cam follower housing for signs of wear, cracks, or leaks. Pay attention to the condition of the cam followers and tappets.

-

Lubrication: Ensure that the cam follower housing and its components are properly lubricated. Use the recommended oil and follow the manufacturer’s guidelines for oil changes and maintenance intervals.

-

Cleanliness: Keep the cam follower housing clean and free of debris. Contaminants can cause wear and reduce the effectiveness of the lubrication.

-

Proper Installation: When replacing the cam follower housing, ensure it is properly installed and all fasteners are tightened to the correct specifications. Misalignment can lead to premature wear and failure.

About Cummins

Cummins is a global power leader and a pioneer in the design and manufacture of engines, engine-related technology, and related parts. With a strong focus on innovation and quality, Cummins provides reliable and efficient solutions for the commercial truck industry. Their parts, including the Cummins 3411412 Cam Follower Housing, are engineered to meet the demanding requirements of heavy-duty applications.

Cummins Cam Follower Housing (Part 3411412) Compatibility

The Cummins Cam Follower Housing (Part 3411412) is a critical component that fits seamlessly with several of Cummins’ engine models. This part is designed to ensure the smooth operation of the camshaft by providing a stable housing for the cam followers. Here are the Cummins engines that are compatible with this part:

N14 Engines

- N14 CELECT PLUS

- N14 MECHANICAL

Both the N14 CELECT PLUS and N14 MECHANICAL engines rely on the Cam Follower Housing to maintain the integrity of the camshaft mechanism. This housing is essential for the proper alignment and operation of the cam followers, which in turn affects the engine’s overall performance and longevity.

QSN14 Engines

- QSN14 CM876 N103

- QSNT14 CM876 N102

The QSN14 CM876 N103 and QSNT14 CM876 N102 engines also utilize the Cam Follower Housing (Part 3411412). These engines, which are part of the QSN14 series, benefit from the precise engineering of this component to ensure reliable camshaft operation. The housing’s design allows for minimal wear and tear, contributing to the engine’s durability and efficiency.

By ensuring that the Cam Follower Housing is correctly installed and maintained, operators can expect consistent engine performance and reduced downtime. This part is a testament to Cummins’ commitment to quality and reliability in their engine components.

Role of Part 3411412 Cam Follower Housing in Engine Systems

The 3411412 Cam Follower Housing is an integral component in the orchestration of various engine systems, ensuring seamless operation and efficiency. This housing encases the cam follower, which is essential for translating the rotational motion of the camshaft into linear motion for the valve train.

Interaction with the Block

The Cam Follower Housing is securely mounted onto the engine block. The block, being the structural backbone of the engine, provides the necessary rigidity and stability for the housing. This mounting ensures that the housing remains in precise alignment with the camshaft and cylinder, facilitating accurate valve timing and operation.

Coordination with the Cylinder

Positioned adjacent to the cylinder, the Cam Follower Housing plays a key role in the valve operation process. As the camshaft rotates, the follower housed within the 3411412 interacts with the cam lobes. This interaction is transmitted through the housing to the valve mechanism associated with the cylinder, controlling the intake and exhaust processes vital for combustion.

Relationship with the Follower

The follower itself is a pivotal element within the Cam Follower Housing. It directly contacts the camshaft lobes, absorbing the motion and transferring it to the valve train. The housing protects the follower from wear and external contaminants, ensuring longevity and consistent performance.

Synergy with the Cam

The camshaft, with its precisely machined lobes, dictates the timing and duration of valve events. The Cam Follower Housing, by housing the follower, ensures that this motion is accurately conveyed. The housing’s design allows for minimal friction and wear, preserving the integrity of the cam’s profile and the follower’s surface.

Conclusion

In summary, the 3411412 Cam Follower Housing is a linchpin in the engine’s valve train system, facilitating the transfer of motion from the camshaft to the valves through the follower, all while being supported by the engine block and working in concert with the cylinder. By understanding and properly maintaining this critical component, engineers, mechanics, and fleet operators can ensure the reliable operation of their commercial truck engines.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.