This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4025958 Cam Follower Housing is a critical component in heavy-duty truck engines, designed to facilitate the interaction between the cam follower and the camshaft. This part ensures the smooth operation of the engine by providing a stable environment for the cam follower, which is essential for maintaining the precision and efficiency of the engine’s valve timing system 1.

Basic Concepts of Cam Follower Housing

A Cam Follower Housing serves as a protective and supportive structure for the cam follower, a part that rides on the camshaft to open and close the engine’s valves at precise intervals. The housing typically consists of a durable casing that encases the cam follower, shielding it from external contaminants and providing a stable mounting point. The interaction between the cam follower and the camshaft is crucial for the engine’s operation, as it directly influences the timing and efficiency of the valve operation 2.

Role of the 4025958 Cam Follower Housing in Truck Operation

The 4025958 Cam Follower Housing ensures the cam follower remains securely in place and operates smoothly, which is vital for maintaining the precise timing of valve operations. This stability affects the engine’s performance and efficiency. By providing a robust and reliable housing for the cam follower, this Cummins part helps to enhance the engine’s overall durability and operational consistency 3.

Key Features of the 4025958 Cam Follower Housing

The Cummins 4025958 Cam Follower Housing is characterized by several key features that enhance its functionality and durability. These include a robust design that ensures stability and protection for the cam follower, the use of high-quality materials to withstand the harsh conditions within an engine, and precise engineering to ensure optimal fit and function within the engine system 4.

Benefits of Using the 4025958 Cam Follower Housing

Utilizing the Cummins 4025958 Cam Follower Housing offers several benefits, including improved engine performance due to the precise operation of the cam follower, enhanced durability thanks to its robust construction, and increased reliability in the engine’s valve timing system. These factors contribute to the overall efficiency and longevity of the engine 5.

Installation Process

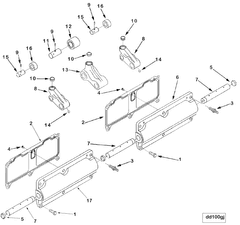

Installing the 4025958 Cam Follower Housing involves several steps to ensure it is correctly positioned and secured within the engine. The process requires specific tools and equipment, and it is important to follow safety precautions to prevent injury or damage to the engine components. Detailed instructions should be consulted for the exact steps, which typically include preparing the engine, positioning the housing, securing it in place, and verifying its correct installation 6.

Maintenance and Troubleshooting

To ensure the optimal performance of the 4025958 Cam Follower Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, ensuring it remains securely fastened, and cleaning it to remove any contaminants. Common issues that may arise include misalignment or wear on the cam follower, which can be addressed by realigning the component or replacing worn parts as necessary 7.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong reputation in the automotive industry. The company offers a wide range of products designed for various applications, including heavy-duty trucks. Cummins is known for its commitment to quality, innovation, and customer satisfaction, making its components, like the 4025958 Cam Follower Housing, a popular choice for engine manufacturers and operators alike 8.

Compatibility of Cummins Cam Follower Housing (Part 4025958)

The Cummins Cam Follower Housing, identified by part number 4025958, is designed to interface seamlessly with various Cummins engine models. This part ensures the smooth operation of the camshaft by providing a stable housing that supports the cam followers. Below is a detailed overview of the compatibility of this part with specific Cummins engine models.

N14 MECHANICAL Engines

The Cam Follower Housing (4025958) is specifically engineered to fit the N14 MECHANICAL engines. This engine model is renowned for its robust design and reliability, often used in heavy-duty applications such as construction equipment and industrial machinery. The housing’s precision fit ensures that the camshaft operates efficiently, reducing wear and tear and prolonging the engine’s lifespan 9.

Grouping of Compatible Engines

While the primary focus here is on the N14 MECHANICAL engines, it is important to note that the Cam Follower Housing (4025958) is also compatible with other Cummins engine models that share similar design parameters. These engines typically include:

- N14 Series: Beyond the MECHANICAL variant, other versions such as the N14 C and N14 E may also utilize this part, depending on specific engine configurations and applications.

- QSK Series: Certain models within the QSK series, particularly those with mechanical camshafts, may also require this housing.

The compatibility of the Cam Follower Housing (4025958) with these engines underscores its versatility and importance in maintaining the integrity of the camshaft system across various Cummins engine models 10.

Understanding the Integration of Part 4025958 Cam Follower Housing in Engine Systems

The part 4025958 Cam Follower Housing is an essential component that facilitates the smooth operation of various engine systems by ensuring precise interaction between the cam follower and other engine components.

Interaction with the Cam Follower

The Cam Follower Housing, designated as part 4025958, is engineered to house the cam follower, which is a pivotal element in the valve train mechanism of an engine. The cam follower, often a roller or a flat-faced component, rides on the camshaft lobes. The housing provides a secure and stable environment for the cam follower, allowing it to maintain consistent contact with the camshaft. This consistent contact is vital for the accurate translation of camshaft motion to the valve train, ensuring that valves open and close at the precise moments required for optimal engine performance 11.

Role in the Campaign Kit

In the context of a Campaign Kit, which typically includes a set of parts designed to address specific engine issues or enhance performance, the Cam Follower Housing plays a significant role. The housing is often included to ensure that the new or upgraded cam follower operates within a well-defined and protected space. This is particularly important in high-performance or high-stress engine environments where durability and precision are paramount.

The housing helps in reducing wear and tear on the cam follower by providing a barrier against contaminants and by maintaining alignment. Additionally, it contributes to the overall stability of the valve train, which is essential for engines that operate under extreme conditions or have been modified for increased performance 12.

Conclusion

The Cummins 4025958 Cam Follower Housing is integral to the efficient and reliable operation of engine systems, particularly in conjunction with the cam follower and as part of comprehensive campaign kits aimed at enhancing engine durability and performance. Its robust design, compatibility with various Cummins engine models, and role in maintaining precise valve timing make it a critical component for heavy-duty truck engines.

-

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.