This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

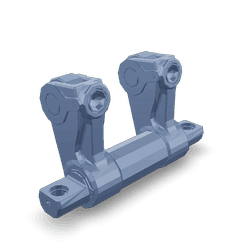

The Cummins Cam Follower Lever, part number 4065753, is a critical component in the operation of commercial truck engines. Cummins, a leader in the automotive industry, is renowned for its commitment to quality and innovation. This part is designed to enhance the efficiency and reliability of truck engines, playing a significant role in their overall performance.

Basic Concepts of Cam Follower Levers

A cam follower lever is a mechanical component that interacts with the camshaft in an engine. Its primary function is to translate the rotational motion of the camshaft into linear motion, which is then used to operate the valves. This interaction is essential for the timing and efficiency of the engine’s valve operation. The cam follower lever works in conjunction with other engine components, such as the valve train, to ensure precise and consistent valve actuation 1.

Role of the Cummins Cam Follower Lever in Truck Operation

The Cummins Cam Follower Lever is specifically designed to work within the valve train of a truck engine. It plays a role in the operation by interacting with the camshaft to control the opening and closing of the engine’s valves. This precise control is vital for the engine’s performance, as it ensures that the valves open and close at the correct times in relation to the piston’s movement. The lever’s design allows for efficient transfer of motion from the camshaft to the valves, contributing to the engine’s overall efficiency and power output 2.

Key Features of the Cummins Cam Follower Lever

The Cummins Cam Follower Lever is characterized by its robust design and high-quality construction. It is made from durable materials that can withstand the high stresses and temperatures within a truck engine. The lever’s design includes features that enhance its durability and performance, such as precise machining for smooth operation and materials that resist wear and corrosion. These attributes contribute to the lever’s reliability and longevity in demanding engine environments 3.

Benefits of Using the Cummins Cam Follower Lever

Utilizing the Cummins Cam Follower Lever in a truck engine offers several advantages. It contributes to improved engine performance by ensuring precise valve timing and actuation. The lever’s durable construction and high-quality materials enhance the engine’s reliability and reduce the likelihood of premature wear or failure. Additionally, its efficient design helps to optimize fuel consumption and reduce emissions, making it a valuable component for both performance and environmental considerations 4.

Installation and Integration

Proper installation of the Cummins Cam Follower Lever is crucial for its effective operation within a truck engine. It should be installed according to the manufacturer’s guidelines to ensure it is correctly aligned with the camshaft and valve train. Attention to detail during installation, such as proper torque settings and alignment checks, is important to maintain the lever’s performance and longevity. Integration into the engine system requires careful consideration of the lever’s interaction with other components to ensure smooth and efficient operation 5.

Maintenance and Troubleshooting

Routine maintenance of the Cummins Cam Follower Lever is important to ensure its continued performance and longevity. This includes regular inspections for signs of wear or damage, as well as lubrication according to the manufacturer’s recommendations. Troubleshooting common issues, such as unusual noises or performance drops, may involve checking the lever’s alignment, condition of the camshaft, and overall health of the valve train. Early detection and correction of issues can prevent more significant problems and extend the component’s service life 6.

Common Issues and Solutions

Common problems associated with the Cummins Cam Follower Lever may include wear, misalignment, or damage due to extreme conditions. Solutions to these issues range from realigning or lubricating the lever to replacing worn or damaged components. Regular maintenance and inspections can help identify potential issues before they lead to more serious engine problems. In cases where replacement is necessary, using genuine Cummins parts ensures compatibility and maintains the engine’s performance standards 7.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industries, with a history of innovation and quality. The company is known for its commitment to developing reliable and efficient engine components, including the Cummins Cam Follower Lever. Cummins’ reputation is built on its dedication to engineering excellence, customer satisfaction, and continuous improvement in its product offerings 8.

Cummins Cam Follower Lever 4065753 in Engine Applications

The Cummins Cam Follower Lever 4065753 is a critical component in the operation of various Cummins engine models. This part plays a pivotal role in ensuring the smooth and efficient functioning of the engine’s valve train system. It is designed to interact with the camshaft to maintain proper valve timing and operation, which is essential for the engine’s performance and longevity.

Integration in Cummins Engine Models

The Cam Follower Lever 4065753 is compatible with a range of Cummins engines, including but not limited to:

- QSK19G: This engine model is part of the Cummins QSK series, known for its robust design and high performance in heavy-duty applications. The Cam Follower Lever 4065753 ensures that the camshaft’s motion is accurately transferred to the valve train, maintaining precise valve timing and operation.

Importance in Engine Performance

The proper functioning of the Cam Follower Lever 4065753 is crucial for several reasons:

- Valve Timing: It ensures that the engine’s valves open and close at the correct times, which is vital for efficient combustion and power output.

- Reduced Wear: By maintaining consistent contact with the camshaft, it helps reduce wear and tear on the camshaft and valve train components.

- Engine Reliability: Its role in the valve train system contributes to the overall reliability and durability of the engine.

Installation and Maintenance

When installing the Cam Follower Lever 4065753, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. Regular maintenance checks should be conducted to inspect for any signs of wear or damage, which could affect engine performance. Proper lubrication and alignment are also critical to the longevity and effectiveness of this component.

Conclusion

By understanding the role and importance of the Cummins Cam Follower Lever 4065753, engine operators and maintenance personnel can better appreciate its contribution to the overall efficiency and reliability of Cummins engines. Proper installation, maintenance, and troubleshooting are essential to ensure the continued performance and longevity of this critical component.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Reif, K. (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). QSL9 CM2250, Bulletin Number 2883351, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSL9 CM2250, Bulletin Number 2883351, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSL9 CM2250, Bulletin Number 2883351, Operation and Maintenance Manual.

↩ -

Cummins Inc. (n.d.). QSL9 CM2250, Bulletin Number 2883351, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.