213559

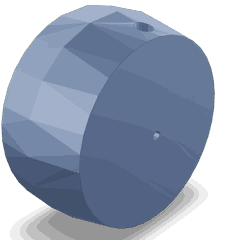

Cam Follower Socket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 213559 Cam Follower Socket, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part is integral to the engine’s operation, ensuring smooth and efficient performance. Cummins, a renowned name in the engine manufacturing industry, produces this component with a focus on durability and reliability, catering to the demanding requirements of commercial trucking 1.

Basic Concepts of Cam Follower Sockets

A Cam Follower Socket is a mechanical component that interacts with the camshaft in an engine. It typically consists of a socket that houses a roller or needle bearing, allowing it to move along the cam’s surface with minimal friction. This interaction is crucial for the operation of the engine’s valve train, as it translates the camshaft’s rotational motion into linear motion for the valves. The design of the Cam Follower Socket enables it to withstand high loads and varying speeds, ensuring consistent valve operation 2.

Role of the 213559 Cam Follower Socket in Truck Operation

The 213559 Cam Follower Socket plays a specific role in the operation of a truck engine. It is positioned to engage with the camshaft, transferring motion to the engine’s valve train. This transfer is vital for the opening and closing of the engine’s valves, which control the intake of air and fuel and the exhaust of combustion gases. The efficiency of this process directly impacts the engine’s performance and fuel efficiency. The 213559 model is engineered to enhance these aspects, contributing to the overall reliability and performance of the truck’s engine 3.

Key Features of the 213559 Cam Follower Socket

The 213559 Cam Follower Socket is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precision-engineered bearings that reduce friction and wear, promoting smooth operation. Additionally, the socket’s design allows for efficient heat dissipation, which is crucial for maintaining optimal operating temperatures within the engine.

Benefits of Using the 213559 Cam Follower Socket

Utilizing the 213559 Cam Follower Socket in a truck engine offers several benefits. Its high-quality construction and design contribute to improved engine performance and efficiency. The reduced friction and wear lead to longer component life, potentially resulting in cost savings over time. Furthermore, the socket’s ability to maintain optimal operating conditions within the engine can lead to better fuel economy and reduced emissions.

Troubleshooting and Maintenance Suggestions

To ensure the longevity and optimal performance of the 213559 Cam Follower Socket, regular maintenance and troubleshooting are recommended. Common issues may include wear on the bearing surfaces or contamination within the socket. Regular inspections can help identify these issues early, allowing for timely repairs or replacements. Additionally, keeping the engine clean and well-lubricated can prevent contamination and reduce wear on the Cam Follower Socket.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its extensive product range, which includes engines, components, and aftermarket parts designed to meet the rigorous demands of commercial applications. Cummins’ dedication to quality and innovation ensures that its products, like the 213559 Cam Follower Socket, are at the forefront of engine component manufacturing.

Compatibility of Cam Follower Socket Part 213559 with Cummins Engines

The Cam Follower Socket part 213559, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral in ensuring the smooth operation of the camshaft and valve train system, providing a stable interface between the camshaft and the valve train components.

G-Series Engines

- G855

- G855 CM558

- GTA38 G CMEICS G116C

- GTA855 CM558 (CM2358) G101

K-Series Engines

- K19

- K38

- K50

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

N-Series Engines

- N14 CELECT

- N14 G

- N14 MECHANICAL

NH/NT Series Engines

- NH/NT 855

QSK Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

V-Series Engines

- V28

Role of Part 213559 Cam Follower Socket in Engine Systems

In the intricate orchestration of engine components, the Part 213559 Cam Follower Socket assumes a significant role by ensuring seamless interaction between various elements. This component is integral to the operation of the cam follower and cam follower assembly, facilitating precise motion transfer from the camshaft follower to other engine parts.

The Cam Follower Socket interfaces directly with the cam follower housing and cam follower lever, allowing for efficient load distribution and minimizing wear. It is also a key element in the cam follower (top level assembly) housing, where it supports the dynamic movement of the cam follower against the cam.

In the context of the cylinder block, the Cam Follower Socket works in conjunction with the valve tappet and tappet assembly to maintain valve timing accuracy. This precision is essential for the proper functioning of the injector tappet and floating tappet kit, which rely on consistent cam lobe interaction.

Furthermore, the Cam Follower Socket is vital in the master cam follower housing and master cam follow housing, where it contributes to the stability and durability of the master cam foll. and ebm: follower,cam. Its role extends to the long block assy. - 50, enhancing the overall performance and reliability of the engine.

The integration of the Cam Follower Socket with the actuator and pdc (Powertrain Control Module) ensures that the engine’s electronic control systems receive accurate feedback, allowing for optimal engine management. Additionally, it supports the hsg (Hybrid Synergy Drive) system in hybrid engines, contributing to efficient power delivery.

Conclusion

In summary, the 213559 Cam Follower Socket is a linchpin in the engine’s mechanical and electronic systems, facilitating smooth operation and enhancing the engine’s overall efficiency and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.