This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3018795 U-Bolt is a specialized fastener designed for use in commercial trucks. Its primary function is to secure various components within the truck’s structure, ensuring stability and integrity under operational conditions. This part is integral to maintaining the truck’s performance and safety, particularly in heavy-duty applications where secure fastening is paramount.

Basic Concepts of U-Bolts

A U-Bolt is a type of fastener shaped like the letter “U” with threaded ends. It is commonly used in applications where a bolt needs to wrap around an object, such as a pipe or beam, and be secured with a nut. Mechanically, the U-Bolt operates by applying clamping force when the nuts are tightened, which creates friction between the U-Bolt and the object it is securing. This design allows for a strong and stable connection in various industrial and automotive applications 1.

Purpose of the Cummins 3018795 U-Bolt

The Cummins 3018795 U-Bolt serves a specific role in the operation of commercial trucks. It is utilized in areas where secure fastening is required, such as attaching exhaust components, securing brackets, or mounting various parts to the truck’s frame. Its application is vital for maintaining the structural integrity and performance of the truck, ensuring that components remain firmly in place under dynamic driving conditions.

Key Features

The Cummins 3018795 U-Bolt is distinguished by several key features. It is constructed from high-quality materials, typically steel, which provides excellent durability and resistance to corrosion. The design specifications of this U-Bolt include precise dimensions and a robust build, ensuring it can withstand the rigors of heavy-duty use. Additionally, it may feature unique attributes such as a specific bend radius or surface treatment that enhances its performance and longevity 2.

Benefits

Using the Cummins 3018795 U-Bolt offers several benefits. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The reliable fastening provided by this U-Bolt enhances the overall stability and safety of the truck’s components. Furthermore, its design contributes to improved performance by securely holding parts in place, which is crucial for the efficient operation of commercial trucks.

Installation Process

Proper installation of the Cummins 3018795 U-Bolt involves several steps to ensure a secure fastening. Begin by positioning the U-Bolt around the object it will secure. Use appropriate tools, such as a wrench, to tighten the nuts on each end of the U-Bolt. It is important to follow best practices, such as ensuring even tightening to distribute clamping force uniformly and avoiding over-tightening, which can damage the U-Bolt or the object it is securing 3.

Troubleshooting and Maintenance

Common issues with U-Bolts can include loosening over time due to vibrations or corrosion. Regular maintenance checks are recommended to ensure the U-Bolt remains securely fastened. Signs of wear or failure, such as rust or deformation, should be addressed promptly to prevent component detachment. Proper lubrication and periodic tightening can help prolong the lifespan of the Cummins 3018795 U-Bolt.

Safety Considerations

When using U-Bolts, it is important to consider safety factors such as proper torque specifications to avoid over-tightening, which can lead to damage. Understanding the load-bearing capacities of the U-Bolt is crucial to ensure it can handle the intended application’s stresses. Environmental factors, such as exposure to moisture or chemicals, should also be considered, as they can affect the U-Bolt’s performance and longevity.

Cummins Corporation

Cummins Corporation is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance truck components, Cummins has established a strong reputation for excellence. The company’s dedication to advancing technology and maintaining stringent quality control standards ensures that its products, including the Cummins 3018795 U-Bolt, meet the demanding requirements of commercial truck applications.

Compatibility with Cummins Engines

The U-Bolt part number 3018795 is a versatile component designed to fit a variety of Cummins engines. This part is essential for securing various engine components, ensuring stability and reliability during operation.

K-Series Engines

The U-Bolt part 3018795 is compatible with the K19, K38, and K50 engines. These engines are known for their robust design and are often used in heavy-duty applications. The U-Bolt’s design allows it to securely fasten components such as exhaust manifolds and other critical parts, ensuring they remain firmly in place under high stress conditions.

N-Series Engines

For the N14 MECHANICAL engine, the U-Bolt part 3018795 is a crucial component for maintaining the integrity of the engine’s structure. This engine is widely used in various industries due to its durability and performance. The U-Bolt’s application in this engine ensures that components like the cylinder block and other vital parts are held securely, contributing to the engine’s overall reliability.

QSK Engines

The QSK19 CM500 engine also benefits from the U-Bolt part 3018795. This engine is designed for high-performance applications and requires components that can withstand significant stress. The U-Bolt’s design ensures that it can securely fasten parts such as the turbocharger and exhaust system, maintaining the engine’s structural integrity under demanding conditions.

V-Series Engines

The V28 engine is another application where the U-Bolt part 3018795 is used. This engine is known for its power and efficiency, making it suitable for various industrial applications. The U-Bolt’s role in this engine is to secure components like the cylinder head and other critical parts, ensuring they remain firmly attached and do not shift during operation.

NH/NT Engines

The NH/NT 855 engine also utilizes the U-Bolt part 3018795. This engine is designed for heavy-duty applications and requires components that can endure significant stress. The U-Bolt’s design ensures that it can securely fasten parts such as the exhaust manifold and other critical components, maintaining the engine’s structural integrity under demanding conditions.

Role in Engine Systems

The Cummins 3018795 U-Bolt is an essential component in various engine systems, facilitating secure mounting and alignment of multiple assemblies and panels. Its application spans across several key components, ensuring stability and proper functioning.

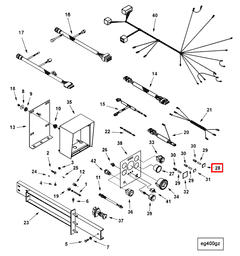

Integration with Control Cabinets

In control cabinets, the U-Bolt is used to mount and secure electrical components and wiring harnesses. This ensures that the components remain firmly in place, reducing the risk of vibrations causing disconnections or damage.

Engine Instruction Top-Level Assembly Panel

For the engine instruction top-level assembly panel, the U-Bolt plays a significant role in attaching the panel to the engine frame. This secure attachment is vital for maintaining the panel’s position and ensuring that all instructional labels and indicators are readily accessible and clearly visible to operators.

Engine Instrument Panel

On the engine instrument panel, the U-Bolt is employed to mount gauges, switches, and other instrumentation. This secure mounting prevents the instruments from shifting during operation, ensuring accurate readings and reliable performance.

Engine Instrument Top-Level Assembly Panel

Similarly, in the engine instrument top-level assembly panel, the U-Bolt ensures that all instruments are mounted securely. This is particularly important for maintaining the integrity of the readings provided by these instruments, which are essential for monitoring engine performance.

Generator Control Panel

In the generator control panel, the U-Bolt is used to attach the panel to the generator frame. This secure attachment is necessary for the stable operation of the control panel, which houses critical components for generator management.

Generator Instrument Panel

For the generator instrument panel, the U-Bolt ensures that all gauges and indicators are mounted securely. This is important for the accurate monitoring of generator performance and for the safety of the system.

Indicator Light

Indicator lights, which provide visual signals for various engine and generator conditions, are often mounted using U-Bolts. This ensures that the lights remain in the correct position and are easily visible to operators.

Instrument Panel

The instrument panel, which may include a variety of gauges and controls, relies on U-Bolts for secure attachment to the engine or generator frame. This ensures that the panel remains stable and that all components function as intended.

Instrument Panel Panel

In cases where multiple instrument panels are used, U-Bolts are essential for mounting these panels securely. This ensures that all instruments are correctly positioned and that the panels remain stable during operation.

General Panel Usage

Across various panels used in engine systems, U-Bolts are a common mounting solution. They provide a robust and reliable method for attaching panels to frames, ensuring that all components remain in place and function correctly.

Conclusion

The Cummins 3018795 U-Bolt is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its durable construction, precise design, and versatile applications make it an essential part for ensuring the stability, safety, and performance of heavy-duty vehicles and engines. Proper installation, regular maintenance, and adherence to safety considerations are vital for maximizing the benefits of this U-Bolt.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.