This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3918367 Filler Cap Assembly is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fuel system, contributing to the overall efficiency and safety of the truck’s operation. Understanding its purpose and significance can help in maintaining the vehicle’s performance and longevity.

Basic Concepts of Filler Cap Assembly

A filler cap assembly is a part of a truck’s fuel system that allows for the safe and secure addition of fuel to the vehicle’s tank. It typically consists of a cap, a gasket or seal, and sometimes a venting system. The assembly functions by providing a barrier that prevents fuel from spilling out while allowing it to be added under pressure from a fuel pump. It also plays a role in maintaining the integrity of the fuel system by preventing contaminants from entering the fuel tank 1.

Purpose of the 3918367 Filler Cap Assembly

The 3918367 Filler Cap Assembly is designed to facilitate the refueling process in commercial trucks. It ensures that fuel is added to the tank in a controlled manner, minimizing the risk of spills and ensuring that the fuel system remains sealed against external contaminants. Additionally, it contributes to the pressure regulation within the fuel tank, which is important for the efficient operation of the truck’s engine 2.

Key Features

The 3918367 Filler Cap Assembly is constructed from durable materials that are resistant to the corrosive effects of fuel. It includes a sealing mechanism that ensures a tight fit on the fuel tank, preventing leaks. The design of the assembly also incorporates features that make it easy to use, such as a simple twist-off cap, and it may include safety features like a venting system to release pressure build-up within the tank.

Benefits

The use of the 3918367 Filler Cap Assembly offers several benefits. It enhances the integrity of the fuel system by providing a secure seal on the fuel tank. It simplifies the refueling process, making it more convenient for operators. Additionally, the assembly includes safety features that help to prevent accidents during refueling, such as pressure release mechanisms that reduce the risk of fuel spills 3.

Installation Process

Installing the 3918367 Filler Cap Assembly requires careful attention to ensure a proper fit. The process involves cleaning the fuel tank opening, aligning the assembly with the tank, and securing it in place. Tools such as a torque wrench may be required to ensure that the assembly is tightened to the manufacturer’s specifications. It is important to follow the installation instructions provided by Cummins to ensure correct fitting and function.

Maintenance Tips

Regular maintenance of the 3918367 Filler Cap Assembly is important for its longevity and performance. This includes checking the seal for wear and replacing it if necessary, ensuring that the cap is securely fastened after each use, and inspecting the assembly for any signs of damage or corrosion. Keeping the area around the cap clean can also help to prevent contaminants from affecting the seal.

Troubleshooting Common Issues

Common issues with filler cap assemblies can include leaks, difficulty in opening or closing the cap, and problems with the venting system. Troubleshooting these issues may involve inspecting the seal for damage, ensuring that the cap is properly aligned and tightened, and checking the venting system for obstructions or malfunctions.

Safety Considerations

When handling and maintaining the 3918367 Filler Cap Assembly, it is important to observe safety practices. This includes wearing appropriate personal protective equipment, ensuring that the truck is parked on a level surface during refueling, and avoiding smoking or open flames near the fuel tank. It is also important to follow the manufacturer’s guidelines for handling and disposing of fuel.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s products are known for their reliability and performance, contributing to the efficiency and safety of commercial vehicles.

Cummins Engine Compatibility with Filler Cap Assembly Part 3918367

The Cummins Filler Cap Assembly part number 3918367 is designed to fit seamlessly with several engine models, ensuring a secure and efficient sealing mechanism. This part is crucial for maintaining the integrity of the engine’s fuel system by preventing contamination and ensuring proper fuel vapor management.

Engine Compatibility

-

4B3.9 and 6B5.9 Engines The Filler Cap Assembly part 3918367 is compatible with both the 4B3.9 and 6B5.9 engines. These engines, known for their robust performance and reliability, benefit from the precise fit and functionality provided by this filler cap assembly. It ensures that the fuel system remains sealed, which is critical for maintaining engine efficiency and longevity.

-

B5.9 G Engine The B5.9 G engine also integrates well with the Filler Cap Assembly part 3918367. This engine, part of the Cummins lineup, is designed for heavy-duty applications, and the filler cap assembly plays a vital role in its operation. The cap’s design ensures that the engine’s fuel system remains protected from external contaminants, which is essential for the engine’s performance in demanding environments.

By ensuring a proper fit and function, the Filler Cap Assembly part 3918367 contributes to the overall reliability and efficiency of these engines, making it a critical component for maintenance and operation.

Role of Part 3918367 Filler Cap Assembly in Engine Systems

The 3918367 filler cap assembly is an essential component in the fueling system of an engine, ensuring the secure and efficient transfer of fuel into the system. It interfaces directly with the fuel tank, typically located beneath the vehicle’s cover, and is designed to prevent fuel spillage and contamination.

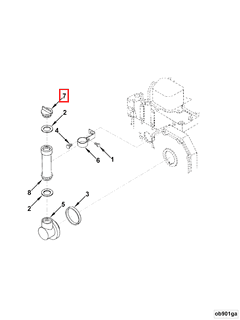

When integrating the 3918367 filler cap assembly with the engine system, it is important to understand its interaction with other components. The assembly is mounted on the fuel tank, which is often situated above the cylinder block. This positioning allows for a straightforward fuel delivery path from the filler cap to the fuel lines that feed the engine.

The filler cap assembly includes a sealing mechanism that creates an airtight connection with the fuel tank. This seal is vital for maintaining fuel pressure within the tank, which is necessary for the proper operation of fuel injection systems commonly found in modern engines. The assembly also incorporates a venting system that allows air to escape from the tank as fuel is added, preventing a vacuum from forming and ensuring a smooth fueling process.

In summary, the 3918367 filler cap assembly plays a significant role in the fueling process by providing a secure point for fuel entry, maintaining fuel pressure, and allowing for proper ventilation of the fuel tank. Its correct installation and function are important for the overall performance and efficiency of the engine system.

Conclusion

The Cummins 3918367 Filler Cap Assembly is a vital component in the fuel system of commercial trucks, ensuring efficient and safe refueling. Its durable construction, secure sealing mechanism, and compatibility with various Cummins engines make it an essential part for maintaining engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.