This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4895459 Filler Cap is a component designed for use in commercial trucks. Its primary role is within the vehicle’s fuel system, where it serves to seal the fuel tank and facilitate the refueling process. This part is integral to maintaining the integrity of the fuel system, ensuring safe and efficient operation of the truck 1.

Purpose and Function

The filler cap plays a significant role in the truck’s fuel system by providing a secure seal for the fuel tank. This seal is crucial for preventing fuel spillage and contamination, which can lead to safety hazards and engine performance issues. The cap is designed to allow fuel to be added to the tank while preventing the escape of fuel vapors, thereby contributing to the overall efficiency and safety of the refueling process 2.

Key Features

The Cummins 4895459 Filler Cap is constructed with a focus on durability and performance. It is made from high-quality materials that are resistant to wear and corrosion, ensuring long-lasting use in demanding commercial environments. The design of the cap includes features that enhance its sealing capabilities, such as a gasket that provides a tight fit against the fuel tank opening. Additionally, the cap is engineered to be user-friendly, with a mechanism that allows for easy opening and closing during refueling 3.

Benefits

Utilizing the Cummins 4895459 Filler Cap offers several advantages. It contributes to the integrity of the fuel system by providing a reliable seal that prevents leaks and contamination. This enhances the safety of the refueling process and helps maintain the efficiency of the truck’s engine. Furthermore, the cap’s design ensures ease of use, making it straightforward for operators to refuel the vehicle without complications 4.

Installation and Maintenance

Proper installation of the Cummins 4895459 Filler Cap is vital for its effective function. It should be securely fastened to the fuel tank to ensure a tight seal. Regular maintenance, including inspections for wear or damage and cleaning as necessary, is recommended to prolong the cap’s effectiveness and durability. Ensuring the cap is in good condition is a straightforward yet important aspect of vehicle maintenance 1.

Troubleshooting Common Issues

Common issues with filler caps may include leaks or difficulty in opening. If a leak is detected, inspecting the cap for damage or wear is the first step. Replacing a worn or damaged cap can resolve leakage issues. Difficulty in opening the cap may be due to debris or corrosion around the cap’s mechanism. Cleaning the area and ensuring the cap is properly seated can often alleviate this problem 2.

Safety Considerations

When handling and maintaining the filler cap, it is important to adhere to safety protocols. This includes avoiding smoking or open flames near the fuel tank and ensuring the area is well-ventilated during refueling. Proper handling techniques, such as avoiding excessive force when opening or closing the cap, can prevent damage and ensure safe operation 3.

Environmental Impact

The proper use of the Cummins 4895459 Filler Cap contributes to environmental protection by preventing fuel spills. Fuel spills can lead to soil and water contamination, posing risks to ecosystems. Additionally, by maintaining a secure seal on the fuel tank, the cap helps reduce the emission of harmful vapors into the atmosphere, contributing to cleaner air quality 4.

Cummins Overview

Cummins Inc. is a leader in the manufacturing of diesel engines, with a rich history of innovation and quality in the commercial truck industry. The company’s commitment to excellence is evident in its product line, including the Cummins 4895459 Filler Cap, which is designed with the highest standards of performance, durability, and safety in mind.

Cummins Engine Filler Cap Compatibility

The Cummins part number 4895459, a Filler Cap, is designed to fit a variety of Cummins engines. This filler cap is a crucial component for maintaining the integrity of the engine’s fuel system by preventing contamination and ensuring proper fuel management.

Compatible Engines

- B4.5 RGT

- B6.7 CM2670 B153B

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB6.7 CM2250

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISD4.5 CM2220 D108

- ISF3.8 CM2220 AN

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM2880 B115

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

Grouping of Compatible Engines

- ISB Series: ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB6.7 CM2250

- ISBE Series: ISBE CM2150, ISBE CM800, ISBE4 CM850

- ISD Series: ISD4.5 CM2220 D108

- ISF Series: ISF3.8 CM2220 AN

- QSB Series: QSB4.5 CM2250 EC, QSB4.5 CM850 (CM2850), QSB5.9 CM2880 B115, QSB6.7 CM2250, QSB6.7 CM850 (CM2850), QSB7 CM2880 B117

- Others: B4.5 RGT, B6.7 CM2670 B153B

This filler cap is engineered to ensure a secure fit and optimal performance across these engine models, providing a reliable seal to protect the fuel system from external contaminants.

Role of Part 4895459 Filler Cap in Engine Systems

Part 4895459 Filler Cap is an essential component in the lubrication system of an engine. Its primary function is to facilitate the addition of oil to the engine, ensuring that the lubrication system remains adequately filled. This part interfaces with several key components within the engine system, contributing to the overall efficiency and reliability of the engine 1.

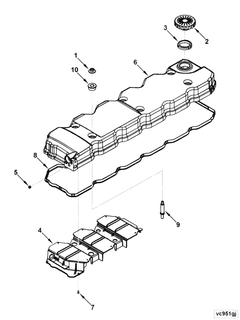

Interaction with the Valve Cover

The Filler Cap is typically mounted on the valve cover, which serves as a protective enclosure for the valve train components. The valve cover not only shields the valves and other internal parts from contaminants but also helps in maintaining the proper pressure within the crankcase. The Filler Cap allows for convenient access to add oil without disturbing the sealed environment of the valve cover 2.

Integration with the Long Block

In the context of a long block—which includes the cylinder block, crankshaft, pistons, and other essential components—the Filler Cap plays a supportive role. It ensures that the long block receives consistent lubrication, which is vital for reducing friction and wear on moving parts. Proper lubrication facilitated by the Filler Cap helps in prolonging the lifespan of the long block components 3.

Relationship with the Arrangement and Valves

The arrangement of engine components, including the positioning of the Filler Cap, is designed to optimize the flow of oil throughout the engine. The Filler Cap must be correctly aligned with the oil fill neck, which is often integrated into the valve cover. This alignment ensures that oil is directed efficiently into the crankcase, where it lubricates the valves, pistons, and other moving parts 4.

Conclusion

In summary, the Cummins 4895459 Filler Cap is a key element in the engine’s lubrication system, working in conjunction with the valve cover, long block, and overall engine arrangement to ensure that all components receive the necessary lubrication for optimal performance and durability.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ ↩ ↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ ↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ ↩ ↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.