This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4931768 Fuel Filler Cap is a component designed for use in commercial trucks. It plays a role in the fueling process by ensuring the secure and efficient transfer of fuel into the vehicle’s tank. This part is integral to maintaining the integrity of the fuel system, contributing to the overall performance and safety of the truck 1.

Purpose and Function

This Cummins part facilitates the fueling process by providing a secure seal that prevents fuel from leaking out of the tank during operation. It allows for the easy insertion of a fuel nozzle while ensuring that fuel vapors are contained within the tank, which helps in reducing emissions and maintaining fuel quality. The cap also plays a role in pressure regulation within the fuel tank, which is important for the proper functioning of the fuel system 2.

Key Features

The Cummins 4931768 Fuel Filler Cap is constructed with durable materials that are resistant to corrosion and wear. Its design includes a robust sealing mechanism that ensures a tight fit on the fuel tank, minimizing the risk of leaks. The cap is also engineered to withstand the pressures and temperatures associated with diesel fuel, making it suitable for heavy-duty applications. Additionally, it features a user-friendly design that allows for easy operation, even with gloves on 3.

Benefits

The use of the Cummins 4931768 Fuel Filler Cap offers several advantages. It contributes to improved fuel efficiency by maintaining the correct pressure within the fuel tank and preventing fuel evaporation. The cap’s design reduces the risk of fuel spills during the refueling process, enhancing safety. It is compatible with various fuel types, providing versatility for different truck models. Moreover, the cap’s durable construction ensures long-term performance, reducing the need for frequent replacements.

Installation and Maintenance

Proper installation of this Cummins part involves ensuring a clean and dry fuel tank opening before attaching the cap. It should be screwed on until it reaches the designated number of turns to achieve a secure seal. Regular maintenance includes inspecting the cap for signs of wear or damage, cleaning it to remove any debris, and ensuring that the sealing surfaces are free from contaminants. If issues arise, such as difficulty in opening or closing the cap, it may be necessary to lubricate the threads or replace the cap if it is damaged.

Troubleshooting Common Issues

Common issues with fuel filler caps include leaks, difficulty in opening or closing, and seal failure. To address leaks, one should check the cap for proper seating and ensure there is no damage to the sealing surfaces. If the cap is hard to open or close, it may require lubrication of the threads or adjustment of the cap’s pressure release valve. In cases where the seal is compromised, replacement of the cap is recommended to maintain the integrity of the fuel system.

Safety Considerations

When handling and maintaining the Cummins 4931768 Fuel Filler Cap, it is important to follow safety protocols to prevent fuel spills, fires, and other hazards. This includes working in a well-ventilated area, avoiding smoking or open flames near the fuel tank, and wearing appropriate personal protective equipment. It is also crucial to ensure that the cap is properly secured after refueling to prevent fuel vapors from escaping.

Environmental Impact

The use of a high-quality fuel filler cap like the Cummins 4931768 contributes to environmental protection by reducing fuel evaporation emissions. A well-sealed cap prevents fuel vapors from escaping into the atmosphere, which helps in minimizing the environmental impact of fuel use. Additionally, by preventing fuel spills, the cap aids in protecting the environment from fuel contamination.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, construction, agricultural, and marine markets. The company is committed to advancing technology for a more sustainable future, offering a wide range of products that meet the demanding requirements of various industries.

Compatibility

The Cummins Fuel Filler Cap 4931768 is designed to ensure the integrity and functionality of the fuel system in various engine models. This part is engineered to fit seamlessly with the following Cummins engine models:

- ISBE CM800

This cap is specifically designed to provide a secure and leak-proof seal for the fuel tank, preventing contamination and ensuring that the engine receives the correct fuel mixture. The cap’s design and material are optimized to withstand the operational conditions of these engines, ensuring durability and reliability over time.

Grouping of Engines

The Cummins Fuel Filler Cap 4931768 is compatible with the ISBE CM800 engine, which is part of the broader range of Cummins engines known for their robust performance and reliability in various applications. This cap is engineered to meet the specific requirements of the ISBE CM800, ensuring a perfect fit and optimal functionality.

Role of Part 4931768 Fuel Filler Cap in Engine Systems

The 4931768 Fuel Filler Cap is an integral component in the fuel system of an engine, ensuring the secure and efficient transfer of fuel into the vehicle’s fuel tank. Its primary function is to seal the fuel tank, preventing fuel vapors from escaping into the atmosphere while allowing fuel to be added during refueling.

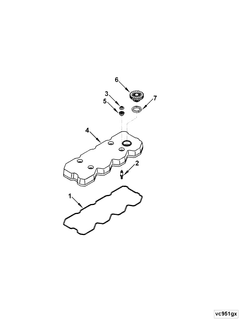

Interaction with the Fuel Tank Cover

The Fuel Filler Cap interfaces directly with the fuel tank cover. When the cap is screwed onto the fuel tank cover, it creates an airtight seal. This seal is essential for maintaining the integrity of the fuel system, ensuring that fuel vapors are contained within the Evaporative Emission Control (EVAP) system. The EVAP system captures these vapors and routes them back into the engine to be burned, reducing emissions and improving fuel efficiency.

Coordination with the Fuel Tank Vent Valve

The Fuel Filler Cap also plays a role in the operation of the fuel tank vent valve. The vent valve is part of the EVAP system and is responsible for regulating the pressure within the fuel tank. When the Fuel Filler Cap is removed for refueling, the vent valve allows air to enter the tank, equalizing pressure and facilitating the smooth flow of fuel. Once refueling is complete and the cap is reattached, the vent valve resumes its role in managing vapor emissions, working in conjunction with the sealed Fuel Filler Cap to maintain system pressure and efficiency.

Conclusion

In summary, the 4931768 Fuel Filler Cap is a key component that ensures the proper functioning of the fuel system by sealing the fuel tank and coordinating with the fuel tank cover and vent valve to manage fuel vapors and system pressure.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.