This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

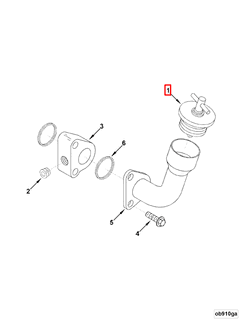

The Cummins 4962891 Filler Cap is a component designed for use in commercial trucks. Its primary function is to facilitate the fueling process while ensuring the integrity of the fuel system. This part plays a role in maintaining the cleanliness and safety of the fuel being added to the truck’s tank.

Basic Concepts of Filler Caps

A filler cap is a cover for the opening of a fuel tank. Its general function in vehicles is to allow fuel to be added to the tank while preventing spills and contamination 1. In the context of a truck’s fuel system, the filler cap also helps maintain pressure and prevent the escape of fuel vapors, contributing to both safety and environmental compliance.

Purpose of the Cummins 4962891 Filler Cap

The Cummins 4962891 Filler Cap is specifically designed to play a role in the fueling process of heavy-duty trucks. It functions by providing a secure seal that prevents fuel spillage during refueling. Additionally, it helps in keeping contaminants out of the fuel tank, which is vital for the efficient operation of the truck’s engine 2.

Key Features

The Cummins 4962891 Filler Cap is constructed from durable materials that are resistant to wear and corrosion. Its design includes features that enhance durability, such as a robust locking mechanism to ensure a tight seal. Unique attributes of this filler cap may include an ergonomic handle for ease of use and a design that accommodates various fueling nozzles.

Benefits

The Cummins 4962891 Filler Cap offers several benefits. It contributes to improved fuel system integrity by providing a reliable seal against spills and contamination. Its ease of use enhances the refueling process, and its durability leads to long-term cost savings by reducing the need for frequent replacements 3.

Installation Process

To install the Cummins 4962891 Filler Cap, first ensure the fuel tank opening is clean and free of debris. Align the cap with the tank opening and turn it clockwise until it locks into place. Tools required may include a socket wrench for any necessary adjustments. Best practices include checking the seal after installation to ensure it is secure.

Troubleshooting Common Issues

Common problems with filler caps include leaks or difficulty in opening. To address leaks, inspect the cap for damage and ensure it is properly seated. If opening is difficult, check for obstructions or debris around the cap and clean as necessary. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

Regular maintenance of the Cummins 4962891 Filler Cap includes cleaning it to remove any buildup and inspecting it for signs of wear or damage. A simple cleaning procedure involves wiping down the cap with a cloth and mild detergent. An inspection checklist should include checking the seal integrity and the condition of the locking mechanism.

Safety Considerations

When handling and maintaining the Cummins 4962891 Filler Cap, it is important to follow safety practices to avoid fuel spills and ensure personal safety. This includes wearing appropriate protective gear, working in a well-ventilated area, and ensuring that the truck’s engine is off during maintenance to prevent accidental starts.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide, providing reliable and efficient solutions for a variety of applications.

Cummins Engine Filler Cap Compatibility

The Cummins part number 4962891, a Filler Cap, is designed to fit seamlessly into the engine systems of various Cummins engines. This filler cap is integral to maintaining the engine’s operational integrity and ensuring that the engine’s cooling system remains sealed and free from contaminants.

4B3.9 Engine

The 4B3.9 engine is one of the models that benefit from the 4962891 filler cap. This cap is engineered to provide a secure fit, ensuring that the engine’s coolant system is properly sealed. The design of the filler cap allows for easy access during maintenance, while also preventing leaks and maintaining the system’s pressure.

6B5.9 Engine

Similarly, the 6B5.9 engine is another model that utilizes the 4962891 filler cap. This cap is specifically crafted to match the contours and requirements of the 6B5.9 engine, ensuring a perfect seal. The cap’s design facilitates straightforward installation and removal, making it an essential component for routine maintenance and ensuring the engine’s cooling system operates efficiently.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines fall under the category of medium-duty and heavy-duty engines, where maintaining a sealed and efficient cooling system is crucial for performance and longevity. The 4962891 filler cap is designed to meet the stringent requirements of these engines, providing a reliable solution for sealing the coolant system.

Role of Part 4962891 Filler Cap in Engine Systems

The 4962891 filler cap is an essential component in the arrangement of various engine systems, ensuring the seamless operation and maintenance of these systems.

Integration with the Air Cleaner

In the context of the air cleaner, the 4962891 filler cap plays a significant role in maintaining the integrity of the air filtration system. By securely sealing the oil fill port, it prevents contaminants from entering the engine’s lubrication system. This ensures that the air cleaner effectively filters incoming air without the risk of oil or debris interfering with its operation. The filler cap’s seal contributes to the overall efficiency of the air cleaner by maintaining a clean environment for the engine’s internal components.

Function within the Oil Fill System

The 4962891 filler cap is directly involved in the oil fill process. It provides a secure closure for the oil tank, allowing for easy and clean addition of lubricant during maintenance. This cap ensures that the oil fill is free from contaminants, which is vital for the longevity and performance of the engine. Additionally, it helps in maintaining the correct oil level by preventing spills and ensuring that the oil is added accurately. The cap’s design often includes features such as a dipstick guide, which aids in precise oil level checks, further enhancing the reliability of the oil fill system.

Overall Contribution to Engine Arrangement

In the broader arrangement of engine components, the 4962891 filler cap contributes to the systematic and efficient operation of the engine. By ensuring that the oil fill process is contaminant-free and accurately managed, it supports the air cleaner’s function and maintains the engine’s lubrication system. This, in turn, helps in achieving optimal engine performance and durability. The cap’s role in sealing the oil tank also aids in preventing oil leaks, which can lead to engine damage and inefficient operation.

Conclusion

In summary, the 4962891 filler cap is a key component that enhances the functionality and reliability of the air cleaner and oil fill systems within the engine arrangement. Its role in maintaining a sealed and contaminant-free environment is crucial for the efficient operation and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.