This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

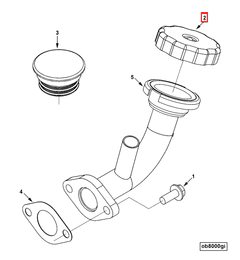

The Cummins 4982561 Filler Cap is a component designed for use in commercial trucks, specifically within the fuel system. Its primary role is to facilitate the addition of fuel to the tank while ensuring that spills and contamination are minimized. This part is integral to maintaining the efficiency and safety of the vehicle’s fuel system 2.

Purpose and Function

The filler cap serves a vital function in the truck’s fuel system by providing a secure closure for the fuel tank. It allows fuel to be added through a nozzle while preventing spills due to its sealing mechanism. Additionally, the cap helps to keep contaminants such as dirt and water out of the fuel tank, which can otherwise lead to engine performance issues 2.

Key Features

The Cummins 4982561 Filler Cap is constructed with a focus on durability and performance. It is made from high-quality materials that resist wear and corrosion, ensuring a long service life. The design includes a robust sealing mechanism that provides a tight fit on the fuel tank, enhancing the overall integrity of the fuel system. Unique attributes such as an ergonomic handle and a tamper-evident seal further contribute to its functionality and security 2.

Benefits

Utilizing the Cummins 4982561 Filler Cap offers several advantages. It enhances the integrity of the fuel system by providing a reliable seal against spills and contamination. The cap is designed for ease of use, featuring a simple twist-off mechanism that allows for quick and convenient refueling. Moreover, it is compatible with Cummins fuel tanks, ensuring a proper fit and function within the system 2.

Installation Process

Installing the Cummins 4982561 Filler Cap requires careful attention to detail to ensure a proper seal and function. The process involves aligning the cap with the fuel tank opening and twisting it into place until it is securely fastened. It is important to use the appropriate tools to avoid damage to the cap or the fuel tank. Safety precautions, such as ensuring the engine is off and the area is well-ventilated, should be observed during installation 2.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 4982561 Filler Cap, regular maintenance is recommended. This includes inspecting the cap for signs of wear or damage, cleaning it to remove any buildup, and replacing it if necessary. Proper maintenance helps to prevent issues such as leaks or difficulty in opening the cap 2.

Troubleshooting Common Issues

Common problems with filler caps can include leaks or difficulty in opening. If a leak is detected, it may be necessary to tighten the cap or replace it if it is damaged. Difficulty in opening the cap could be due to debris around the cap or a faulty sealing mechanism, which may require cleaning or replacement 2.

Safety Considerations

When handling and maintaining the Cummins 4982561 Filler Cap, it is important to observe safety considerations. This includes using proper handling techniques to avoid injury and taking precautions to prevent accidents, such as ensuring the area is well-ventilated when working around fuel 2.

Environmental Impact

The design and functionality of the Cummins 4982561 Filler Cap contribute to minimizing the risk of fuel spills and leaks, which can have a significant environmental impact. By providing a secure seal and preventing contamination, the cap helps to protect the environment from the harmful effects of fuel spills 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications 1.

Compatibility with Cummins Engines

The Cummins part number 4982561, a Filler Cap, is designed to fit seamlessly with a range of Cummins engines. This part is engineered to ensure proper sealing and maintenance of the engine’s oil system. Below is a detailed look at the compatibility of this filler cap with specific Cummins engine models:

B3.3 Series Engines

The Cummins B3.3 engine series is known for its reliability and efficiency. The filler cap 4982561 is specifically designed to fit these engines, ensuring that the oil system remains sealed and protected. This cap is crucial for maintaining the engine’s performance and longevity 1.

QSB3.3 Series Engines

The QSB3.3 series engines, including models such as the QSB3.3 CM2150 and QSB3.3 CM2250 EC, benefit from the use of the 4982561 filler cap. This part is engineered to provide a secure fit, preventing oil leaks and ensuring that the engine operates at optimal efficiency. The compatibility of this filler cap with the QSB3.3 series underscores Cummins’ commitment to quality and reliability 1.

QSB3.3 CM2150 and QSB3.3 CM2250 EC

For the QSB3.3 CM2150 and QSB3.3 CM2250 EC engines, the filler cap 4982561 is a critical component. These engines are designed for heavy-duty applications, and the filler cap plays a vital role in maintaining the integrity of the oil system. The precise engineering of this part ensures that it fits perfectly, providing a reliable seal that is essential for the engine’s performance 1.

Conclusion

The Cummins filler cap 4982561 is a versatile and essential component for a range of Cummins engines, including the B3.3, QSB3.3 CM2150, and QSB3.3 CM2250 EC models. Its design ensures a secure fit, preventing oil leaks and maintaining the engine’s performance and longevity 1.

Role of Part 4982561 Filler Cap in Engine Systems

The Part 4982561 Filler Cap is an essential component in the arrangement of various engine systems, ensuring the smooth operation and maintenance of the engine.

Integration with Oil Fill System

In the oil fill system, the Filler Cap serves as the primary access point for adding lubricant to the engine. It is designed to seal the oil fill port securely, preventing any oil leakage and maintaining the proper oil level within the engine. This is vital for the lubrication of moving parts, reducing friction, and ensuring the longevity of the engine components 2.

Function in the Long Block Assembly

When considering the long block, which includes the engine block, crankshaft, pistons, and other integral components, the Filler Cap plays a significant role in the overall assembly and maintenance process. After the long block is installed, the Filler Cap is one of the first components to be fitted. This allows for the initial filling of the engine with oil, ensuring that all parts are adequately lubricated before the engine is started 2.

Maintenance and Operational Efficiency

During routine maintenance, the Filler Cap is removed to check the oil level and quality. It is also used during oil changes to drain the old oil from the system. The design of the Filler Cap often includes features such as a dipstick tube, which facilitates the monitoring of oil levels without the need to remove the cap entirely 2.

In summary, the Part 4982561 Filler Cap is a fundamental component in the arrangement and operation of engine systems, particularly in the oil fill process and the assembly of the long block. Its proper function ensures the engine remains well-lubricated, operating efficiently, and with reduced wear on internal components 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.