This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

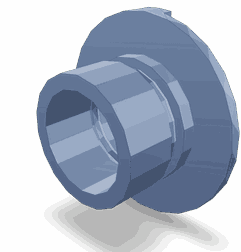

The Cummins 5255310 Filler Cap is a component designed for use in commercial truck operations. Its primary role is to facilitate the secure and efficient refueling of diesel tanks in heavy-duty trucks. This part is integral to maintaining the operational integrity of the vehicle’s fuel system, ensuring that fuel is contained properly and that the refueling process is both safe and straightforward.

Purpose and Function

The 5255310 Filler Cap plays a role in the operation of a truck by serving as the interface between the fuel tank and the refueling source. It allows for the introduction of diesel fuel into the tank while preventing spills and leaks. Additionally, it helps maintain the cleanliness of the fuel by minimizing the ingress of contaminants during refueling 1.

Key Features

The design and construction of the 5255310 Filler Cap incorporate several features that enhance its functionality. It is typically made from durable materials that can withstand the rigors of commercial use. The cap includes a sealing mechanism, often a gasket or O-ring, which ensures a tight seal when the cap is in place. This prevents fuel from escaping and keeps out dirt and moisture. The cap may also feature a venting system to allow air to escape from the tank as it fills, which helps maintain pressure balance and facilitates a smoother refueling process 2.

Benefits

The advantages provided by the 5255310 Filler Cap include effective fuel containment, which is vital for both environmental and safety reasons. Its design promotes ease of use, allowing for quick and hassle-free refueling. The durability of the cap ensures that it can endure frequent use without degradation, contributing to the overall reliability of the truck’s fuel system 3.

Installation Process

To install the 5255310 Filler Cap, one should first ensure that the fuel tank is clean and free of debris. The old cap, if present, should be removed carefully. The new cap should be aligned with the fuel tank opening and screwed on until it is secure. It is important to follow the manufacturer’s torque specifications to ensure a proper seal without over-tightening, which could damage the cap or the tank.

Maintenance Tips

Routine maintenance of the 5255310 Filler Cap involves regular inspection for signs of wear or damage. The sealing surfaces should be kept clean to ensure a good seal. If the cap becomes difficult to turn or shows signs of leakage, it may need to be replaced. Lubricating the threads with a suitable lubricant can help prevent seizing and make future removal easier.

Troubleshooting Common Issues

Frequent problems with the 5255310 Filler Cap may include difficulty in sealing, which can lead to fuel leaks, or the cap becoming stuck. If the cap does not seal properly, checking the condition of the gasket or O-ring and replacing it if necessary can resolve the issue. If the cap is stuck, applying a penetrating lubricant and allowing it to sit for a period before attempting to remove the cap can often help.

Safety Considerations

When handling and working with the 5255310 Filler Cap, it is important to observe safety guidelines. This includes ensuring that the truck’s engine is off and that there are no sources of ignition nearby when refueling. Personal protective equipment, such as gloves and safety glasses, should be worn to protect against fuel splashes. Additionally, it is crucial to follow proper disposal procedures for any waste materials, such as old caps or gaskets, to comply with environmental regulations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history dating back to 1919, Cummins has established itself as a significant player in the commercial truck industry, providing reliable and efficient power systems that meet the demanding requirements of heavy-duty applications.

Cummins Engine Filler Cap Compatibility

The Cummins part 5255310, a Filler Cap, is designed to fit a variety of Cummins engines. This filler cap is essential for maintaining the proper fuel and oil levels in the engine, ensuring optimal performance and longevity. Below is a detailed description of the engines with which this filler cap is compatible.

Compatible Engines

- 15N CM2380 M104B

- F2.8 CM2620 F135B

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

- R2.8 CM2220 R101B

- X11 CM2670 X126B

- X12 CM2670 X121B

- X13 CM2670 X122B

- Z14 CM2670 Z103B

Grouping of Compatible Engines

Group 1: ISF2.8 Models

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

Group 2: ISG12 Models

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

Group 3: QSF2.8 Models

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

Group 4: QSG12 Models

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

Group 5: X11, X12, X13 Models

- X11 CM2670 X126B

- X12 CM2670 X121B

- X13 CM2670 X122B

Group 6: Z14 Model

- Z14 CM2670 Z103B

Group 7: Other Models

- 15N CM2380 M104B

- F2.8 CM2620 F135B

- R2.8 CM2220 R101B

Each of these engines, despite their differences in model and specifications, is designed to work seamlessly with the Cummins part 5255310 Filler Cap. This compatibility ensures that users can maintain their engines with ease, knowing that the filler cap is specifically designed to fit and function correctly with their engine model.

Role of Part 5255310 Filler Cap in Engine Systems

The part 5255310 Filler Cap is an essential component in the operation of various engine systems, particularly in conjunction with the valve cover and valve cover arrangement.

Interaction with Valve Cover

The filler cap interfaces directly with the valve cover, which is a protective enclosure over the valve train components. This cap ensures a sealed environment, preventing contaminants from entering the valve cover cavity. It also maintains the necessary pressure within the valve cover, which is vital for the proper functioning of the Positive Crankcase Ventilation (PCV) system. The PCV system relies on a balance of pressure to effectively vent crankcase gases, and the filler cap plays a significant role in this balance.

Integration with Valve Cover Arrangement

In systems where a valve cover arrangement is employed, which may include multiple valve covers or an integrated design, the filler cap serves to unify these components. It provides a singular point for accessing the valve train area, simplifying maintenance procedures such as oil changes or inspections. The arrangement often includes breather and vent systems, and the filler cap contributes to the efficiency of these systems by ensuring that the valve cover arrangement remains sealed against external elements while allowing controlled venting of gases.

Functional Synergy

The synergy between the filler cap and the valve cover arrangement enhances the overall reliability and performance of the engine. By maintaining a sealed environment, the filler cap helps in preserving the cleanliness of the valve train components, reducing wear and tear. Additionally, it assists in regulating the pressure dynamics within the engine, which is essential for optimal engine operation and longevity.

Conclusion

The Cummins 5255310 Filler Cap is a critical component in the maintenance and operation of heavy-duty truck engines. Its design and functionality ensure secure and efficient refueling, maintain fuel cleanliness, and contribute to the overall reliability of the engine system. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the performance and longevity of the vehicle.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.