This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The T Bolt Clamp 3016666, manufactured by Cummins, is a critical component in the commercial truck industry. This clamp plays a significant role in securing various components, ensuring the structural integrity and efficient functioning of the vehicle.

Basic Concepts and Functionality

A T Bolt Clamp is a type of fastener used in truck maintenance and repair. It operates by applying pressure to secure components together, often used in exhaust systems, piping, and other applications where a strong, reliable connection is required. The T Bolt Clamp 3016666 is designed to provide a secure fit without the need for welding, making it a versatile tool in truck maintenance 1.

Purpose and Role in Truck Operation

The T Bolt Clamp 3016666 serves a specific purpose in truck operations by securing components such as exhaust pipes, hoses, and other parts that require a firm connection. Its function is to maintain the structural integrity of these components, ensuring they remain in place and operate efficiently under various conditions 2.

Key Features

The T Bolt Clamp 3016666 is characterized by several key features that enhance its performance. It is made from durable materials, designed to withstand the rigors of truck operations. The clamp features a unique T-shaped bolt that provides a strong grip, and its design allows for easy installation and removal. Additionally, it is engineered to resist corrosion and wear, ensuring long-lasting performance 3.

Benefits

Using the T Bolt Clamp 3016666 offers several advantages. Its durable construction ensures longevity, while its design facilitates easy installation, reducing downtime during maintenance. The clamp’s reliability in various operating conditions makes it a valuable component for ensuring the efficient operation of commercial trucks.

Installation Process

Installing the T Bolt Clamp 3016666 involves several steps to ensure a secure fit. Begin by positioning the clamp around the components to be secured. Next, tighten the T-shaped bolt using the appropriate tool, ensuring even pressure is applied across the clamp. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which can damage the components or the clamp itself.

Troubleshooting Common Issues

Common issues with T Bolt Clamps may include loosening over time or damage due to corrosion. To address these problems, regularly inspect the clamps for signs of wear or corrosion. If a clamp is found to be loose, re-tighten it according to the manufacturer’s specifications. In cases of corrosion, consider replacing the clamp to maintain the integrity of the connection.

Maintenance Tips

To ensure the longevity and optimal performance of the T Bolt Clamp 3016666, routine maintenance is recommended. This includes regular inspections for signs of wear, corrosion, or loosening. Cleaning the clamp and its surrounding area can prevent the buildup of debris that may affect its performance. Additionally, following the manufacturer’s guidelines for torque specifications during installation and re-tightening can help maintain the clamp’s effectiveness.

Safety Considerations

When working with T Bolt Clamps, it is important to observe safety protocols to prevent accidents and ensure personal safety. Use the appropriate tools for installation and removal to avoid injury. Wear protective gear, such as gloves and safety glasses, to protect against potential hazards. Always follow the manufacturer’s instructions and safety guidelines when handling and installing T Bolt Clamps.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The T Bolt Clamp 3016666 is a testament to Cummins’ dedication to providing reliable and high-performance components for the trucking industry.

Cummins T Bolt Clamp Part 3016666 Compatibility

The Cummins T Bolt Clamp part number 3016666 is designed to fit a variety of Cummins engines, ensuring secure fastening and stability in various applications. This part is compatible with the following engines:

- 4B3.9

- 6B5.9

- G5.9

- KTA19GC CM558

- KTA38GC CM558

- QSB7 CM2880 B117

- QST30 CM552

- X12 CM2670 X121B

- X13 CM2670 X122B

For engines within the KTA19GC CM558 and KTA38GC CM558 series, the T Bolt Clamp part 3016666 is essential for maintaining the integrity of the engine’s mounting and securing components. Similarly, for the QSB7 CM2880 B117 and QST30 CM552 engines, this part ensures that all bolted connections are firmly held, contributing to the overall reliability and performance of the engine.

In the case of the X12 CM2670 X121B and X13 CM2670 X122B engines, the T Bolt Clamp part 3016666 plays a crucial role in securing various parts, ensuring that the engine operates smoothly and efficiently. This part is also suitable for the 4B3.9 and 6B5.9 engines, providing the necessary support and stability for these engine models.

Overall, the Cummins T Bolt Clamp part 3016666 is a versatile component that enhances the functionality and durability of the listed engines, making it an indispensable part for maintenance and repair.

Role of Part 3016666 T Bolt Clamp in Engine Systems

The part 3016666 T Bolt Clamp is integral to the secure and efficient operation of various engine components. It plays a significant role in maintaining the integrity of connections and ensuring the smooth functioning of the engine system.

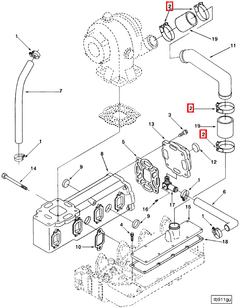

Air Crossover Connection

In the air crossover connection, the T Bolt Clamp ensures a tight and leak-free seal. This is essential for maintaining the correct airflow between the turbocharger and the air intake system. Proper sealing prevents any loss of air pressure, which could otherwise lead to reduced engine performance.

Air Intake Mounting Crossover

For the air intake mounting crossover, the T Bolt Clamp secures the connection points, ensuring that the air intake system remains firmly attached to the engine. This stability is vital for consistent air delivery to the engine, which is necessary for optimal combustion and power output.

Turbocharger Arrangement

Within the turbocharger arrangement, the T Bolt Clamp is used to secure various hoses and pipes that connect to the turbocharger. This includes the connections to the air intake and exhaust systems. Secure fittings are necessary to withstand the high pressures and temperatures associated with turbocharger operation.

Filter and Full Flow Oil System

In the filter and full flow oil system, the T Bolt Clamp ensures that oil lines and filter connections are securely fastened. This prevents oil leaks and maintains the proper flow of oil throughout the engine, which is essential for lubrication and cooling of engine components.

Fuel Control Module

For the fuel control module, the T Bolt Clamp secures fuel lines and connections, ensuring that fuel is delivered consistently and without leaks. This is important for maintaining the correct fuel-to-air ratio, which is critical for engine efficiency and performance.

Turbocharger Location

At the turbocharger location, the T Bolt Clamp is used to secure the turbocharger to its mounting points. This ensures that the turbocharger remains stable and aligned correctly, which is necessary for efficient operation and to prevent damage from vibrations.

Valve and Pressure Regulator

Finally, in the valve and pressure regulator systems, the T Bolt Clamp secures connections that control the flow of air and fuel. This ensures that these systems operate within their designed parameters, contributing to the overall efficiency and reliability of the engine.

Conclusion

The T Bolt Clamp 3016666 by Cummins is a vital component in the maintenance and operation of commercial trucks. Its durable construction, ease of installation, and reliable performance make it an essential tool for securing various engine components. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part in truck operations.

-

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles (Second Edition). SAE International.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles (Second Edition). SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.