This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Clamp 3022142 by Cummins is a specialized component designed for use in commercial truck operations. Its purpose is to secure and maintain the integrity of various tubing systems within these vehicles. The significance of this tube clamp lies in its ability to ensure reliable and efficient operation of critical systems, contributing to the overall performance and safety of commercial trucks 1.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to join and secure tubing in automotive and industrial applications. They function by compressing the tubing between a band and a saddle, creating a tight seal that prevents leaks and maintains system pressure. Tube clamps are commonly used in fuel lines, brake systems, and exhaust systems, among other applications, providing a versatile solution for connecting and securing tubing in various configurations 2.

Purpose of the 3022142 Tube Clamp in Truck Operations

The 3022142 Tube Clamp by Cummins plays a specific role in the operation of commercial trucks by securing tubing in systems such as fuel lines, hydraulic systems, and pneumatic systems. Its application ensures that these systems operate under the required pressure and without leaks, which is vital for the efficient and safe functioning of the truck. The clamp’s design allows it to adapt to different tubing diameters and materials, making it a versatile component in truck maintenance and repair 3.

Key Features of the 3022142 Tube Clamp

The 3022142 Tube Clamp is engineered with several design elements and materials that enhance its effectiveness and durability. It is constructed from high-strength materials to withstand the rigors of commercial truck operations. The clamp features a serrated band that provides a secure grip on the tubing, preventing slippage and ensuring a tight seal. Additionally, its design allows for easy installation and removal, facilitating maintenance procedures 4.

Benefits of Using the 3022142 Tube Clamp

Utilizing the 3022142 Tube Clamp offers several advantages in commercial truck operations. It contributes to improved system integrity by ensuring secure and leak-free connections. The clamp’s design facilitates ease of installation, reducing downtime during maintenance. Furthermore, its durability and resistance to corrosion extend the lifespan of the tubing systems, leading to cost savings and increased operational efficiency.

Installation Process

To install the 3022142 Tube Clamp correctly, begin by ensuring the tubing is clean and free of debris. Position the clamp around the tubing, aligning it with the saddle. Use the provided tool to tighten the band until the desired compression is achieved, ensuring a secure fit without damaging the tubing. Verify the connection by checking for leaks and proper system pressure. Follow these steps to ensure optimal performance and safety.

Troubleshooting Common Issues

Typical problems with tube clamps may include leaks, improper compression, or damage to the tubing. To address these issues, first, inspect the clamp and tubing for signs of wear or damage. Ensure the clamp is correctly positioned and tightened. If leaks persist, consider replacing the clamp or the section of tubing. Regular inspections and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

To prolong the lifespan and ensure the reliable operation of the 3022142 Tube Clamp, regular maintenance is recommended. Inspect the clamp and tubing during routine checks for signs of wear, corrosion, or leaks. Clean the clamp and surrounding areas to remove dirt and debris that could affect performance. Replace the clamp if it shows signs of significant wear or if the tubing requires replacement. Adhering to these maintenance practices will help maintain the integrity of the tubing systems in commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

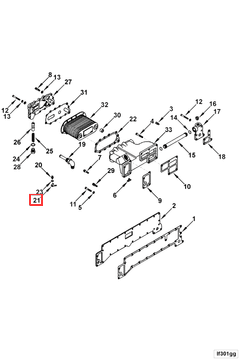

Tube Clamp 3022142 in Cummins Engines

The Tube Clamp 3022142, manufactured by Cummins, is a crucial component in ensuring the integrity and functionality of various engine systems. This part is designed to secure and stabilize tubes and pipes within the engine, preventing leaks and maintaining the structural integrity of the system.

Application in Cummins Engines

-

V903 Engine Family: The Tube Clamp 3022142 is integral to the V903 engine family, where it is used to secure coolant and oil lines. Its robust design ensures that these lines remain firmly in place, even under the high-stress conditions typical of engine operation.

-

Other Cummins Engines: Beyond the V903, this tube clamp is also utilized in other Cummins engine models. Its versatility allows it to fit seamlessly into various engine configurations, providing a reliable solution for securing critical tubing.

The Tube Clamp 3022142 is engineered to withstand the demanding environments within engines, ensuring long-lasting performance and reliability. Its application across multiple engine types highlights its importance in maintaining the overall efficiency and safety of Cummins engines.

Role of Part 3022142 Tube Clamp in Engine Systems

In the orchestration of an engine’s subsystems, the 3022142 Tube Clamp assumes a significant role by ensuring the secure and efficient connection of various components. This clamp is instrumental in maintaining the integrity of fluid pathways, which is essential for the optimal performance of the engine.

Integration with the Filter

The 3022142 Tube Clamp is utilized to connect the lubricating oil filter to the engine’s oil passages. This connection is vital for the filtration process, where contaminants are removed from the oil, ensuring that only clean lubricant reaches the engine’s moving parts. A secure clamp connection prevents leaks and maintains consistent oil flow, which is necessary for the filter to operate effectively.

Lubricating Oil System

Within the lubricating oil system, the 3022142 Tube Clamp facilitates the connection between the oil pump and the distribution lines. This ensures that pressurized oil is delivered to all critical engine components, such as bearings, pistons, and camshafts. The clamp’s role here is to provide a leak-free seal, which is paramount for maintaining oil pressure and ensuring that all parts receive adequate lubrication.

Lubricating Oil Bypass Tube

The lubricating oil bypass tube is a component that allows oil to bypass the filter when it becomes clogged, ensuring that the engine continues to receive lubrication even under adverse conditions. The 3022142 Tube Clamp is used to connect this bypass tube to the main oil lines. This connection is essential for the system’s fail-safe mechanism, allowing the engine to operate without interruption, even if the filter becomes obstructed.

Oil Cooler

The oil cooler is a heat exchanger that reduces the temperature of the lubricating oil, which can become excessively hot during engine operation. The 3022142 Tube Clamp is employed to connect the oil cooler to the engine’s oil circuit. This ensures that cooled oil is efficiently circulated back into the engine, preventing overheating and maintaining the oil’s viscosity for optimal lubrication.

Conclusion

In summary, the 3022142 Tube Clamp is a fundamental component in the secure and efficient operation of an engine’s fluid systems. Its applications across various connections within the engine ensure that fluid pathways remain intact, contributing to the engine’s longevity and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.