This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

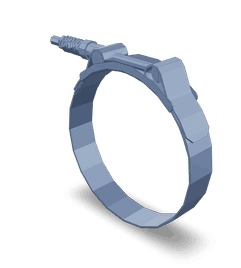

The T-Bolt Clamp 3026914, manufactured by Cummins, is a component designed for use in commercial trucks. It plays a role in securing various components and systems within these vehicles. Cummins is recognized for producing reliable and durable parts that contribute to the efficient operation of heavy-duty vehicles.

Basic Concepts of T-Bolt Clamps

A T-Bolt Clamp is a type of fastener used in mechanical systems to secure components in place. It consists of a bolt with a T-shaped head that fits into a slot or groove, providing a strong and stable connection. T-Bolt Clamps are commonly used in applications where vibration or movement could loosen traditional fasteners, offering a more secure attachment method.

Purpose of the 3026914 T-Bolt Clamp in Truck Operation

The 3026914 T-Bolt Clamp is utilized in the operation and maintenance of commercial trucks to secure components within various systems. Its application can be found in areas where a robust and reliable fastening solution is required to withstand the rigors of heavy-duty truck environments. This includes securing hoses, pipes, and other components that are subject to vibration and movement.

Key Features

The 3026914 T-Bolt Clamp is constructed with specific design and material features that enhance its functionality. It is made from high-quality materials that offer durability and resistance to corrosion. The clamp’s dimensions are tailored to fit specific applications, ensuring a secure and snug fit. Unique attributes such as its T-shaped bolt head provide additional stability and resistance to loosening.

Benefits of Using the 3026914 T-Bolt Clamp

Utilizing the 3026914 T-Bolt Clamp offers several advantages. Its durable construction ensures longevity, even under demanding conditions. The design of the clamp facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its reliability in securing components contributes to the overall safety and efficiency of truck operations.

Installation Process

Installing the 3026914 T-Bolt Clamp involves a series of steps to ensure a secure fit. Begin by positioning the clamp over the component to be secured. Insert the T-shaped bolt into the corresponding slot or groove. Use the appropriate tools to tighten the bolt, ensuring that the clamp is firmly in place without over-tightening, which could damage the component or the clamp itself. Follow best practices for torque specifications to maintain the integrity of the fastening.

Troubleshooting Common Issues

Common issues with T-Bolt Clamps may include loosening over time or corrosion in certain environments. To address loosening, periodically check the tightness of the clamp and re-tighten as necessary. In cases of corrosion, cleaning the affected areas and applying a corrosion-resistant coating can help prevent further degradation. Regular inspections can identify these issues early, allowing for timely maintenance.

Maintenance Tips

To prolong the lifespan and effectiveness of the 3026914 T-Bolt Clamp, regular maintenance checks are recommended. Inspect the clamp for signs of wear, corrosion, or loosening during routine maintenance intervals. Cleaning the clamp and its surrounding area can prevent the buildup of debris that may affect its performance. Applying a protective coating can also enhance its resistance to environmental factors.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions systems. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Their product range is designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions.

T-Bolt Clamp 3026914 Compatibility with Cummins Engines

The T-Bolt Clamp part number 3026914, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for securing components within the engine assembly, ensuring stability and proper function. Here is a detailed look at its compatibility with specific Cummins engines:

Compatibility with 4B3.9 and 6B5.9 Engines

The T-Bolt Clamp 3026914 is compatible with the 4B3.9 and 6B5.9 engines. These engines are part of the Cummins B Series, known for their robust performance and reliability in various applications. The T-Bolt Clamp is used to secure certain components within these engines, ensuring that they remain firmly in place during operation. This is particularly important in maintaining the integrity of the engine’s internal mechanisms.

Compatibility with K19, K38, and K50 Engines

The T-Bolt Clamp 3026914 also fits the K19, K38, and K50 engines. These engines are part of the Cummins K Series, which is widely used in heavy-duty applications, including trucks and industrial machinery. The T-Bolt Clamp is essential in these engines for securing various parts, contributing to the overall durability and efficiency of the engine. Its design ensures that components are held securely, reducing the risk of mechanical failure and enhancing the engine’s longevity.

Grouping for Enhanced Understanding

When considering the compatibility of the T-Bolt Clamp 3026914, it is useful to group the engines based on their series. The B Series (4B3.9 and 6B5.9) and the K Series (K19, K38, and K50) both benefit from this part in similar ways, ensuring that critical components are held in place. This grouping helps in understanding the broader application of the T-Bolt Clamp across different engine models, highlighting its versatility and importance in maintaining engine integrity.

Role of Part 3026914 T-Bolt Clamp in Engine Systems

The T-Bolt Clamp, identified by part number 3026914, is an essential component in the assembly and maintenance of various engine systems. Its primary function is to secure and maintain the integrity of connections within the air intake and exhaust systems.

Air Cleaner Assembly

In the air cleaner assembly, the T-Bolt Clamp is used to ensure a tight and leak-free connection between the air cleaner housing and its associated plumbing. This secure fit is vital for maintaining the efficiency of the air filtration process, ensuring that only clean air enters the engine.

Air Cleaner Connection

For the air cleaner connection, the T-Bolt Clamp plays a significant role in joining the air cleaner to the intake manifold or carburetor. This connection must be robust to prevent any air leaks, which could otherwise lead to inefficient engine performance and increased emissions.

Air Cleaner Plumbing

In the context of air cleaner plumbing, the T-Bolt Clamp is employed to connect various hoses and tubes that route air from the air cleaner to different parts of the engine system. This includes connections to the throttle body, intake tract, and other components where clean air is required. The clamp ensures that these connections remain secure under varying engine conditions, such as vibrations and temperature changes.

General Air System Components

Across general air system components, the T-Bolt Clamp is utilized to maintain the structural integrity of the air passages. Whether connecting the air cleaner to the engine block or securing hoses within the air intake system, the clamp ensures that all connections are maintained under operational stress.

The consistent use of the T-Bolt Clamp across these applications underscores its importance in ensuring the reliability and performance of the engine’s air intake system.

Conclusion

The 3026914 T-Bolt Clamp is a vital component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its design and functionality contribute to the secure fastening of various components, enhancing the reliability and efficiency of truck operations. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.