This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

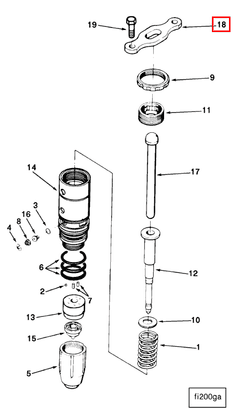

The Cummins Injector Clamp 3028346 is a critical component designed for use in heavy-duty trucks, specifically within the fuel injection system. This part ensures the secure placement of fuel injectors, contributing to the engine’s efficiency and reliability. Understanding its function and maintenance is essential for maintaining the performance standards of heavy-duty trucks.

Basic Concepts of Injector Clamps

An injector clamp is a vital part of the fuel injection system, securing the injector to the fuel rail. This ensures a stable connection, preventing leaks and ensuring consistent fuel delivery. The precise operation of fuel injectors, which deliver fuel into the engine’s combustion chambers, relies on the secure fit provided by the clamp 1.

Role of the Injector Clamp in Truck Operation

The 3028346 Injector Clamp is crucial for the proper functioning of the fuel injection system in trucks. It maintains the system’s integrity by ensuring a tight seal, which is necessary for efficient fuel delivery to the engine. This component is involved in delivering fuel at the correct pressure and timing, which are essential for engine performance and fuel efficiency 2.

Key Features

The Cummins Injector Clamp 3028346 is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures of the fuel injection system. The clamp’s design includes features that enhance its performance and durability, such as a precise fit that ensures a secure hold on the injector and resistance to wear and corrosion 3.

Benefits

The use of the Cummins Injector Clamp 3028346 in a truck’s fuel injection system can lead to several benefits. These include improved fuel efficiency due to consistent fuel delivery, enhanced engine performance as a result of precise fuel injection, and increased reliability of the fuel injection system. The clamp’s design and materials contribute to these benefits by ensuring a secure and leak-free connection between the injector and the fuel rail 4.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Cummins Injector Clamp 3028346, it is important to be aware of common issues that may arise. Signs of wear or failure can include leaks in the fuel system or inconsistent engine performance. Regular maintenance, such as inspecting the clamp for signs of wear and ensuring it is securely fastened, can help prevent these issues. Additionally, following the manufacturer’s guidelines for maintenance and replacement can contribute to the continued efficient operation of the fuel injection system 5.

Compatibility

The Injector Clamp 3028346 is compatible with various Cummins engines, including the L10 MECHANICAL and QSK19 CM500. It is specifically engineered to fit the unique design and requirements of these engine models, ensuring that the injectors are held firmly in place, which is crucial for the engine’s operation, especially under high-stress conditions 6.

Conclusion

The Cummins Injector Clamp 3028346 plays a significant role in the fuel delivery system of heavy-duty trucks. Its function in securing the injector and ensuring efficient fuel delivery underscores its importance in both standard and performance-oriented engine setups. Regular maintenance and understanding its role in the engine system are key to ensuring the longevity and efficiency of the vehicle.

-

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Cummins Injector Clamp 3028346 Compatibility. Retrieved from Cummins official website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.