This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

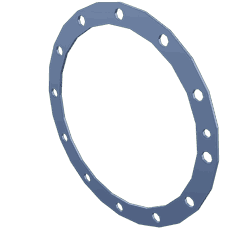

The Cummins 3031753 Clamping Ring is a component designed to secure and maintain the integrity of connections within commercial trucks. Its role is significant in ensuring the reliable operation of various truck systems, particularly in maintaining secure and leak-free connections.

Basic Concepts of Clamping Rings

Clamping rings are mechanical components used to hold two or more parts together securely. They function by applying pressure to seal surfaces, preventing leaks and ensuring that components remain aligned and stable under operational conditions. These rings are essential in systems where vibrations and dynamic loads are common, as they help maintain the structural integrity and efficiency of the connections 1.

Purpose of the 3031753 Clamping Ring

This Cummins part is specifically designed to play a role in the engine or other systems of a truck by securing components such as hoses, pipes, or fittings. It ensures that these parts remain firmly in place, which is vital for the proper functioning of the engine and other systems. By maintaining a tight seal, it helps prevent leaks and ensures that fluids and gases are directed correctly through the system 2.

Key Features

The design and material characteristics of the 3031753 Clamping Ring contribute to its effectiveness and durability. It is typically made from high-strength materials that can withstand the rigors of truck operation, including exposure to high temperatures, pressure fluctuations, and mechanical stress. The ring’s design ensures a uniform distribution of clamping force, which enhances the seal’s integrity and longevity 3.

Benefits

Using the 3031753 Clamping Ring provides several advantages. It improves sealing by ensuring a tight fit between components, which reduces the risk of leaks. Additionally, it minimizes vibration by securely holding parts in place, which can enhance the overall stability and performance of the truck’s systems. The enhanced component security it offers contributes to the reliability and efficiency of the truck’s operation.

Installation Process

Proper installation of the 3031753 Clamping Ring involves several steps to ensure correct fitting. First, the surfaces to be clamped should be clean and free of any debris. The ring should be positioned correctly around the components, and then the clamping mechanism should be tightened gradually to apply even pressure. Using the appropriate tools and following the manufacturer’s guidelines ensures that the ring is installed correctly and functions as intended.

Common Issues and Troubleshooting

Typical problems associated with clamping rings include leaks and component misalignment. These issues can often be traced back to improper installation or wear and tear on the ring. Troubleshooting methods may involve re-tightening the ring, inspecting for damage, or replacing the ring if it is worn out. Regular checks can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

Regular inspection and maintenance of the 3031753 Clamping Ring are recommended to ensure ongoing performance and longevity. This includes checking for signs of wear, ensuring that the clamping force is consistent, and verifying that there are no leaks. Periodically reviewing the installation and condition of the ring can help prevent issues and maintain the efficiency of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to innovation and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Cummins Part 3031753: Clamping Ring Compatibility

This Cummins part is designed to fit seamlessly within a variety of engine configurations. This part is integral to ensuring the proper sealing and functionality of the engine components it supports. Below is a detailed overview of its compatibility with the specified engines:

N14 CELECT and N14 CELECT PLUS

The N14 CELECT and N14 CELECT PLUS engines are known for their robust design and advanced electronic controls. The Clamping Ring part 3031753 is specifically engineered to fit these engines, providing a reliable seal that prevents leaks and maintains optimal engine performance. This part is crucial in maintaining the integrity of the engine’s internal systems, ensuring that the engine operates efficiently and reliably.

N14 MECHANICAL

The N14 MECHANICAL engine, which relies on mechanical controls rather than electronic systems, also benefits from the use of the Clamping Ring part 3031753. This part is designed to fit the mechanical components of the engine, ensuring that the engine’s sealing and structural integrity are maintained. The Clamping Ring is essential in preventing leaks and ensuring that the engine operates smoothly.

NH/NT 855

The NH/NT 855 engines, known for their versatility and power, also require the Clamping Ring part 3031753 to maintain their performance. This part is designed to fit the specific components of these engines, ensuring that the engine’s sealing and structural integrity are maintained. The Clamping Ring is essential in preventing leaks and ensuring that the engine operates efficiently.

Role of Part 3031753 Clamping Ring in Engine Systems

This part is an essential component in ensuring the secure attachment and optimal performance of various engine components. Its primary function is to maintain the integrity and alignment of rotating assemblies within the engine system.

Flex Disc Drive

In the Flex Disc Drive system, the Clamping Ring plays a significant role by securing the flex disc to the input shaft. This ensures that the disc remains firmly in place, allowing for smooth power transmission from the engine to the transmission. The ring’s precise fit and strong grip help mitigate any potential slippage or misalignment, which could otherwise lead to inefficient power transfer and increased wear on the components.

Flexplate

When integrated with the Flexplate, the Clamping Ring ensures that the flexplate is correctly positioned and held in place relative to the crankshaft and torque converter. This secure attachment is vital for the consistent operation of the automatic transmission system. The ring’s design allows for the flexplate to flex slightly under load without losing its secure connection, thereby enhancing the durability and reliability of the transmission system.

Flexplate Assembly

In a Flexplate Assembly, the Clamping Ring contributes to the overall stability and performance of the assembly. By clamping the flexplate to the crankshaft, it ensures that all components within the assembly operate in unison. This synchronization is essential for the smooth engagement and disengagement of the transmission, reducing the likelihood of harsh shifts or transmission failures.

Flywheel

For engines equipped with a manual transmission, the Clamping Ring is instrumental in attaching the Flywheel to the crankshaft. This secure connection is necessary for the effective transfer of engine power to the transmission via the clutch. The ring’s robust design handles the high torque and rotational forces generated during operation, ensuring that the flywheel remains firmly attached and operates efficiently.

Conclusion

Overall, the 3031753 Clamping Ring is a key component in maintaining the structural integrity and operational efficiency of various engine systems, facilitating reliable power transmission and enhancing the longevity of interconnected components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.