This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3031989 Tube Clamp is a specialized component designed for use in commercial truck operations. Its purpose is to secure and connect tubing systems, ensuring the integrity and efficiency of various truck systems. This clamp is significant in maintaining the performance and reliability of commercial vehicles, contributing to their overall operational effectiveness.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold and connect tubing in automotive and industrial applications. They function by providing a secure and adjustable connection, allowing for the efficient transfer of fluids or gases within a system. Tube clamps are crucial in applications where flexibility, ease of installation, and the ability to accommodate different tubing sizes are required 1.

Purpose of the Cummins 3031989 Tube Clamp

The Cummins 3031989 Tube Clamp plays a specific role in the operation of commercial trucks by securing tubing in various systems such as fuel lines, hydraulic systems, and cooling systems. Its application ensures that these systems operate efficiently and reliably, contributing to the overall performance of the truck.

Key Features

The Cummins 3031989 Tube Clamp is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes adjustable bands that allow for a secure fit on different tubing sizes, and it features a robust construction that can withstand the demanding conditions of commercial truck operations.

Benefits

The Cummins 3031989 Tube Clamp offers several benefits, including improved system integrity through secure tubing connections. It facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its design allows for straightforward maintenance, enabling quick inspections and adjustments as needed.

Installation Process

Installing the Cummins 3031989 Tube Clamp involves several steps to ensure a secure fit. Begin by cleaning the tubing to remove any debris or contaminants. Position the clamp around the tubing, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, achieving a snug fit without over-tightening, which could damage the tubing. Verify the connection by checking for leaks or looseness.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or loose connections. To address these problems, first, inspect the clamp and tubing for any signs of damage or wear. Ensure the clamp is properly tightened and aligned. If leaks persist, consider replacing the clamp or inspecting the tubing for integrity. Regular maintenance and inspections can help prevent these issues 2.

Maintenance Tips

Regular maintenance of the Cummins 3031989 Tube Clamp is crucial for ensuring long-term performance and reliability. Inspect the clamp and tubing during routine maintenance checks, looking for signs of wear, corrosion, or looseness. Clean the clamp and surrounding areas to prevent the buildup of debris that could affect performance. Follow manufacturer recommendations for inspection intervals and care instructions.

Compatibility and Applications

The Cummins 3031989 Tube Clamp is designed for use in various commercial truck systems, including fuel lines, hydraulic systems, and cooling systems. It is compatible with a range of tubing sizes and materials, making it versatile for different applications within the commercial trucking industry.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and automotive components, with a history of innovation and commitment to quality. The company’s products are known for their reliability and performance, contributing to the efficiency and effectiveness of commercial vehicles. Cummins’ dedication to quality and innovation is evident in their range of components, including the Cummins 3031989 Tube Clamp 3.

Compatibility with Cummins Engines

The Tube Clamp 3031989, manufactured by Cummins, is a versatile component designed to fit a range of Cummins engines. This part is integral for securing and maintaining the integrity of various engine systems. Below is a detailed overview of its compatibility with specific Cummins engines:

GTA38 G CMEICS G116C

The Tube Clamp 3031989 is compatible with the GTA38 G CMEICS G116C engine. This compatibility ensures that the clamp can be effectively used to secure tubes and hoses, maintaining the engine’s operational efficiency and safety.

K38, K50, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

The Tube Clamp 3031989 is also suitable for the K38, K50, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines benefit from the clamp’s ability to secure various components, ensuring that the engine operates smoothly and reliably.

QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

For the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108 engines, the Tube Clamp 3031989 is designed to fit seamlessly. This compatibility is crucial for maintaining the structural integrity of the engine’s components, ensuring optimal performance and longevity.

Each of these engines, despite their differences, relies on the Tube Clamp 3031989 to secure and protect critical components, ensuring that the engine operates efficiently and safely.

Role of the 3031989 Tube Clamp in Engine Systems

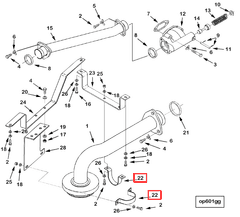

The 3031989 Tube Clamp is instrumental in securing and maintaining the integrity of various oil and lubrication systems within an engine. It is specifically designed to ensure a tight and reliable connection between different components, facilitating efficient fluid transfer and system performance.

In the context of the cooler, the Tube Clamp is used to connect the cooler lines, ensuring that the engine oil is effectively cooled before it is recirculated. This helps in maintaining optimal engine temperature and prolonging the life of the engine components.

For the engine oil system, the Tube Clamp plays a significant role in securing connections within the EBM-PAN and the oil pan gasket kit. It ensures that there are no leaks in the oil suction area, which is vital for maintaining proper oil pressure and lubrication.

In the lub oil plumbing and lub oil tubing, the Tube Clamp is essential for connecting various sections of tubing. This includes the MTG. points where different tubes meet, ensuring a seamless flow of lubricating oil throughout the system.

The Tube Clamp is also utilized in the oil suction process, particularly in securing the oil suction mounting and oil suction tube mounting. This ensures that the oil is efficiently drawn from the pan and circulated through the engine, reducing the risk of cavitation and ensuring consistent lubrication.

Furthermore, in the lubricating oil suction system, the Tube Clamp is critical for maintaining the integrity of connections between the suction mounting tube and other components. This ensures that the lubricating oil is effectively suctioned from the pan and delivered to the necessary parts of the engine, enhancing overall engine performance and reliability.

Conclusion

The Cummins 3031989 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure and reliable connections in various systems, contributing to the overall performance and reliability of the vehicles. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Springer, 2014.

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.