This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The T Bolt Clamp 3040793, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part plays a role in ensuring the smooth operation of truck components.

Basic Concepts and Functionality

A T Bolt Clamp is a type of fastener used to secure pipes, tubes, and other cylindrical objects. It operates by clamping the object between a saddle and a bolt, which is tightened to create a secure hold. In the context of truck components, T Bolt Clamps are often used to attach hoses, pipes, and other parts to the truck’s frame or other structures, ensuring they remain in place under various driving conditions 1.

Role and Purpose

This part is specifically designed to secure various components within a truck’s system. Its role is to provide a stable and reliable connection between parts, which is vital for the overall functionality and safety of the vehicle. By securing components such as hoses and pipes, it helps maintain the integrity of the truck’s systems, ensuring they operate as intended 2.

Key Features

The T Bolt Clamp 3040793 is constructed from high-quality materials, which contribute to its durability and performance. Its design includes a saddle that fits around the object being clamped and a bolt that is tightened to secure the clamp in place. The clamp’s material composition and design elements are tailored to withstand the rigors of commercial truck operations, providing a reliable connection that can endure various environmental and operational conditions.

Benefits

Using this Cummins part offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The design of the clamp allows for easy installation, minimizing downtime during maintenance procedures. Additionally, the secure connection it provides contributes to the efficient operation of the truck’s systems, enhancing overall performance 3.

Installation Process

Installing the T Bolt Clamp 3040793 involves positioning the saddle around the object to be clamped, aligning the bolt, and tightening it to the appropriate torque specification. This process may require the use of tools such as a torque wrench to ensure the clamp is secured properly without over-tightening, which could damage the clamp or the object being secured.

Common Issues and Troubleshooting

Frequent problems associated with the T Bolt Clamp 3040793 may include loosening over time due to vibration or improper installation. To address these issues, regular inspections should be conducted to ensure the clamp remains securely tightened. If loosening is detected, the clamp should be re-tightened to the manufacturer’s specified torque. In cases where the clamp or the object being secured is damaged, replacement may be necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the T Bolt Clamp 3040793, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage, ensuring the clamp remains securely tightened, and addressing any issues promptly to prevent further complications.

Safety Considerations

When handling, installing, or maintaining the T Bolt Clamp 3040793, it is important to observe safety guidelines. This includes using the appropriate tools for installation and maintenance, wearing personal protective equipment (PPE) as necessary, and ensuring the truck is safely supported if working underneath it. Adhering to these safety precautions helps prevent accidents and ensures a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and components designed to enhance the performance and efficiency of heavy-duty trucks.

Cummins T Bolt Clamp 3040793 Compatibility

This part is a critical component in the engine assembly, ensuring secure fastening and stability of various parts. It is designed to fit seamlessly with several Cummins engine models, enhancing their operational efficiency and durability.

N14 CELECT and N14 MECHANICAL Engines

The T Bolt Clamp 3040793 is compatible with both the N14 CELECT and N14 MECHANICAL engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The clamp’s precise fit and strength are essential for maintaining the integrity of the engine’s components, ensuring that parts remain securely fastened under various operating conditions.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the use of the Cummins T Bolt Clamp 3040793. This engine series is recognized for its power and efficiency, making it a popular choice in various industrial and commercial applications. The clamp’s design ensures that the engine’s components are held firmly in place, contributing to the overall performance and longevity of the engine.

By integrating the T Bolt Clamp 3040793 into these engines, Cummins ensures that users can rely on a secure and stable assembly, which is crucial for the engines’ optimal performance and durability.

Role of Part 3040793 T Bolt Clamp in Engine Systems

The 3040793 T Bolt Clamp is an essential component in the assembly and securement of various engine system components. It facilitates the robust connection and mounting of several critical parts, ensuring the integrity and efficiency of the engine’s performance.

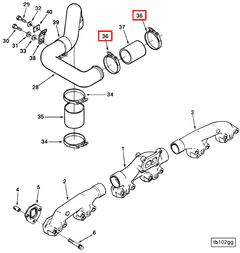

Air Crossover Connection and Mounting

In the air crossover system, the T Bolt Clamp plays a significant role in securing the air crossover connection. This ensures a leak-free passage of air between the turbochargers, which is vital for balanced air distribution and optimal engine performance. Additionally, it aids in the stable mounting of the air crossover, reducing vibrations and potential disconnections during operation.

Air Tube Plumbing

For the air tube plumbing, the T Bolt Clamp is used to connect and secure the air tubes that route air from the turbochargers to the intake manifold. This securement is important for maintaining consistent air pressure and flow, which directly impacts the engine’s combustion efficiency and power output.

Turbocharger Arrangement and Mounting

In the arrangement of turbochargers, the T Bolt Clamp is instrumental in mounting the turbochargers to their designated locations. It ensures that the turbochargers are firmly attached to the engine block or exhaust manifold, preventing any movement that could lead to misalignment or damage. This stable mounting is essential for the turbochargers to operate efficiently and withstand the high-pressure environments they are subjected to.

Exhaust Manifold Connection

The T Bolt Clamp also facilitates the connection between the turbocharger and the exhaust manifold. This connection must be secure to handle the high temperatures and pressures of the exhaust gases, ensuring that the turbocharger receives the necessary exhaust flow to spin and compress the intake air effectively.

Overall System Integration

By integrating various components such as the air crossover, air tubes, and turbochargers, the T Bolt Clamp contributes to the overall stability and efficiency of the engine system. Its role in securing and mounting these components ensures that the engine operates smoothly, with minimal risk of part failure or performance degradation.

Conclusion

The T Bolt Clamp 3040793 is a vital component in the maintenance and operation of Cummins engines, particularly in heavy-duty truck applications. Its design and functionality ensure secure fastening and stability of critical engine components, contributing to the overall performance and reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the longevity and efficiency of the engine it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.