This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

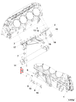

The Cummins 3049216 Tube Clamp is a component designed for use in commercial truck operations. Its purpose is to secure and connect tubing within various automotive systems. A tube clamp generally serves to hold tubing in place, ensuring a secure connection that can withstand the pressures and vibrations encountered in vehicle operations. In commercial trucks, these clamps are vital for maintaining the integrity of fluid transfer systems, including fuel lines, hydraulic systems, and exhaust systems 1.

Basic Concepts of Tube Clamps

Tube clamps operate on the principle of compression to secure tubing. They typically consist of a band that wraps around the tubing and a mechanism to tighten the band, creating a secure fit. The materials used in tube clamps vary but commonly include metals like stainless steel or aluminum for their strength and corrosion resistance, and elastomers for their flexibility and sealing properties 2.

Purpose of the Cummins 3049216 Tube Clamp

The Cummins 3049216 Tube Clamp is specifically designed to play a role in securing tubing within a truck’s systems. It is often associated with fuel lines, hydraulic systems, or exhaust systems, where it ensures that connections remain intact under operational stress. This clamp helps maintain the efficiency and safety of these systems by providing a reliable connection point 3.

Key Features

The Cummins 3049216 Tube Clamp features a design that includes a durable band and a tightening mechanism, typically a screw or lever, to ensure a secure fit. It is composed of materials that offer both strength and flexibility, allowing it to accommodate various tubing sizes and types. Unique attributes may include corrosion-resistant coatings or specialized band designs that enhance grip and durability.

Benefits

Using the Cummins 3049216 Tube Clamp offers several advantages, including improved reliability in tubing connections, which is crucial for the safe operation of a truck. Its design allows for ease of installation, reducing downtime during maintenance. Additionally, the clamp’s durability and resistance to corrosion contribute to lower maintenance requirements and longer component lifespan, enhancing overall truck performance and longevity.

Installation Process

Installing the Cummins 3049216 Tube Clamp involves positioning the band around the tubing, ensuring it is centered and aligned correctly. The tightening mechanism is then used to secure the clamp in place. Best practices include checking for proper alignment before final tightening and ensuring the clamp is snug but not overtightened to avoid damaging the tubing.

Troubleshooting and Maintenance

Common issues with tube clamps may include loosening over time due to vibrations or corrosion. Regular inspections can help identify these issues early. Maintenance practices should include checking the clamp’s condition during routine service intervals, looking for signs of wear or corrosion, and ensuring all connections remain secure. Replacing worn or damaged clamps promptly can help maintain system integrity.

Safety Considerations

When installing or maintaining the Cummins 3049216 Tube Clamp, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, ensuring the truck is securely parked and the engine is off before beginning work. Understanding the potential hazards, such as loose connections leading to fluid leaks or system failures, and taking steps to mitigate them, is crucial for safe operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its commitment to quality and performance in the commercial truck industry. The company’s focus on engineering excellence and customer satisfaction underscores its reputation as a trusted provider of automotive components.

Tube Clamp 3049216 Compatibility with Cummins Engines

The Tube Clamp part number 3049216, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for securing and maintaining the integrity of various tubes and hoses within the engine system.

N14 CELECT and N14 MECHANICAL Engines

For the N14 CELECT and N14 MECHANICAL engines, the Tube Clamp 3049216 is an essential component. It ensures that the cooling system’s hoses and tubes are properly secured, preventing any leaks or disconnections that could lead to engine overheating or other performance issues. Its robust design and high-quality material make it suitable for the demanding conditions these engines operate under.

V903 and VTA903 CM2250 V105 Engines

Similarly, the Tube Clamp 3049216 is compatible with the V903 and VTA903 CM2250 V105 engines. In these engines, the clamp is used to secure various fluid lines, ensuring that the engine’s hydraulic and cooling systems function correctly. The precision engineering of this part guarantees a tight and reliable fit, which is critical for maintaining the performance and longevity of these engines.

By using the Tube Clamp 3049216 across these engine models, Cummins ensures that their customers benefit from a standardized and reliable component that enhances the overall efficiency and safety of their engines.

Role of Part 3049216 Tube Clamp in Engine Systems

The part 3049216 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in maintaining the integrity of fluid pathways within the engine, contributing to overall performance and reliability.

Integration with Cooler Systems

In cooler systems, such as the engine oil cooler and lubricating oil cooler, the Tube Clamp secures the connections between the cooler and the associated piping. This ensures that there are no leaks in the system, which is vital for maintaining the proper flow of coolant and oil. The clamp helps in withstanding the pressure and temperature variations that these fluids experience, thereby enhancing the durability of the cooler system.

Lub Oil Filter and Housing Connections

When connecting the lub oil filter to its housing, the Tube Clamp provides a tight and reliable seal. This is important for preventing oil leaks, which can lead to contamination and reduced efficiency of the lubrication system. The clamp’s ability to adapt to different diameters ensures a custom fit, accommodating various filter and housing designs.

Thermostat and Housing Mounting

In thermostat housing applications, the Tube Clamp secures the connections between the thermostat housing and the water transfer inlet tube. This ensures that the coolant flow is regulated effectively, allowing the engine to reach and maintain optimal operating temperatures. The clamp’s robust design helps in managing the thermal expansion and contraction of the materials involved.

Manifold and Water Systems

Within the manifold and water systems, the Tube Clamp is used to connect various components such as the oil cooler mounting and the oil filter/cooler. It ensures that the pathways for water and oil remain intact, facilitating efficient heat exchange and lubrication. The clamp’s reliability in high-pressure environments is particularly beneficial in these applications.

Overall System Integrity

Across all these applications, the Tube Clamp contributes to the overall integrity of the engine systems by providing a secure and leak-proof connection. Its role in maintaining the structural and functional reliability of these components is indispensable for the smooth operation of the engine.

Conclusion

The Cummins 3049216 Tube Clamp is a critical component in the maintenance and operation of commercial truck engine systems. Its design and functionality ensure secure and reliable connections across various fluid pathways, contributing to the overall performance and longevity of the engine. Regular maintenance and adherence to safety guidelines are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.