This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3062157 Tube Clamp is a specialized component designed for use in commercial truck operations. Its purpose is to secure and maintain the integrity of tubing systems within the truck’s infrastructure. This clamp plays a role in ensuring the safe and efficient operation of various systems, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to hold tubing in place, ensuring a secure and leak-free connection. They are commonly employed in automotive and industrial applications to join pipes and tubes, providing a robust and adjustable means of attachment. Tube clamps function by compressing the tubing against a fixed surface, creating a tight seal that prevents fluid or gas leakage. Their versatility and ease of use make them indispensable in various systems where secure tubing connections are required 1.

Purpose of the Cummins 3062157 Tube Clamp

The Cummins 3062157 Tube Clamp is specifically designed to secure and maintain the integrity of tubing systems in commercial trucks. It plays a role in ensuring that the connections within these systems remain tight and secure, which is vital for the proper functioning of the truck. By providing a reliable method for attaching and securing tubing, this clamp helps to prevent leaks and ensure that fluids or gases are transported efficiently throughout the vehicle’s systems 2.

Key Features

The Cummins 3062157 Tube Clamp boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes adjustable bands that allow for a secure fit on various tubing sizes, providing flexibility and ease of use. Additionally, the clamp features a robust construction that can withstand the vibrations and stresses encountered in commercial truck operations 3.

Benefits

The Cummins 3062157 Tube Clamp offers several advantages for truck operations. Its secure clamping mechanism improves safety by preventing leaks and ensuring that tubing connections remain intact. The reliability of the clamp contributes to the overall efficiency of the truck’s systems, reducing the likelihood of downtime due to tubing failures. Furthermore, the durability of the clamp ensures long-term performance, providing value and peace of mind to fleet operators 4.

Installation Process

Proper installation of the Cummins 3062157 Tube Clamp is crucial for ensuring its effectiveness. Begin by selecting the appropriate size clamp for the tubing to be secured. Position the clamp around the tubing and adjust the bands to achieve a snug fit. Use the provided tools to tighten the clamp, ensuring that it is secure but not overly tight to avoid damaging the tubing. Verify the connection by checking for leaks and ensuring that the clamp is firmly in place 5.

Troubleshooting and Maintenance

Common issues with tube clamps may include loosening over time or damage due to wear and tear. To diagnose problems, inspect the clamp for signs of corrosion, wear, or improper installation. Regular maintenance involves checking the clamp for tightness and ensuring that it remains securely fastened. If issues are detected, re-tighten the clamp or replace it if necessary to maintain the integrity of the tubing system 6.

Safety Considerations

When working with tube clamps, it is important to observe several safety practices. Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against potential injuries. Handle the clamp carefully to avoid sharp edges or excessive force that could cause damage. Follow manufacturer guidelines for installation and maintenance to ensure safe and effective use of the clamp 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operators.

Tube Clamp 3062157 Compatibility with Cummins Engines

The Tube Clamp part number 3062157, manufactured by Cummins, is designed to fit seamlessly with the following engines:

- N14 CELECT

- N14 MECHANICAL

This tube clamp is engineered to ensure a secure and reliable connection for various fluid lines within these engines. Its design and material composition make it suitable for high-pressure environments, ensuring durability and performance over time. The clamp’s compatibility with both the N14 CELECT and N14 MECHANICAL engines underscores its versatility and importance in maintaining the integrity of the engine’s fluid systems.

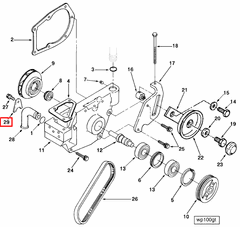

Role of Part 3062157 Tube Clamp in Engine Systems

The 3062157 Tube Clamp is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to secure and stabilize tubing connections, ensuring that fluid transfer within the engine remains consistent and unimpeded.

In the context of the cooler system, the Tube Clamp plays a significant role in securing the connections between the cooler and other components, such as the lubricating mounting cooler. This ensures that the coolant circulates effectively, maintaining optimal engine temperature.

When integrated with the lub oil filter and lubricating mounting cooler, the Tube Clamp helps in maintaining a secure connection, which is vital for the efficient filtration and cooling of the lubricating oil. This, in turn, enhances the longevity and performance of the engine components.

In systems involving the oil filter / cooler, the Tube Clamp ensures that the connections between the oil filter and the cooler are tight and leak-free. This is important for maintaining the quality of the oil and ensuring that the cooling process is effective.

For the pump system, particularly the water pump, the Tube Clamp is used to secure the water transfer tube. This ensures that water is efficiently pumped through the engine, aiding in the cooling process and preventing any potential leaks that could lead to engine damage.

Overall, the 3062157 Tube Clamp is a key component in ensuring that the various fluid transfer systems within an engine operate smoothly and efficiently. Its role in securing and stabilizing tubing connections is fundamental to the overall performance and reliability of the engine.

Conclusion

The Cummins 3062157 Tube Clamp is a vital component in the maintenance and operation of commercial truck engines. Its design and features ensure secure and reliable connections within the engine’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the performance and longevity of this part.

-

Jazar, R. N. (2017). Vehicle Dynamics: Theory and Application. Springer.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSX11.9 CM2250 ECF. Bulletin Number 2883563.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSX11.9 CM2250 ECF. Bulletin Number 2883563.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSX11.9 CM2250 ECF. Bulletin Number 2883563.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.