This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

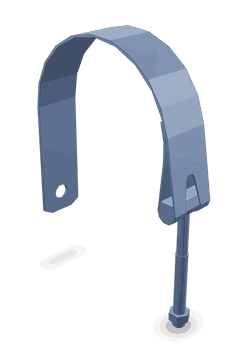

The Cummins 3067807 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for anyone involved in the maintenance or operation of commercial trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a seal that prevents leaks and ensures the integrity of the system. Tube clamps come in various designs and materials, each suited to specific applications based on the type of tubing and the environment in which it operates 1.

Purpose of the Cummins 3067807 Tube Clamp

The Cummins 3067807 Tube Clamp plays a role in securing and connecting tubing within a truck’s systems. Its application spans across various components, ensuring that fluids and gases are transported efficiently and without leakage. This clamp is integral to maintaining the operational integrity of the truck’s systems, contributing to its overall performance and reliability 2.

Key Features

The Cummins 3067807 Tube Clamp is characterized by its robust material composition and design elements that enhance its functionality and durability. It is crafted from materials that resist corrosion and wear, ensuring long-term reliability. The design of the clamp allows for easy installation and adjustment, facilitating maintenance and repair processes 3.

Benefits of Using the Cummins 3067807 Tube Clamp

Utilizing the Cummins 3067807 Tube Clamp offers several advantages. It contributes to improved system integrity by providing a secure and leak-proof connection. The ease of installation reduces downtime during maintenance, and its durable construction ensures long-term reliability, minimizing the need for frequent replacements 4.

Installation Process

Installing the Cummins 3067807 Tube Clamp involves several steps to ensure a secure and effective connection. It begins with properly aligning the tubing and clamp, followed by tightening the clamp to the manufacturer’s specifications. Best practices include checking for proper alignment and ensuring the clamp is not overtightened, which could damage the tubing 5.

Maintenance and Troubleshooting

Maintaining the Cummins 3067807 Tube Clamp involves regular inspection for signs of wear or damage. Common issues include corrosion, leaks, or loosening of the clamp. Addressing these issues promptly can prevent more significant problems and ensure the continued reliability of the truck’s systems 6.

Compatibility and Applications

The Cummins 3067807 Tube Clamp is designed for use in specific truck models and systems. Its compatibility ensures that it fits securely and functions effectively within the intended applications. Understanding its applications helps in selecting the appropriate clamp for maintenance or repair tasks 7.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3067807 Tube Clamp, it is important to observe safety guidelines and precautions. This includes ensuring the truck is properly secured and the engine is off during installation or maintenance. Wearing appropriate personal protective equipment (PPE) is also recommended to protect against potential hazards 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the commercial truck industry. The Cummins 3067807 Tube Clamp is a testament to the company’s commitment to quality and durability in its product offerings 9.

Role of Part 3067807 Tube Clamp in Engine Systems

The 3067807 Tube Clamp is an essential component in securing and maintaining the integrity of various fluid pathways within engine systems. Its application is particularly significant in the following components:

Lubrication Oil Filter

In the lubrication oil filter system, the 3067807 Tube Clamp ensures a secure connection between the filter housing and the associated tubing. This connection is vital for maintaining the flow of lubricant, which is necessary for reducing friction and wear on moving parts within the engine 10.

Lubrication Oil Cooler

When integrated with the lubrication oil cooler, the 3067807 Tube Clamp plays a key role in maintaining the structural stability of the cooler’s inlet and outlet tubes. This stability is important for efficient heat exchange, which helps in maintaining optimal oil temperature and viscosity, thereby enhancing engine performance and longevity 11.

Oil Cooler

In oil cooler applications, the 3067807 Tube Clamp facilitates a reliable connection between the cooler and the oil lines. This ensures consistent and efficient cooling of the oil, which is essential for dissipating excess heat generated during engine operation. Proper cooling prevents thermal degradation of the oil and maintains its lubricating properties 12.

Oil Filter / Cooler

For systems that combine oil filtration and cooling functions, the 3067807 Tube Clamp is instrumental in securing the connections to both the filter and cooler components. This dual-function setup relies on the clamp to ensure that both filtration and cooling processes occur without interruption, contributing to overall engine efficiency and reliability 13.

Cooler

In general cooler applications, whether for oil, transmission fluid, or other engine fluids, the 3067807 Tube Clamp ensures that the tubing connections remain intact under varying operational conditions. This reliability is important for maintaining the cooler’s effectiveness in dissipating heat, which is crucial for the proper functioning of the engine system 14.

Conclusion

The Cummins 3067807 Tube Clamp is a vital component in the maintenance and operation of commercial trucks, ensuring the integrity and efficiency of various engine systems. Its robust design, ease of installation, and durable construction make it a reliable choice for securing and connecting tubing within these systems. Regular maintenance and adherence to safety guidelines are essential for maximizing the performance and longevity of this part.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579937). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.