This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

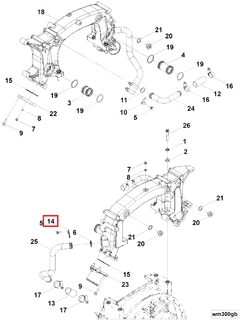

Introduction

The Cummins 3069843 Tube Clamp is a component designed for use in commercial trucks. It serves to secure and connect tubing systems, ensuring the integrity and efficiency of various truck systems. Understanding its purpose and significance is important for maintaining the operational effectiveness of commercial vehicles.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold and connect tubing in automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a secure and leak-proof connection. This mechanism is vital for systems where fluid or gas transfer is necessary, ensuring that connections remain tight under varying conditions 1.

Purpose of the Cummins 3069843 Tube Clamp

The Cummins 3069843 Tube Clamp plays a specific role in the operation of commercial trucks by securing tubing in various systems. Its application includes fuel lines, coolant systems, and other fluid transfer applications. By providing a reliable connection, it helps maintain the efficiency and safety of these systems 2.

Key Features

The Cummins 3069843 Tube Clamp is characterized by several key features that enhance its performance and durability. These include a robust material composition, typically made from high-strength materials to withstand the pressures and temperatures of commercial truck systems. Its design elements, such as the clamping mechanism, are engineered to provide a secure fit without damaging the tubing. Additionally, any unique characteristics, such as corrosion resistance or ease of installation features, contribute to its effectiveness 3.

Benefits

The Cummins 3069843 Tube Clamp offers several benefits, including improved system integrity through secure connections that prevent leaks. Its design allows for ease of installation, reducing downtime during maintenance. Furthermore, the clamp’s durability and resistance to wear contribute to maintenance advantages, making it a reliable component for long-term use.

Installation Process

Installing the Cummins 3069843 Tube Clamp involves several steps to ensure a secure fit. Begin by cleaning the tubing to remove any debris or contaminants. Position the clamp around the tubing and use the appropriate tools to tighten it, ensuring even pressure is applied. Best practices include checking for proper alignment and ensuring the clamp is not overtightened, which could damage the tubing.

Troubleshooting Common Issues

Common problems with tube clamps, such as leaks or loose connections, can often be traced back to installation errors or wear and tear. Troubleshooting steps include inspecting the clamp for signs of damage, ensuring it is properly tightened, and checking the condition of the tubing. Addressing these issues promptly can prevent more significant problems down the line.

Maintenance Tips

Regular maintenance of the Cummins 3069843 Tube Clamp is important for ensuring long-term performance and reliability. This includes periodic inspection for signs of wear or damage, cleaning the clamp and tubing to remove any buildup, and tightening connections as needed. Adhering to recommended inspection intervals and maintenance procedures can extend the life of the clamp and the systems it serves.

Compatibility and Applications

The Cummins 3069843 Tube Clamp is designed for use in specific applications within commercial truck systems. Its compatibility with other components is an important consideration, ensuring that it fits and functions correctly within the intended system. Understanding these applications and compatibility factors is important for effective use and integration into truck maintenance and repair practices.

Safety Considerations

When installing or maintaining the Cummins 3069843 Tube Clamp, observing safety practices and precautions is important. This includes wearing appropriate personal protective equipment, ensuring the truck is safely supported, and following manufacturer guidelines for installation and maintenance. These precautions help prevent accidents and ensure safe operation of the vehicle.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a trusted name in the automotive and heavy-duty truck sectors.

Role of Part 3069843 Tube Clamp in Engine Systems

The part 3069843 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of fluid transfer pathways, which is vital for the overall performance and reliability of the engine.

Cooler Systems

In cooler systems, the Tube Clamp secures the connections between the cooler and the associated fluid lines. This ensures that the coolant or oil being circulated through the cooler maintains a consistent flow without leaks. The clamp’s reliable hold prevents any potential disruptions that could lead to overheating or reduced cooling efficiency.

Torque Converter Oil Systems

For torque converter oil systems, the Tube Clamp plays a significant role in securing the oil lines that supply and return oil to and from the torque converter. This ensures that the oil flow is uninterrupted, which is essential for the smooth operation of the transmission. Proper oil circulation is necessary to maintain the torque converter’s performance and longevity.

Manifold Systems

In manifold systems, the Tube Clamp is used to secure various fluid lines that connect to the manifold. Whether it’s for fuel, coolant, or other fluids, the clamp ensures that these connections remain tight and secure. This is particularly important in high-pressure environments where any leak could result in decreased engine efficiency or potential damage.

Water Systems

For water systems, the Tube Clamp is instrumental in securing the water lines that circulate coolant throughout the engine. This includes connections to the radiator, water pump, and other critical components. A secure connection ensures that the coolant flow is consistent, helping to maintain optimal engine temperature and prevent overheating.

Water Transfer Tube

The Tube Clamp is also vital in securing the water transfer tube, which is responsible for transferring water between different parts of the engine or cooling system. This ensures that water is efficiently circulated, contributing to the engine’s thermal management. The clamp’s role here is to prevent any leaks or disconnections that could impair the cooling process.

Conclusion

The Cummins 3069843 Tube Clamp is a critical component in the maintenance and operation of commercial truck systems. Its role in securing tubing connections across various engine systems ensures the efficiency, reliability, and safety of these vehicles. Understanding its features, benefits, and proper installation and maintenance practices is essential for maximizing its effectiveness and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.