This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3084594 Tube Clamp is a component designed to secure and connect tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems by ensuring that tubing connections remain secure under operational conditions.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place, providing a secure connection without the need for welding or soldering. They are widely utilized in automotive and industrial applications to join tubing systems, allowing for easy assembly, disassembly, and maintenance. Tube clamps function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and maintains the structural integrity of the tubing system 1.

Purpose of the Cummins 3084594 Tube Clamp

The Cummins 3084594 Tube Clamp is specifically designed to play a role in the operation of commercial trucks by securing tubing connections in various systems. Its application ranges from fuel lines to hydraulic systems, ensuring that these components operate efficiently and reliably. By maintaining secure connections, the tube clamp contributes to the overall performance and safety of the truck.

Key Features

The Cummins 3084594 Tube Clamp is constructed with durability and performance in mind. It is made from high-quality materials that resist corrosion and wear, ensuring long-lasting use in demanding environments. The clamping mechanism is designed to provide a strong and consistent grip on the tubing, enhancing the security of the connection. Additionally, the clamp features an easy-to-use design that simplifies installation and removal, making it a practical choice for maintenance and repair tasks.

Benefits of Using the Cummins 3084594 Tube Clamp

Utilizing the Cummins 3084594 Tube Clamp offers several advantages. Its durable construction ensures longevity, reducing the need for frequent replacements. The ease of installation allows for quick assembly and disassembly, facilitating efficient maintenance procedures. Moreover, the reliable clamping mechanism ensures secure tubing connections, contributing to the safe and efficient operation of the truck’s systems.

Installation Process

Installing the Cummins 3084594 Tube Clamp involves several steps to ensure a secure fit. Begin by cleaning the tubing to remove any debris or contaminants that could affect the seal. Position the clamp around the tubing, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, applying even pressure to achieve a consistent grip. Verify the connection by checking for leaks or looseness, making adjustments as necessary to ensure a secure and leak-free connection.

Maintenance and Troubleshooting

To maintain the Cummins 3084594 Tube Clamp, regular inspections are recommended to check for signs of wear, corrosion, or damage. If any issues are detected, such as a loose connection or visible wear on the clamp, it should be addressed promptly to prevent potential failures. Common troubleshooting steps include tightening the clamp if it has become loose, replacing worn or damaged components, and ensuring that the tubing remains clean and free of obstructions.

Compatibility and Applications

The Cummins 3084594 Tube Clamp is versatile, finding applications in a variety of truck systems including fuel lines, hydraulic systems, and more. Its compatibility with different tubing sizes and materials makes it a valuable component for maintaining and repairing commercial trucks. The widespread use of this clamp across various systems underscores its importance in ensuring the reliability and efficiency of truck operations.

Safety Considerations

When installing or maintaining the Cummins 3084594 Tube Clamp, it is important to observe safety guidelines to protect personnel and ensure the integrity of the truck’s systems. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and powered down during maintenance, and following manufacturer recommendations for installation and use. Adhering to these safety practices helps prevent accidents and ensures the reliable operation of the truck.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s extensive product range and commitment to excellence provide context for the quality and reliability of the 3084594 Tube Clamp, reflecting Cummins’ dedication to delivering high-performance components for the automotive and industrial sectors.

Compatibility with Cummins Engines

The Tube Clamp part number 3084594, manufactured by Cummins, is designed to secure and stabilize various tubes and hoses within the engine system. This part is essential for maintaining the integrity of the engine’s cooling and fuel systems by preventing leaks and ensuring that all connections remain tight and secure.

N14 CELECT Engine

In the N14 CELECT engine, the Tube Clamp part 3084594 is used to secure coolant and fuel lines. Given the CELECT system’s advanced electronic controls, it is crucial that all connections are reliable to prevent any disruptions in the engine’s performance. The clamp ensures that the lines remain firmly attached, which is vital for maintaining optimal engine operation.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Tube Clamp part 3084594 serves a similar function, securing coolant and fuel lines. The mechanical nature of this engine variant means that precise and reliable connections are even more critical. The clamp helps in maintaining the structural integrity of the engine’s plumbing, ensuring that there are no leaks or disconnections that could lead to performance issues or engine damage.

Grouping of Engines

Both the N14 CELECT and N14 MECHANICAL engines benefit from the use of the Tube Clamp part 3084594 in similar ways. The primary role of this part is to provide a secure fit for the tubes and hoses, which is essential for the efficient operation of the engine. By ensuring that all connections are tight and secure, the clamp helps maintain the overall reliability and performance of the engine.

Role of Part 3084594 Tube Clamp in Engine Systems

In the context of engine systems, the 3084594 Tube Clamp is instrumental in ensuring the secure and efficient operation of various components.

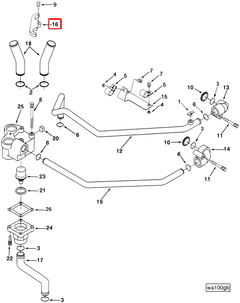

Plumbing Systems

Within the plumbing systems of an engine, the 3084594 Tube Clamp is utilized to maintain the integrity of hose connections. It ensures that fluid lines, which carry essential liquids such as coolant or fuel, remain firmly attached under varying pressure conditions. This clamp helps prevent leaks and maintains consistent fluid flow, which is vital for the engine’s performance and longevity.

Aftercooler Water System

In the aftercooler water system, the 3084594 Tube Clamp plays a significant role in securing the hoses that transport water through the aftercooler. The aftercooler is a component that reduces the temperature of compressed air, enhancing engine efficiency. The clamp ensures that the water lines are tightly sealed, allowing for optimal cooling performance and preventing any water loss that could affect the system’s efficiency.

Thermostat Housing

When integrated with the thermostat housing, the 3084594 Tube Clamp secures the hoses that connect to this housing. The thermostat housing regulates the flow of coolant to the engine, based on its temperature. A secure connection is essential to maintain the correct coolant flow, ensuring the engine operates within its optimal temperature range. This, in turn, helps in preventing overheating and maintains engine efficiency.

Conclusion

The Cummins 3084594 Tube Clamp is a critical component in the maintenance and operation of commercial trucks and engines. Its durable construction, ease of use, and reliable clamping mechanism make it an essential part for securing tubing connections in various systems. By ensuring secure and leak-free connections, this part contributes to the overall performance, safety, and efficiency of truck and engine operations.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.