This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tube Clamp 3092625 by Cummins is a specialized component designed to secure tubing systems in commercial trucks. Its purpose is to ensure the integrity and stability of various tubing connections, which are vital for the proper operation of truck systems. This clamp plays a role in maintaining the efficiency and reliability of truck operations.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in automotive and industrial applications. They operate by compressing the tubing against a saddle or a flat surface, creating a secure and leak-proof connection. Tube clamps are preferred in applications where flexibility, ease of installation, and the ability to accommodate different tubing sizes are required 1.

Purpose of the 3092625 Tube Clamp

The 3092625 Tube Clamp is specifically designed to secure tubing in various truck systems. It is commonly used in applications such as fuel lines, exhaust systems, and hydraulic lines. By providing a reliable connection, this clamp helps maintain the integrity of these systems, ensuring they function correctly and efficiently.

Key Features

The 3092625 Tube Clamp features a robust design that includes a high-strength band and a saddle made from durable materials. Its design allows for easy adjustment and secure fitting, accommodating a range of tubing diameters. The clamp’s material composition ensures resistance to corrosion and wear, enhancing its durability in harsh operating environments.

Benefits

The 3092625 Tube Clamp offers several benefits, including improved system reliability through secure tubing connections. Its design facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, the clamp’s durability and resistance to environmental factors contribute to lower maintenance requirements and extended service life.

Installation Process

Installing the 3092625 Tube Clamp involves several steps to ensure a secure fitting. First, the tubing is positioned on the saddle, and the band is placed over the tubing. Using the appropriate tools, the band is tightened until the desired compression is achieved. It is important to follow best practices, such as ensuring the tubing is properly aligned and the clamp is evenly tightened, to achieve a secure and leak-proof connection.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and loose fittings. To address these problems, it is important to inspect the clamp for proper installation and ensure the tubing is correctly aligned. Tightening the band may resolve loose fittings, while leaks may require re-positioning the tubing or replacing the clamp if damage is detected.

Maintenance Tips

Regular maintenance of the 3092625 Tube Clamp is crucial for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or corrosion, cleaning the clamp and tubing to remove debris, and tightening the band if necessary. Adhering to recommended inspection intervals and maintenance procedures will help prevent issues and ensure the clamp continues to function effectively.

Role in Truck Systems

The 3092625 Tube Clamp integrates within various truck systems, playing a role in maintaining the integrity of fuel lines, exhaust systems, and hydraulic lines. By providing secure and reliable connections, this clamp contributes to the overall performance and efficiency of these systems, ensuring they operate as intended.

Safety Considerations

When working with tube clamps, it is important to follow safety protocols to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the work area is clean and organized, and following manufacturer guidelines for installation and maintenance. Proper handling and use of tools are also critical to ensure the safety of personnel and the integrity of the truck systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to quality and innovation, Cummins serves commercial, industrial, and transportation markets worldwide. The company’s extensive product range and focus on customer satisfaction underscore its position as a leader in the automotive industry 2.

Compatibility with Cummins Engines

The Tube Clamp 3092625, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This part is crucial for maintaining the integrity of the engine’s cooling system by securing tubes and hoses in place. Below is a detailed look at the compatibility of this tube clamp with specific Cummins engines.

QST30 CM552 Engines

The Tube Clamp 3092625 is specifically engineered to fit the QST30 CM552 engines. This engine model is known for its robust performance and reliability, making it a popular choice in various industrial applications. The tube clamp ensures that all coolant and other essential fluids are properly contained within the engine’s system, preventing leaks and maintaining optimal engine performance.

Grouping of Compatible Engines

While the Tube Clamp 3092625 is explicitly designed for the QST30 CM552 engines, it is also compatible with other similar Cummins engine models. These engines share common design features and specifications, allowing the tube clamp to fit securely and effectively. The compatibility extends to engines within the same series or those that have similar configurations and requirements for tube and hose management.

By ensuring that the Tube Clamp 3092625 is used with the appropriate engines, users can maintain the efficiency and longevity of their engine systems. This part plays a role in preventing leaks and ensuring that the engine operates at peak performance.

Role in Engine Systems

The 3092625 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of connections within the fuel system, which is vital for optimal engine performance.

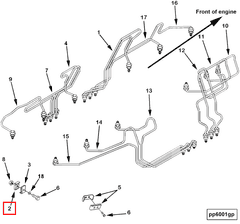

Fuel Supply System

In the fuel supply system, the Tube Clamp secures the injector fuel supply tube. This ensures a consistent and uninterrupted flow of fuel to the injectors. A stable fuel supply is necessary for the injectors to deliver the precise amount of fuel required for combustion, directly influencing engine performance and efficiency.

Vent Tube Connections

The Tube Clamp also plays a significant role in securing vent tubes within the engine system. Vent tubes are responsible for releasing excess pressure and allowing air to enter the fuel tank as fuel is consumed. Proper venting prevents fuel system complications such as vacuum locks, which can impede fuel flow and affect engine operation.

Module and Fuel Control Integration

When integrating the fuel control module with the engine, the Tube Clamp ensures that all connections are tight and secure. This is particularly important in high-performance engines where precise fuel delivery is paramount. The clamp prevents leaks and ensures that the fuel control module can accurately regulate fuel pressure and flow.

Camshaft and Gear Assembly

Although the Tube Clamp is primarily associated with the fuel system, its role extends to other engine components indirectly. For instance, a well-maintained fuel system contributes to the overall performance of the camshaft and gear assembly. Consistent fuel delivery ensures that the engine runs smoothly, reducing wear on the camshaft and related components.

Performance Parts

In the context of performance parts, the Tube Clamp is often overlooked but is equally important. High-performance engines demand components that can withstand greater stresses and deliver consistent performance. The Tube Clamp ensures that all fuel lines remain intact under these demanding conditions, supporting the durability and reliability of performance parts.

Conclusion

The 3092625 Tube Clamp is a foundational element in the engine’s fuel system, contributing to the secure and efficient operation of various components. Its role in maintaining connections within the fuel supply, vent tubes, and fuel control modules is indispensable for achieving optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.