3092628

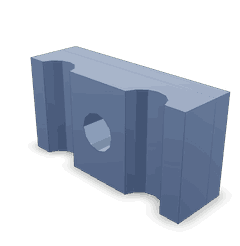

Tube Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3092628 Tube Clamp is a component designed for use in heavy-duty truck maintenance and operation. Its purpose is to secure and connect tubing systems within the truck, ensuring the integrity and efficiency of various fluid and air systems. Understanding its function and significance is vital for maintaining the performance and reliability of heavy-duty trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing in automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the smooth flow of fluids or gases. Tube clamps are essential in systems where flexibility, ease of installation, and secure connections are required 1.

Purpose of the Cummins 3092628 Tube Clamp

This Cummins part plays a role in the operation of a truck by securing tubing in various systems and components. It is applied in systems such as fuel lines, brake lines, and air intake systems, where maintaining a secure and leak-free connection is important for the truck’s performance and safety.

Key Features

The Cummins 3092628 Tube Clamp features a durable material composition, typically made from high-strength steel or aluminum, ensuring resistance to corrosion and wear. Its design includes a band that wraps around the tubing and a screw mechanism that tightens the band, providing a strong and reliable connection. Unique characteristics such as adjustable sizing and ease of installation enhance its performance and durability.

Benefits

The Cummins 3092628 Tube Clamp offers several benefits, including improved system integrity through secure and leak-free connections. Its design allows for easy installation, reducing downtime during maintenance. Additionally, the clamp’s durable construction ensures long-term reliability, contributing to the overall efficiency and safety of the truck’s systems.

Installation Process

To install the Cummins 3092628 Tube Clamp, first, ensure the tubing is clean and free of debris. Position the clamp around the tubing and use the provided screw mechanism to tighten the band until the desired compression is achieved. Tools required may include a wrench or screwdriver, depending on the specific design of the clamp. Following the manufacturer’s guidelines ensures a secure fit and optimal performance.

Troubleshooting Common Issues

Common issues with tube clamps include leaks or loose connections. To address these problems, inspect the clamp for signs of wear or damage. Ensure the clamp is properly tightened and that the tubing is correctly positioned within the clamp. If leaks persist, consider replacing the clamp or inspecting the tubing for damage.

Maintenance Tips

Regular maintenance of the Cummins 3092628 Tube Clamp involves periodic inspection for signs of wear, corrosion, or damage. Cleaning the clamp and tubing can prevent buildup that may affect performance. Replacement should be considered if the clamp shows significant wear or if leaks cannot be resolved through tightening or adjustment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success across automotive, industrial, and power generation sectors 2.

Compatibility with Cummins Engines

The Tube Clamp 3092628, manufactured by Cummins, is a component designed to secure and stabilize various tubes and hoses within the engine’s system. This part is essential for maintaining the integrity and efficiency of the engine’s cooling, fuel, and exhaust systems. Below is a detailed description of how this tube clamp fits with the specified Cummins engines.

QSC8.3 CM850 (CM2850) and QST30 CM2350 T101

The Tube Clamp 3092628 is compatible with both the QSC8.3 CM850 (CM2850) and QST30 CM2350 T101 engines. These engines, while differing in some specifications, share a common design philosophy that emphasizes durability and performance. The tube clamp is used to secure coolant and fuel lines, ensuring that they remain firmly in place under the high pressures and temperatures typical of these engines. Its robust construction helps prevent leaks and maintain the efficiency of the engine’s systems.

QST30 CM552

Similarly, the Tube Clamp 3092628 is also suitable for the QST30 CM552 engine. This engine is part of the same family of Cummins engines, designed to deliver reliable power across various applications. The tube clamp’s role in this engine is to secure and stabilize the tubes and hoses that are integral to the engine’s operation, ensuring that they do not become dislodged or damaged over time. This is particularly important in maintaining the engine’s cooling and fuel systems, which are critical for its performance and longevity.

Application Considerations

When installing the Tube Clamp 3092628 in any of these engines, it is important to ensure that it is properly positioned and tightened to the manufacturer’s specifications. This will help to maintain the integrity of the engine’s systems and prevent any potential issues that could arise from loose or improperly secured tubes and hoses. Regular inspection and maintenance of the tube clamp are also recommended to ensure that it continues to perform its function effectively.

Role of Part 3092628 Tube Clamp in Engine Systems

The 3092628 Tube Clamp is a component in the secure and efficient operation of various engine systems. Its primary function is to ensure a tight and reliable connection between tubes and fittings, which is vital for the proper functioning of the engine.

Fuel System Integration

In the fuel system, the 3092628 Tube Clamp is used to connect the fuel lines to the fuel filter, fuel supply, and fuel drain. This ensures that the fuel flows smoothly and without leaks from the tank to the engine. The clamp’s secure fit prevents any fuel leakage, which could lead to engine performance issues or safety hazards.

Plumbing and Turbocharger Connections

For the plumbing system, the 3092628 Tube Clamp plays a significant role in connecting various plumbing lines, including those associated with the turbocharger. The turbocharger relies on precise and leak-free connections to maintain optimal performance. The tube clamp ensures that the plumbing lines remain intact under high pressure and temperature conditions, contributing to the turbocharger’s efficiency and durability.

Engine Oil Primer and Upfit Kit Applications

In the engine oil primer system, the 3092628 Tube Clamp is used to connect the oil lines, ensuring that the primer system can effectively circulate oil throughout the engine components. This is particularly important during engine start-up, where proper oil circulation is essential to reduce wear and tear.

Additionally, in upfit kits, the tube clamp is utilized to connect various aftermarket components to the engine system. This includes additional fuel lines, plumbing for auxiliary systems, and other modifications that enhance the engine’s functionality or performance. The reliable connection provided by the tube clamp ensures that these upfit components operate seamlessly with the existing engine system.

Conclusion

The Cummins 3092628 Tube Clamp is a vital component in the maintenance and operation of heavy-duty trucks and engines. Its role in securing and connecting tubing systems ensures the integrity and efficiency of various fluid and air systems. Understanding its function, key features, and benefits is essential for maintaining the performance and reliability of heavy-duty trucks and engines. Regular maintenance and proper installation are crucial to ensure the long-term reliability and safety of the systems it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.