This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Clamp 3093597, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces a range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This part is significant in maintaining the integrity of various systems within these trucks, ensuring they operate smoothly and efficiently.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in place. They are commonly employed in automotive applications to hold tubes and hoses, ensuring they remain connected and do not detach under operational conditions. Tube clamps operate by creating a secure grip around the tubing, which is typically achieved through a band that can be tightened using a screw or other mechanism. This grip helps to prevent leaks and ensures that the tubing remains in the correct position, contributing to the overall functionality of the vehicle’s systems 1.

Purpose of the 3093597 Tube Clamp in Truck Operations

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is designed to secure tubes and hoses within the truck’s systems, such as the fuel, coolant, and hydraulic systems. By maintaining a secure connection, the clamp helps to prevent leaks and ensures that fluids are properly directed through the system. This is particularly important in commercial trucks, where the efficient operation of these systems is crucial for the vehicle’s performance and safety.

Key Features of the 3093597 Tube Clamp

The design and construction of this part include several features that enhance its performance and durability. It is made from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The clamp features a robust band that provides a strong grip on the tubing, and its screw mechanism allows for easy adjustment and secure fastening. These features contribute to the clamp’s ability to maintain a reliable connection under various operational conditions 2.

Benefits of Using the 3093597 Tube Clamp

The use of this part offers several advantages in truck systems. It improves safety by ensuring that tubes and hoses remain securely connected, reducing the risk of leaks that could lead to hazardous situations. The clamp also enhances efficiency by maintaining the integrity of the system, ensuring that fluids are properly directed and that the system operates as intended. Additionally, the reliability of the clamp contributes to the overall durability of the truck’s systems, reducing the need for frequent maintenance and repairs.

Installation and Usage Guidelines

To ensure optimal performance, this Cummins part should be installed according to the manufacturer’s guidelines. Begin by selecting the appropriate size clamp for the tubing being secured. Position the clamp around the tubing and use the screw mechanism to tighten it until a secure grip is achieved. It is important to ensure that the clamp is not overtightened, as this could damage the tubing. Regular checks should be performed to ensure that the clamp remains securely fastened and that there are no signs of wear or damage.

Troubleshooting Common Issues

Common problems associated with tube clamps include loosening over time, corrosion, and damage to the tubing. To address these issues, regularly inspect the clamps for signs of wear or corrosion and tighten them as necessary. If a clamp is damaged or shows signs of significant wear, it should be replaced to ensure the continued integrity of the system. Additionally, ensure that the tubing is in good condition and free from damage, as this can affect the performance of the clamp.

Maintenance Tips for Longevity

To extend the lifespan and effectiveness of the 3093597 Tube Clamp, regular maintenance is recommended. This includes periodic inspection of the clamp and tubing for signs of wear, corrosion, or damage. Cleaning the clamp and surrounding area can help prevent the buildup of debris that could affect its performance. Additionally, ensuring that the clamp is properly tightened and adjusted will contribute to its longevity and the overall reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and agriculture. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with several of Cummins’ engine models. It is crucial for ensuring the integrity and functionality of the engine’s cooling system, as it secures and stabilizes the tubes that carry coolant.

QST30 CM2350 T101 and QST30 CM552

This part is compatible with the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of Cummins’ QST30 series, which is known for its robust design and reliability in various industrial applications. The clamp ensures that the coolant tubes remain securely attached, preventing leaks and maintaining optimal engine performance.

Application in Engine Systems

In the QST30 CM2350 T101 and QST30 CM552 engines, this part is integral to the engine’s cooling system. It is used to hold the coolant tubes in place, ensuring that the coolant flows efficiently through the engine. This is essential for maintaining the engine’s temperature within safe operating limits, thereby preventing overheating and potential damage.

Importance of Proper Fitment

Proper fitment of this part is critical for the longevity and efficiency of the engine. Any misalignment or improper installation can lead to coolant leaks, which can cause significant engine damage over time. Cummins has designed this part to ensure a precise fit, making it easy for technicians to install and maintain.

Installation Considerations

When installing this part, it is important to follow the manufacturer’s guidelines to ensure a secure and reliable fit. This includes using the correct torque settings and ensuring that the clamp is properly aligned with the coolant tubes. Regular inspection and maintenance of the clamp can help prevent issues and extend the life of the engine.

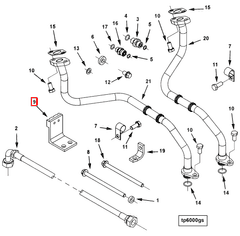

Understanding the Role of Part 3093597 Tube Clamp in Turbocharger Plumbing

In the realm of turbocharger plumbing, this part serves as an essential component that ensures the secure and efficient connection of various hoses and pipes. This clamp is instrumental in maintaining the integrity of the system by providing a reliable seal that prevents leaks and ensures consistent pressure throughout the turbocharger system.

Integration with Turbocharger Components

-

Intercooler Hoses: The Tube Clamp is utilized to connect the intercooler hoses, which are responsible for channeling cooled air from the intercooler to the turbocharger. This connection is vital for maintaining the efficiency of the intercooling process, which in turn enhances the overall performance of the turbocharger.

-

Turbocharger Inlet and Outlet Pipes: Securely fastening the inlet and outlet pipes of the turbocharger is another significant application of the Tube Clamp. This ensures that the airflow into and out of the turbocharger is uninterrupted, which is essential for optimal turbocharger operation.

-

Wastegate Actuator Lines: The Tube Clamp is also employed in the connection of wastegate actuator lines. These lines control the wastegate, which regulates the turbocharger’s boost pressure. A secure connection here is important for precise control over the turbocharger’s performance.

-

Boost Pressure Hoses: In systems where boost pressure needs to be monitored or adjusted, the Tube Clamp is used to connect boost pressure hoses. This ensures that the pressure readings are accurate and that any adjustments made are effectively implemented.

-

Oil Feed and Return Lines: For turbochargers that require oil feed and return lines, the Tube Clamp plays a role in ensuring these connections are leak-free. This is important for the lubrication and cooling of the turbocharger, directly impacting its longevity and performance.

-

Bypass Valve Hoses: In systems equipped with a bypass valve, the Tube Clamp is used to connect the associated hoses. This connection is important for the proper functioning of the bypass valve, which helps in managing the turbocharger’s boost pressure during deceleration.

This part, through its applications in these various connections, contributes to the overall efficiency, reliability, and performance of turbocharger plumbing systems.

Conclusion

The 3093597 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and turbocharger systems. Its design and features ensure secure connections, prevent leaks, and contribute to the overall efficiency and reliability of the systems it is part of. Regular maintenance and proper installation are key to maximizing the benefits of this part and ensuring the longevity of the systems it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.