This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

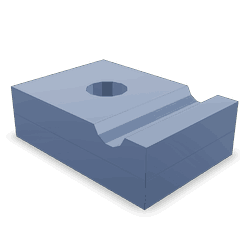

The 3093624 Tube Clamp, manufactured by Cummins, is a component designed to secure tubing systems in commercial trucks. Its purpose is to ensure the integrity and reliability of various fluid and air lines within the truck’s operational systems. Cummins, a well-established manufacturer in the commercial vehicle industry, produces this clamp to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure tubing in automotive and industrial applications. They function by compressing the tubing against a saddle or clamp body, creating a secure connection without the need for welding or soldering. This method allows for easy installation, removal, and adjustment, making tube clamps a versatile solution for securing tubing in various systems 1.

Purpose of Tube Clamp 3093624 in Truck Operations

This Cummins part plays a specific role in the operation of commercial trucks by securing tubing in critical systems such as fuel lines, brake systems, and air conditioning units. Its application ensures that these systems operate efficiently and reliably, contributing to the overall performance and safety of the vehicle.

Key Features of Tube Clamp 3093624

The design and construction of this part include several features that enhance its performance and durability. It is made from high-strength materials to withstand the rigors of commercial truck operations. The clamping mechanism is engineered to provide a secure hold on the tubing, ensuring a leak-free connection. Additionally, the clamp may feature unique attributes such as corrosion resistance and ease of installation, which contribute to its effectiveness in heavy-duty applications 2.

Benefits of Using Tube Clamp 3093624

The use of this part offers several advantages. It provides improved security for tubing connections, reducing the risk of leaks and system failures. The clamp’s design allows for easy installation and removal, facilitating maintenance and repairs. Additionally, its durable construction contributes to long-term reliability, minimizing the need for frequent replacements.

Installation Guidelines

Proper installation of this part involves several steps to ensure optimal performance. Begin by preparing the tubing, ensuring it is clean and free of debris. Align the clamp with the tubing and position it over the saddle or clamp body. Use the appropriate tool to tighten the clamp, ensuring a secure hold without over-tightening, which could damage the tubing.

Maintenance and Troubleshooting

Maintaining this part involves regular inspection to check for signs of wear or damage. Cleaning the clamp and surrounding areas can prevent corrosion and ensure proper function. If issues arise, such as leaks or loose connections, troubleshooting may involve adjusting the clamp or replacing it if necessary. Regular maintenance contributes to the longevity and reliability of the clamp 3.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of heavy-duty applications.

Tube Clamp 3093624 Compatibility with Cummins Engines

This part is a critical component designed to ensure secure and reliable connections in various engine systems. It is engineered to fit seamlessly within the operational framework of several Cummins engines, ensuring optimal performance and durability.

QST30 CM552 Engines

This part is specifically designed to integrate with the QST30 CM552 engines. This compatibility ensures that the clamp provides the necessary support and stability for the engine’s tubing systems, which are crucial for maintaining the integrity of fluid pathways and preventing leaks. The precision engineering of this part guarantees that it will fit perfectly within the design specifications of the QST30 CM552 engines, enhancing the overall reliability and efficiency of the engine.

Grouping of Compatible Engines

While this part is explicitly designed for the QST30 CM552 engines, it is also compatible with a broader range of Cummins engines. This compatibility extends to engines that share similar design parameters and operational requirements, ensuring that the clamp can be used across multiple models without compromising performance. The versatility of this part makes it a valuable component for maintaining and repairing various Cummins engines, providing a reliable solution for securing tubing systems.

Role of Part 3093624 Tube Clamp in Engine Systems

This part is an essential component in maintaining the integrity and performance of various engine systems. It is specifically designed to secure and stabilize tubing within the engine, ensuring that connections remain tight and secure under the high pressures and temperatures typical of engine operation.

Integration with Engine Components

-

Camshaft and Gear: In systems where the camshaft and gear require lubrication or cooling, the Tube Clamp ensures that the associated tubing remains firmly in place. This stability is vital for consistent oil flow and pressure, which directly impacts the performance and longevity of the camshaft and gear.

-

Injector: For fuel injectors, this part plays a significant role in securing the injector fuel supply tube. This ensures a steady and uninterrupted fuel supply, which is essential for the injector’s precise operation and the engine’s overall performance.

-

Injector Fuel Supply Tube: The clamp’s role here is to maintain a secure connection between the fuel supply lines and the injectors. This is important for preventing fuel leaks and ensuring that the fuel delivery system operates efficiently.

-

Vent Tube: In systems with vent tubes, the Tube Clamp helps maintain the integrity of the venting system. This is important for pressure regulation within the fuel tank or other components, ensuring that the system operates within safe parameters.

Performance and Reliability

The use of this part in these applications enhances the reliability and performance of the engine. By securing tubing in place, it prevents disconnections and leaks, which can lead to performance issues or even engine damage. Additionally, the clamp’s ability to withstand high temperatures and pressures makes it a reliable component in demanding engine environments.

Conclusion

In summary, the 3093624 Tube Clamp is a key component in ensuring the secure and efficient operation of various engine systems, contributing to the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.