3094043

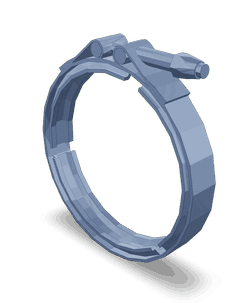

v Band Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3094043 V Band Clamp is a specialized component designed for use in commercial trucks. Its primary role is to secure and seal exhaust and intake systems, ensuring efficient operation and reducing the risk of leaks. This clamp is part of Cummins Inc.’s extensive lineup of automotive and industrial parts, known for their reliability and performance 1.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to connect and seal pipes and ducts in various industrial and automotive applications. They consist of a band that wraps around the pipe and a shell that compresses the band, creating a secure and leak-proof connection. V Band Clamps are favored for their ease of installation, quick release capabilities, and robust sealing properties 2.

Purpose of the Cummins 3094043 V Band Clamp

The Cummins 3094043 V Band Clamp plays a significant role in the operation of commercial trucks by securing and sealing the exhaust and intake systems. This ensures that the systems operate efficiently, minimizing the risk of leaks that could lead to performance issues or safety hazards. The clamp’s design allows for a tight seal, which is crucial for maintaining the integrity of the exhaust and intake pathways 3.

Key Features

The Cummins 3094043 V Band Clamp boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes a band and shell mechanism that provides a strong and consistent clamping force. Additionally, the clamp features easy-to-use levers for quick installation and removal, making it a practical choice for maintenance and repair tasks.

Benefits

The Cummins 3094043 V Band Clamp offers several benefits, including improved sealing efficiency, which helps maintain system performance and reduce the likelihood of leaks. Its ease of installation is another significant advantage, allowing for quick and straightforward setup without the need for complex tools. The clamp’s durability ensures long-term reliability, and its design facilitates easy maintenance, contributing to the overall efficiency of truck operations.

Installation Process

Installing the Cummins 3094043 V Band Clamp involves several steps to ensure optimal performance. Begin by aligning the clamp with the pipe or duct to be connected. Use the provided levers to tighten the band around the pipe, ensuring a secure fit. It is important to follow the manufacturer’s guidelines for torque settings to achieve the correct clamping force. Proper installation is crucial for maintaining the seal and ensuring the system operates efficiently.

Troubleshooting Common Issues

Common issues with V Band Clamps include leaks or improper sealing. To address these problems, first, ensure that the clamp is correctly installed and tightened to the recommended specifications. Inspect the band and shell for any signs of damage or wear that could affect performance. If leaks persist, consider replacing the gasket or the entire clamp to restore a secure seal.

Maintenance Tips

Regular maintenance of the Cummins 3094043 V Band Clamp is important for ensuring longevity and reliable performance. Inspect the clamp periodically for signs of wear or damage, and clean it as necessary to remove any debris that could affect its operation. Following the manufacturer’s recommended inspection intervals will help identify potential issues before they become significant problems, ensuring the clamp continues to perform effectively.

Compatibility and Applications

The Cummins 3094043 V Band Clamp is designed for use in commercial truck systems, where it plays a vital role in securing and sealing exhaust and intake pathways. Its compatibility with various pipe and duct sizes makes it a versatile component for different truck models and applications. When selecting a V Band Clamp, it is important to consider the specific requirements of the system to ensure proper fit and function.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the automotive and industrial sectors. The company’s extensive product lineup includes a wide range of components designed to enhance the performance and reliability of vehicles and equipment.

V Band Clamp 3094043 Compatibility with Cummins Engines

The V Band Clamp 3094043, manufactured by Cummins, is a versatile component designed to fit a range of Cummins engines. This clamp is engineered to provide a secure and leak-proof seal in various applications, making it a critical part for maintaining engine integrity and performance.

GTA38 G CMEICS G116C

The GTA38 G CMEICS G116C engine benefits from the V Band Clamp 3094043 in applications where a reliable sealing solution is required. This clamp ensures that connections remain tight and secure, preventing any leaks that could compromise engine efficiency.

KTA19GC, KTA19GC CM558

For the KTA19GC and KTA19GC CM558 engines, the V Band Clamp 3094043 is essential in maintaining the integrity of various connections. Its design allows for easy installation and removal, making it a practical choice for both routine maintenance and emergency repairs.

M11 MECHANICAL

In the M11 MECHANICAL engine, the V Band Clamp 3094043 is used to secure components that require a robust sealing mechanism. This clamp’s ability to withstand high pressures and temperatures makes it ideal for this engine’s demanding conditions.

QSC8.3 CM850 (CM2850), QSM11 CM570, QST30 CM552

The QSC8.3 CM850 (CM2850), QSM11 CM570, and QST30 CM552 engines also rely on the V Band Clamp 3094043 for critical sealing applications. This clamp’s precision engineering ensures that these engines operate at peak performance by maintaining the necessary seals and preventing any potential leaks.

Role of Part 3094043 V Band Clamp in Engine Systems

The part 3094043 V Band Clamp is instrumental in ensuring secure and efficient connections within various engine components. It is particularly significant in the following applications:

-

Aftercooler: The V Band Clamp is used to connect the aftercooler to the air intake system, ensuring a leak-free seal that maintains the efficiency of the cooling process.

-

Air Crossover Tube Mounting: It plays a key role in mounting the air crossover tube, providing a robust connection that withstands the pressures and vibrations inherent in engine operation.

-

Turbocharger Arrangement: In turbocharger setups, the V Band Clamp is employed to connect the turbocharger to the exhaust and intake systems, facilitating smooth airflow and enhancing performance.

-

Air Crossover Connection: It ensures a secure connection between the air crossover and other components, critical for balanced air distribution in multi-cylinder engines.

-

Air Transfer Connection: The clamp is used in air transfer systems to maintain airtight seals, which is essential for optimal engine performance and efficiency.

-

Exhaust Outlet Connection: It provides a reliable connection at the exhaust outlet, ensuring that exhaust gases are efficiently directed away from the engine compartment.

Conclusion

The Cummins 3094043 V Band Clamp is a critical component in the efficient operation of commercial truck engines. Its robust design, ease of installation, and reliable sealing properties make it an essential part for maintaining the integrity of exhaust and intake systems. Regular maintenance and proper installation are key to ensuring the longevity and performance of this Cummins part.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.