This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

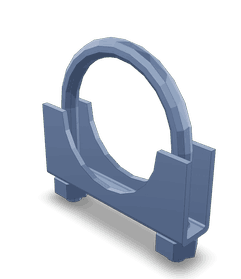

The Cummins 3395439 U-Bolt Clamp is a specialized fastening component designed for use in commercial trucks. Its primary purpose is to secure various components within the truck’s structure, ensuring stability and safety during operation. This clamp is particularly valued in the trucking industry for its reliability and efficiency in fastening applications.

Basic Concepts of U-Bolt Clamps

A U-Bolt Clamp is a type of fastener that consists of a U-shaped bolt with threaded ends. It is used to secure components by passing through holes in the components and then being tightened with nuts. This design allows for a strong and stable connection, crucial for the safe operation of heavy-duty vehicles. In the context of a truck’s structure, U-Bolt Clamps are often used to attach components such as exhaust systems, fuel tanks, and other critical parts that require secure mounting 1.

Role of the 3395439 U-Bolt Clamp in Truck Operation

The 3395439 U-Bolt Clamp plays a specific role in the operation of a truck by securing components that are subject to vibration and movement. It is commonly applied to attach exhaust systems, ensuring they remain firmly in place despite the dynamic conditions of truck operation. Additionally, it is used in securing fuel tanks and other underbody components, contributing to the overall structural integrity and safety of the vehicle.

Key Features of the 3395439 U-Bolt Clamp

The design and material characteristics of the 3395439 U-Bolt Clamp contribute to its effectiveness. Crafted from high-strength materials, it offers durability and resistance to environmental factors such as corrosion and wear. Its design ensures a tight and secure fit, minimizing the risk of component loosening over time.

Benefits of Using the 3395439 U-Bolt Clamp

Utilizing the 3395439 U-Bolt Clamp provides several advantages. It enhances the security of components by offering a robust fastening solution. Its design facilitates ease of installation, reducing downtime during maintenance. Furthermore, the clamp’s durability and resistance to environmental factors contribute to its long-term reliability, making it a cost-effective solution for commercial truck operators.

Installation Process

Installing the 3395439 U-Bolt Clamp requires careful attention to ensure a secure fit. The process involves positioning the U-Bolt through the designated holes in the components to be secured. Nuts are then attached to each end of the bolt and tightened to the specified torque using appropriate tools. It is important to follow best practices, such as using a torque wrench to ensure the clamp is tightened to the manufacturer’s specifications, to achieve a secure and lasting connection.

Troubleshooting Common Issues

Common issues with U-Bolt Clamps, such as loosening or corrosion, can affect their performance. Regular inspections can help identify these problems early. If loosening is detected, re-tightening the clamp to the specified torque can resolve the issue. In cases of corrosion, cleaning the affected areas and applying a corrosion-resistant coating can help maintain the clamp’s integrity.

Maintenance Tips

To ensure the continued performance and longevity of the 3395439 U-Bolt Clamp, regular maintenance checks are recommended. Inspecting the clamp for signs of wear, corrosion, or loosening should be part of routine maintenance. Cleaning the clamp and its surrounding areas, along with applying protective coatings where necessary, can help prevent issues and extend the lifespan of the component.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications 2.

U-Bolt Clamp Part 3395439 Compatibility with Cummins Engines

The U-Bolt Clamp part 3395439, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is crucial for securing various components within the engine assembly, ensuring stability and reliability during operation.

B5.9 GAS PLUS CM556 and G5.9 Engines

The U-Bolt Clamp part 3395439 is compatible with the B5.9 GAS PLUS CM556 and G5.9 engines. These engines are part of Cummins’ lineup, known for their robust performance and durability. The U-Bolt Clamp ensures that the engine’s components are securely fastened, preventing any unwanted movement that could lead to mechanical failures.

G8.3 and G855 Engines

Similarly, the U-Bolt Clamp part 3395439 is also suitable for the G8.3 and G855 engines. These engines are designed for heavy-duty applications, requiring a reliable fastening solution to maintain structural integrity under demanding conditions. The U-Bolt Clamp provides the necessary support, ensuring that all parts remain in their intended positions.

By using the U-Bolt Clamp part 3395439, technicians and engineers can ensure that the engines operate smoothly and efficiently, with all components securely fastened. This compatibility across multiple engine models highlights the versatility and reliability of Cummins’ U-Bolt Clamp in maintaining engine integrity.

Role of Part 3395439 U-Bolt Clamp in Engine Systems

The 3395439 U-Bolt Clamp is an essential component in securing various engine system elements, ensuring stability and integrity within the engine assembly. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

Module Integration

In engine modules, the U-Bolt Clamp is used to secure wiring harnesses and sensor connections. This ensures that electrical components remain firmly in place, reducing the risk of disconnections or shorts that could lead to engine malfunctions. The clamp’s design allows for easy adjustment, accommodating various module sizes and configurations.

Fuel Control System

Within the fuel control system, the U-Bolt Clamp is employed to fasten fuel lines and connectors. This is particularly important in high-pressure fuel systems where secure connections are necessary to prevent leaks and maintain consistent fuel delivery. The clamp’s robust construction ensures that it can withstand the pressures and vibrations inherent in fuel systems.

Auxiliary Cooling System

For the auxiliary cooling system, the U-Bolt Clamp is utilized to secure hoses and fittings. This system often includes components like radiators, coolant reservoirs, and temperature sensors. The clamp helps maintain the integrity of these connections, ensuring efficient coolant flow and temperature regulation, which is vital for engine performance and longevity.

Valve Assemblies

In valve assemblies, the U-Bolt Clamp is crucial for securing actuators and control linkages. These assemblies are responsible for regulating the flow of fluids or gases within the engine. A secure connection ensures that valves operate smoothly and respond accurately to control signals, contributing to overall engine efficiency.

Pressure Regulator Attachments

The U-Bolt Clamp also plays a role in pressure regulator attachments. By securing pressure sensors and regulator components, it ensures that pressure readings are accurate and that the regulator can maintain consistent pressure levels within the engine system. This is essential for optimal combustion and engine performance.

Conclusion

The 3395439 U-Bolt Clamp is a versatile and reliable component that enhances the stability and integrity of various engine systems. Its compatibility with multiple Cummins engine models and its role in securing critical components make it an indispensable part of engine maintenance and operation. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.