This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

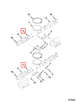

The Cummins 3421896 V Band Clamp is a critical component in commercial truck maintenance and operation, designed to enhance the efficiency and reliability of trucks by securing connections within the exhaust and intake systems 1.

Basic Concepts of V Band Clamps

V Band Clamps are mechanical fasteners used to connect pipes and fittings, providing a secure, leak-proof connection that can withstand high pressures and temperatures. They are valued for their ease of installation and removal, making them ideal for applications requiring frequent disassembly 2.

Role of the 3421896 V Band Clamp in Truck Operation

This Cummins part secures connections within the exhaust and intake systems, ensuring a tight seal that prevents leaks and contributes to the overall performance and reliability of the truck 3.

Key Features

The 3421896 V Band Clamp features a stainless steel band and saddle, offering durability and corrosion resistance. Its design provides a uniform clamping force, enhancing the seal’s effectiveness and facilitating easy installation and removal 4.

Benefits of Using the 3421896 V Band Clamp

This part offers an improved seal compared to traditional methods, reducing leak risks. Its design allows for quick connections and disconnections, and its durability and resistance to environmental factors contribute to long-term performance and cost-effectiveness 5.

Installation Process

To install the 3421896 V Band Clamp, ensure the pipe and fitting are clean. Position the saddle, wrap the band around the assembly, and tighten it using appropriate tools to achieve the desired clamping force, following manufacturer’s torque specifications 6.

Troubleshooting Common Issues

Common issues with V Band Clamps include leaks or installation/removal difficulties. Inspect the clamp for proper installation and ensure no damage to the pipe or fitting. Use correct tools and avoid over-tightening. Regular inspection and maintenance can prevent these issues 7.

Maintenance Tips

Regular maintenance involves periodic inspection for wear or damage, cleaning the clamp and connections to prevent buildup, and following manufacturer’s recommendations for inspection intervals and maintenance procedures to prolong the clamp’s lifespan 8.

Cummins: A Brief Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a century-long history, Cummins has a reputation for quality and innovation in the commercial truck industry, offering a range of products designed to meet demanding commercial applications 9.

V Band Clamp 3421896 Compatibility with Cummins Engines

The V Band Clamp 3421896 is designed to fit various Cummins engines, ensuring secure, leak-proof connections. It is compatible with engines like QSV81G, QSV91G, QSW/QSV82, QSW27, QSW36, and QSW73, enhancing their performance and reliability 10.

Role of Part 3421896 V Band Clamp in Engine Systems

The 3421896 V Band Clamp ensures secure and efficient connections within engine systems, including the exhaust system, turbocharger connections, manifold and exhaust manifold assemblies, and turbocharger arrangements, contributing to engine efficiency and performance 11.

Conclusion

The Cummins 3421896 V Band Clamp is a vital component in commercial truck maintenance, offering durability, ease of use, and enhanced engine performance. Its compatibility with various Cummins engines and its role in securing critical connections make it an indispensable part of modern engine design.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Cummins Inc. (n.d.). QSF2.8 CM2880 F114 Service Manual (4383734).

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). QSF2.8 CM2880 F114 Service Manual (4383734).

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). QSF2.8 CM2880 F114 Service Manual (4383734).

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.