This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3520981 Clamping Plate is a component designed for use in commercial trucks, playing a role in ensuring the secure fastening of various engine components. Cummins Inc., a well-regarded manufacturer in the industry, is known for producing reliable and high-performance parts that contribute to the efficiency and durability of commercial vehicles 1.

Basic Concepts of Clamping Plates

A clamping plate is a mechanical component used to hold parts together securely. It operates on the principle of clamping, where pressure is applied to create a tight seal or connection between components. This secure fastening is vital in mechanical assemblies to prevent movement, ensure stability, and maintain the integrity of the system. Proper clamping helps in distributing loads evenly and reducing the risk of component failure due to vibrations or other dynamic forces 2.

Purpose of the 3520981 Clamping Plate

The 3520981 Clamping Plate is specifically designed to play a role in the operation of commercial trucks by securing certain engine components. Its function contributes to the overall efficiency and reliability of the truck’s engine system. By ensuring that parts remain firmly in place, it helps maintain optimal performance and reduces the likelihood of mechanical issues arising from loose components.

Key Features

The 3520981 Clamping Plate is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features such as precise machining for a perfect fit, robust construction to handle high loads, and possibly unique characteristics like anti-corrosive coatings to enhance performance in various environments. These features collectively contribute to its effectiveness and longevity in demanding applications 3.

Benefits

Using the 3520981 Clamping Plate offers several advantages. Its durable construction leads to improved longevity, reducing the frequency of replacements. Enhanced performance is achieved through secure fastening, which helps maintain engine efficiency. Additionally, the reliability of the clamping plate can lead to potential cost savings over time by minimizing downtime and repair costs associated with component failure.

Installation Process

Proper installation of the 3520981 Clamping Plate is important for ensuring optimal performance and longevity. The installation process involves several steps, including preparing the surface for attachment, aligning the plate correctly, and applying the necessary torque to achieve the proper clamping force. Following these steps ensures that the plate functions as intended, providing a secure and stable connection between components.

Troubleshooting Common Issues

Common problems associated with clamping plates can include loosening over time, corrosion, or damage from wear. Troubleshooting these issues involves inspecting the plate for signs of wear or corrosion, ensuring it is properly tightened, and replacing it if any damage is detected. Regular checks can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To prolong the life of the 3520981 Clamping Plate, regular maintenance practices are recommended. This includes periodic inspections for signs of wear, corrosion, or loosening. Cleaning the plate and its surrounding areas can prevent the buildup of debris that might affect its performance. Replacement should be considered if any significant wear or damage is observed, ensuring the continued reliability of the truck’s engine system.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance parts, Cummins has established itself as a trusted name in the field. Their product range includes a variety of components designed to enhance the efficiency, durability, and performance of commercial vehicles. Cummins’ dedication to excellence is reflected in their continued investment in research and development, ensuring their parts meet the evolving needs of the industry.

Cummins Engine Compatibility with Part 3520981

The Cummins Clamping Plate part number 3520981 is designed to fit seamlessly within various Cummins engine models. This part is engineered to ensure proper assembly and function across a range of engine types.

K19 Engines

The K19 engine series benefits from the precision engineering of the 3520981 Clamping Plate. This part is specifically designed to fit the K19 engine, ensuring that it maintains the structural integrity and operational efficiency of the engine.

N14 Engines

The N14 engine, available in both CELECT and MECHANICAL variants, is another beneficiary of the 3520981 Clamping Plate. This part is crucial for the assembly of both the N14 CELECT and N14 MECHANICAL engines, providing the necessary support and alignment for optimal performance.

NH/NT 855 Engines

The NH/NT 855 engine series also integrates the 3520981 Clamping Plate into its design. This part is tailored to fit these engines, ensuring that they operate smoothly and efficiently.

QSK38 Engines

The QSK38 CM850 MCRS engine is another model that utilizes the 3520981 Clamping Plate. This part is essential for the assembly and functionality of the QSK38 engine, providing the necessary support and alignment for its operation.

Each of these engines relies on the 3520981 Clamping Plate to ensure that they function correctly and efficiently. This part is a testament to Cummins’ commitment to quality and reliability in engine components.

Role of Part 3520981 Clamping Plate in Engine Systems

The 3520981 Clamping Plate is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in the assembly and functionality of several key components.

Integration with Cam Follower Housing and Camshaft

The Clamping Plate is utilized in conjunction with the Cam Follower Housing to maintain the precise alignment and secure positioning of the Camshaft. This ensures that the Camshaft operates smoothly within the Cylinder Head, contributing to the overall efficiency of the valve timing mechanism.

Application in Camshaft Right Bank

In engines with a Camshaft Right Bank configuration, the Clamping Plate is employed to hold the Camshaft in place. This is vital for maintaining the integrity of the valve operation on the right side of the engine, ensuring consistent performance and reliability.

Connection with Connecting Rod and Piston

While the Clamping Plate does not directly interact with the Connecting Rod and Piston, its role in securing the Camshaft and Cylinder Head indirectly supports the smooth operation of these components. A stable Camshaft ensures that the valve timing is accurate, which in turn supports the efficient movement of the Piston within the cylinder.

Use in Control Kit and Core Assembly

In Control Kits and Core Assemblies, the Clamping Plate is often used to secure various components in place. This includes ensuring that the EBM-Injector and EBM-Performance Parts are correctly positioned and operate as intended. The secure fitting provided by the Clamping Plate is essential for the reliable performance of these high-precision components.

Support for Cylinder Head and Dataplate

The Clamping Plate assists in the secure mounting of the Cylinder Head to the engine block. Additionally, it helps in the proper placement of the Dataplate, ensuring that all critical information about the engine’s specifications and performance is accurately recorded and accessible.

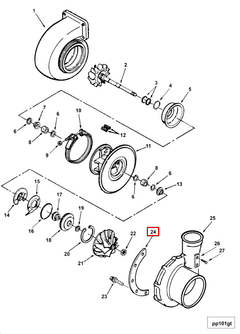

Interaction with EBM-Turbocharger and Performance Parts

When dealing with EBM-Turbocharger systems and other Performance Parts, the Clamping Plate ensures that these components are firmly held in place. This is particularly important for the Heat3B Turbocharger and other high-performance turbo systems, where secure mounting is essential for optimal performance and durability.

Role in Engine Brake Control and Turbocharger Housing Repair Kit

In systems equipped with Engine Brake Control and Turbocharger Housing Repair Kits, the Clamping Plate plays a part in maintaining the structural integrity of these components. It ensures that all parts are correctly aligned and secured, which is essential for the safe and efficient operation of the turbocharger and brake control systems.

Contribution to Supercore and H3B Turbo Systems

For Supercore and H3B Turbo systems, the Clamping Plate is used to ensure that all components, including the Turbocharger Kit and Turbocharger Housing, are securely fitted. This is crucial for maintaining the high-performance standards expected from these advanced engine systems.

Support for Injector Plumbing and Overall Performance

Finally, the Clamping Plate supports the secure fitting of Injector Plumbing and other Performance Parts. This ensures that fuel delivery and other critical systems operate efficiently, contributing to the overall performance and reliability of the engine.

Conclusion

The 3520981 Clamping Plate is a vital component in the operation of Cummins engines, ensuring the secure fastening of various engine components. Its durable construction, precise design, and compatibility with multiple engine models make it an essential part for maintaining the efficiency and reliability of commercial trucks. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.