This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

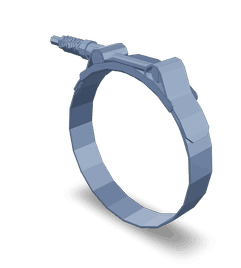

The T Bolt Clamp 3631314, manufactured by Cummins, is a crucial component in the commercial vehicle industry. This clamp is vital for the secure attachment of various components within commercial trucks, ensuring the integrity of connections and preventing inefficiencies or safety concerns during operation.

Basic Concepts of T Bolt Clamps

T Bolt Clamps are mechanical fasteners designed to secure components in place. They are widely used in mechanical systems to ensure parts remain firmly attached under operational conditions. The T Bolt Clamp functions by applying pressure to the components it secures, achieved through the tightening of a bolt that runs through the center of the clamp 1.

Role of T Bolt Clamp 3631314 in Truck Operation

This Cummins part plays a significant role in the operation of commercial trucks by securing specific components within the vehicle’s systems. It is integral to maintaining the integrity of connections, ensuring that parts do not become dislodged during operation, which could lead to inefficiencies or safety concerns 2.

Key Features of T Bolt Clamp 3631314

The T Bolt Clamp 3631314 is characterized by its robust design and material composition, which contribute to its functionality and durability. The clamp is constructed from materials that offer resistance to corrosion and wear, ensuring long-term performance in demanding environments. Its design allows for easy installation and adjustment, facilitating secure component attachment 3.

Benefits of Using T Bolt Clamp 3631314

Utilizing this part offers several advantages. It provides enhanced security for components, reducing the risk of detachment during operation. The clamp’s design allows for straightforward installation, minimizing downtime. Additionally, its durable construction contributes to reduced maintenance requirements, offering cost-effective operation over time.

Installation Process

Installing the T Bolt Clamp 3631314 involves positioning the clamp over the components to be secured, aligning the bolt through the center, and tightening it to the appropriate torque specification. This process may require the use of specific tools to ensure proper installation and to avoid over-tightening, which could damage the components or the clamp itself.

Maintenance Tips

To ensure the longevity and reliable performance of the T Bolt Clamp 3631314, regular inspections should be conducted. These inspections should look for signs of wear, corrosion, or damage. Any issues identified should be addressed promptly to prevent component failure or safety hazards.

Troubleshooting Common Issues

Common problems associated with T Bolt Clamps may include loosening over time, corrosion, or damage to the clamp or components. These issues can often be resolved by re-tightening the clamp, cleaning and treating corroded areas, or replacing damaged components as necessary.

Safety Considerations

When installing, maintaining, or repairing the T Bolt Clamp 3631314, it is important to observe safety practices to prevent accidents or injuries. This includes using the appropriate tools, following torque specifications, and ensuring that all components are securely fastened before operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial vehicle industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

Cummins T Bolt Clamp 3631314 Compatibility

The Cummins T Bolt Clamp 3631314 is a versatile component designed to fit a range of Cummins engines, ensuring secure fastening and stability in various applications.

G5.9 and GTA38 G CMEICS G116C

The 3631314 T Bolt Clamp is compatible with the G5.9 and GTA38 G CMEICS G116C engines. This compatibility ensures that the clamp can be used in these engines to secure various components, maintaining the integrity and performance of the engine systems.

ISB6.7 G CM2180 B118

For the ISB6.7 G CM2180 B118 engine, the 3631314 T Bolt Clamp is engineered to fit seamlessly. This ensures that the clamp can be used to secure parts within the engine, providing the necessary stability and support.

K19, K38, and K50

The 3631314 T Bolt Clamp is also suitable for the K19, K38, and K50 engines. These engines benefit from the clamp’s ability to secure various components, ensuring that the engine operates smoothly and efficiently.

QSK95 CM2350 K111 and QSK95 CM2350 K113

Lastly, the 3631314 T Bolt Clamp is compatible with the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. This compatibility allows the clamp to be used in these engines to secure parts, contributing to the overall performance and reliability of the engine systems.

Role of Part 3631314 T Bolt Clamp in Engine Systems

The T Bolt Clamp, identified by part number 3631314, is a vital component in securing various connections within engine systems. Its application ensures the integrity and efficiency of several key components and their arrangements.

Air Intake and Cleaner Connections

In the air intake system, the T Bolt Clamp is utilized to secure the connection between the air cleaner and the intake manifold. This ensures a sealed passage for air entering the engine, which is vital for maintaining the correct air-fuel ratio. Additionally, it stabilizes the air cleaner housing, preventing any displacement that could lead to air leaks.

Crankcase Breather Arrangement

For the crankcase breather system, the T Bolt Clamp plays a role in maintaining the seal at the connection points. This is important for managing crankcase pressure and ensuring that any gases released are directed properly, either back into the intake system or to an external vent.

Fuel Governor and Cleaner Connections

When it comes to the fuel governor, the T Bolt Clamp is employed to secure the connections that link the governor to the fuel lines. This ensures that fuel delivery is consistent and free from leaks, which is essential for engine performance and efficiency.

Water Outlet and Heat Exchanger Connections

In the engine cooling system, the T Bolt Clamp is critical for securing the water outlet connection to the heat exchanger. This connection is part of the plumbing that circulates coolant through the engine and radiator. The clamp ensures that there are no leaks in the system, which could lead to overheating and engine damage.

Radiator and Thermostat Housing

The T Bolt Clamp is also used in the arrangement of the radiator and thermostat housing. It secures the water outlet connection to the thermostat housing, ensuring that coolant flow is maintained without any interruptions. This is important for the consistent operation of the thermostat and the overall cooling efficiency of the engine.

Heat Exchanger and Mounting Connections

Finally, the T Bolt Clamp is integral in the mounting of the heat exchanger to the engine. It secures the connections of the water tubes to the heat exchanger, ensuring that the transfer of heat from the engine to the coolant is efficient and that there are no leaks in the system.

Conclusion

Overall, the T Bolt Clamp (part 3631314) is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure and leak-free connections. Its robust design, compatibility with a range of Cummins engines, and critical role in maintaining the integrity of engine systems make it an indispensable part in the operation of commercial trucks.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.