This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

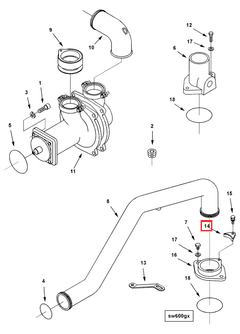

The Cummins 3631783 Tube Clamp is a component designed to secure and connect tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems. Cummins Inc., the manufacturer, is renowned in the industry for its commitment to quality and innovation, providing reliable solutions for automotive and industrial applications 3.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold and connect tubing in various systems. They are commonly employed in automotive and industrial settings to ensure secure connections that can withstand pressure and environmental conditions. Tube clamps function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the smooth flow of fluids or gases 1.

Purpose of the Cummins 3631783 Tube Clamp

The Cummins 3631783 Tube Clamp is specifically designed to play a role in the operation of commercial trucks by securing tubing connections. It is typically associated with systems that require reliable and durable tubing connections, such as fuel lines, hydraulic systems, and cooling systems. The clamp ensures that these connections remain intact under various operating conditions, contributing to the overall efficiency and safety of the truck 2.

Key Features

The Cummins 3631783 Tube Clamp boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes elements that allow for easy installation and adjustment, while also providing a secure fit. Unique characteristics such as reinforced edges and precise engineering contribute to its reliability in demanding applications.

Benefits of Using the Cummins 3631783 Tube Clamp

Incorporating the Cummins 3631783 Tube Clamp into truck maintenance and repair offers several advantages. It provides improved reliability by ensuring secure tubing connections, which can reduce the risk of leaks and system failures. The ease of installation allows for quick repairs and maintenance, minimizing downtime. Additionally, the durability of the clamp contributes to long-term cost savings by reducing the frequency of replacements and repairs.

Installation Process

Proper installation of the Cummins 3631783 Tube Clamp involves several steps to ensure a secure fit. Begin by cleaning the tubing and clamp surfaces to remove any debris or contaminants. Position the clamp around the tubing, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp gradually, checking for even compression around the tubing. Verify the connection by testing for leaks and ensuring there is no excessive tightness that could damage the tubing.

Troubleshooting Common Issues

Common problems associated with tube clamps include leaks and improper sealing. To address these issues, first, inspect the clamp and tubing for signs of wear or damage. Ensure that the clamp is correctly aligned and tightened to the manufacturer’s specifications. If leaks persist, consider replacing the clamp or tubing as necessary. Regular maintenance and inspections can help identify and resolve issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the Cummins 3631783 Tube Clamp is crucial for ensuring longevity and optimal performance. Inspect the clamp and tubing connections at regular intervals, looking for signs of wear, corrosion, or leaks. Clean the clamp and tubing surfaces as needed to remove dirt and debris. Tighten the clamp if necessary to maintain a secure connection. Following these maintenance tips can help extend the life of the clamp and ensure reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and industrial sectors, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and components like the 3631783 Tube Clamp. Cummins’ history is marked by a dedication to advancing technology and providing reliable solutions for its customers, making it a trusted name in the industry 3.

Tube Clamp 3631783 in Cummins Engines

The Tube Clamp 3631783, manufactured by Cummins, is a critical component in the engine systems of various Cummins engines, including the K38 and K50 series. This part is integral in maintaining the structural integrity and operational efficiency of these engines.

K38 Series

In the K38 engine series, the Tube Clamp 3631783 is utilized to secure and stabilize various tubes and hoses that are essential for the engine’s cooling and lubrication systems. Its precise fit and robust design ensure that these components remain firmly in place, preventing any potential leaks or disconnections that could compromise engine performance.

K50 Series

Similarly, in the K50 engine series, the Tube Clamp 3631783 plays a vital role in securing and aligning the tubes and hoses that are part of the engine’s intricate network. This clamp is designed to withstand the high pressures and temperatures typical of engine environments, ensuring long-term reliability and performance.

Grouping of Engines

Both the K38 and K50 engines benefit from the Tube Clamp 3631783 in similar ways, as it is a fundamental part of their design. The clamp’s ability to maintain the integrity of the engine’s fluid pathways is crucial for the overall functionality and longevity of these engines. Its application across these models highlights the importance of standardized components in ensuring consistent performance and ease of maintenance.

Role of Part 3631783 Tube Clamp in Engine Systems

The 3631783 Tube Clamp is an essential component in the secure and efficient operation of various engine systems. Its primary function is to ensure a tight and reliable connection between tubes and other components, preventing leaks and maintaining system integrity.

Heat Exchanger and Heat Exchanger Mounting

In the heat exchanger system, the 3631783 Tube Clamp is used to connect the tubes that carry coolant or other fluids. This ensures that the heat exchanger operates efficiently by maintaining consistent fluid flow and pressure. The clamp also plays a role in the heat exchanger mounting by securing the tubes to the mounting brackets, which is vital for the structural stability of the heat exchanger.

Manifold and Water Pump

When integrated with the manifold and water pump, the 3631783 Tube Clamp helps in directing the flow of water to various parts of the engine. It ensures that the water pump can effectively circulate coolant through the manifold, which is necessary for maintaining optimal engine temperature. The clamp’s secure fit prevents any potential leaks that could disrupt the cooling process.

Raw Water Pump and Sea Water Pump Mounting

In marine engine systems, the 3631783 Tube Clamp is utilized in the raw water pump and sea water pump mounting. It connects the tubes that transport sea water to the pump, ensuring a reliable supply of cooling water. The clamp’s durability is particularly important in marine environments, where corrosion and saltwater can pose significant challenges.

Seawater Pipe Mount and Tube

For the seawater pipe mount and tube, the 3631783 Tube Clamp provides a robust connection that can withstand the pressures and conditions of seawater. This is essential for the efficient operation of the seawater cooling system, which relies on a consistent and leak-free flow of seawater through the pipes.

Water Transfer and Water Bypass Tube

In systems involving water transfer and water bypass tubes, the 3631783 Tube Clamp ensures that these tubes are securely connected to other components. This is important for maintaining the intended flow paths of water within the engine system, whether for cooling, lubrication, or other purposes. The clamp’s reliable performance helps in preventing disruptions that could affect engine efficiency and longevity.

Conclusion

The Cummins 3631783 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design and features ensure secure, reliable connections that contribute to the overall efficiency and safety of the systems it serves. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.