This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

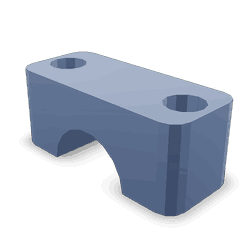

The Tube Clamp 3641298, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part plays a role in the secure connection and maintenance of tubing systems within these trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in both automotive and industrial applications. They function by providing a tight, reliable seal around the tubing, which is important for maintaining the integrity of fluid or gas transport systems. Tube clamps are preferred in many applications due to their ease of installation, adjustability, and the secure connection they provide without the need for welding or soldering.

Purpose of the 3641298 Tube Clamp in Truck Operations

In commercial truck operations, the 3641298 Tube Clamp serves a specific role in securing and connecting various tubing systems. This includes applications in the fuel, hydraulic, and pneumatic systems where secure and leak-free connections are paramount. The clamp ensures that these systems operate efficiently and reliably, contributing to the overall performance and safety of the truck.

Key Features

The 3641298 Tube Clamp is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design of the clamp allows for easy adjustment and secure fitting around the tubing, accommodating a range of diameters. Additionally, the clamp features a robust construction that can withstand the vibrations and stresses typical in truck operations.

Benefits of Using the 3641298 Tube Clamp

Utilizing the 3641298 Tube Clamp in truck maintenance and operation offers several advantages. It provides improved safety by ensuring secure and leak-free connections in critical systems. The reliability of the clamp contributes to the efficiency of truck operations, reducing the likelihood of downtime due to tubing failures. Furthermore, the ease of installation and adjustment of the clamp facilitates quicker maintenance procedures, enhancing overall operational efficiency.

Installation Process

Installing the 3641298 Tube Clamp requires following a series of steps to ensure a secure fit. Begin by cleaning the tubing to remove any debris or contaminants. Position the clamp around the tubing, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, adjusting it until a secure and snug fit is achieved. It is important to follow the manufacturer’s guidelines for torque settings to avoid over-tightening, which could damage the tubing or the clamp itself.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or improper fitting, can often be traced back to incorrect installation or wear and tear. To address leaks, first, ensure the clamp is correctly positioned and tightened. If the problem persists, inspect the tubing for damage or corrosion that may require replacement. For improper fitting, verify that the clamp is compatible with the tubing diameter and that it is installed according to the manufacturer’s instructions.

Maintenance Tips

Regular maintenance checks are recommended to ensure the longevity and optimal performance of the 3641298 Tube Clamp. Inspect the clamp and tubing for signs of wear, corrosion, or damage during routine maintenance intervals. Clean the clamp and surrounding areas to remove any buildup that could affect its performance. If any issues are detected, address them promptly to prevent further complications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction have made it a preferred choice for commercial truck operators worldwide.

Tube Clamp 3641298 Compatibility with Cummins Engines

The Tube Clamp part number 3641298, manufactured by Cummins, is designed to secure and stabilize various tubes and hoses within the engine’s system. This part is compatible with several Cummins engine models, ensuring a secure fit and reliable performance across different engine configurations.

KTA38GC CM558 Series

The Tube Clamp 3641298 is specifically engineered to fit seamlessly within the KTA38GC CM558 series engines. This series is known for its robust design and high performance, making it suitable for demanding applications. The clamp’s precision fit ensures that it maintains the integrity of the engine’s cooling and fuel systems, preventing leaks and ensuring optimal engine operation.

QSK95 CM2350 Series

The QSK95 CM2350 series engines, including the K111 and K113 variants, also benefit from the Tube Clamp 3641298. These engines are widely used in various industries due to their reliability and efficiency. The clamp’s design allows for easy installation and secure attachment of tubes and hoses, which is crucial for maintaining the engine’s performance and longevity.

QSV91-G4 CM558/CM700 V102 Series

The QSV91-G4 CM558/CM700 V102 series engines are another application where the Tube Clamp 3641298 proves its versatility. These engines are known for their versatility and adaptability to different environments and applications. The clamp’s compatibility with these engines ensures that the tubes and hoses remain securely fastened, contributing to the engine’s overall efficiency and reliability.

By ensuring a secure fit across these engine models, the Tube Clamp 3641298 plays a role in maintaining the integrity of the engine’s systems, preventing potential leaks, and ensuring optimal performance.

Role of Part 3641298 Tube Clamp in Engine Systems

The part 3641298 Tube Clamp is a component in various engine systems, ensuring secure and efficient connections across multiple fluid and air pathways.

In the Aid system, the Tube Clamp is utilized to maintain the integrity of connections in the auxiliary systems that support engine operation. This includes securing lines that deliver pressurized fluids or gases to components requiring additional support for optimal performance.

Within the Coolant Heater Starting system, the Tube Clamp plays a role in connecting the heater lines to the engine block or coolant passages. This ensures that the coolant is effectively circulated through the heater core, providing warm air for cabin heating and aiding in engine warm-up during cold starts.

In the Charge Air Bypass Plumbing, the Tube Clamp is employed to secure the bypass lines that allow excess charge air to be redirected. This helps in maintaining consistent pressure levels within the intake system, contributing to stable engine performance under varying load conditions.

For the Filter system, whether it be oil, fuel, or air filters, the Tube Clamp is used to connect the filter housing to the respective lines. This ensures a leak-free seal, preventing contaminants from entering the engine and maintaining filtration efficiency.

In the Fuel system, the Tube Clamp is important for connecting fuel lines from the tank to the engine. It ensures that fuel is delivered under pressure without leaks, which is vital for consistent engine operation and performance.

The Primer system utilizes the Tube Clamp to connect the primer bulb or electric primer to the fuel lines. This facilitates easy bleeding of air from the fuel system, ensuring a smooth start-up process.

In the Engine Lubricating system, the Tube Clamp is used to secure oil lines that deliver lubricant to various engine components. This ensures that all moving parts receive adequate lubrication, reducing friction and wear.

For the Service Kit, the Tube Clamp is often included to replace worn or damaged clamps during maintenance procedures. This ensures that all connections remain secure and leak-free after servicing.

Within the broader System context, the Tube Clamp is a ubiquitous component that ensures the reliability and efficiency of fluid and air pathways. Its role in maintaining secure connections cannot be overstated, as it contributes to the overall performance and longevity of the engine.

In the Auxiliary Cooling system, the Tube Clamp is used to connect additional cooling lines that may be required for high-performance applications or to cool specific engine components. This ensures that all parts of the engine remain within optimal temperature ranges, enhancing performance and reliability.

Conclusion

The 3641298 Tube Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks and various engine systems. Its design and features ensure secure, leak-free connections across multiple fluid and air pathways, contributing to the overall efficiency, safety, and reliability of the vehicle and engine systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring long-term performance and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.