3647803

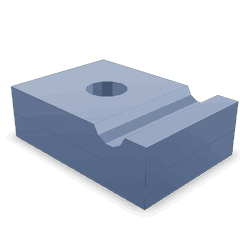

Tube Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3647803 Tube Clamp is a component designed for use in heavy-duty truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps come in different designs and materials, tailored to meet the specific requirements of their applications 1.

Purpose of the Cummins 3647803 Tube Clamp

This Cummins part plays a role in securing and connecting tubing within a truck’s systems. It is applied in various components and systems where tubing is used to transport fluids or gases, ensuring that connections remain secure under operational conditions.

Key Features

The Cummins 3647803 Tube Clamp is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the rigors of heavy-duty truck operation, and its design elements that ensure a secure fit around tubing. Unique characteristics may also include corrosion resistance and ease of installation, contributing to its effectiveness in demanding environments 2.

Benefits of Using the Cummins 3647803 Tube Clamp

Utilizing this part offers several advantages. It contributes to improved system integrity by ensuring secure connections, which is vital for the efficient operation of truck systems. The clamp’s design facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durability and reliability over time make it a cost-effective solution for heavy-duty truck applications 3.

Installation Process

Installing the Cummins 3647803 Tube Clamp involves several steps to ensure a secure fit. The process begins with selecting the appropriate size clamp for the tubing. Tools required may include a screwdriver for adjusting the clamp and a wrench for tightening. Best practices include ensuring the tubing is clean and free of debris before installation and tightening the clamp to the manufacturer’s specified torque to achieve a secure seal without damaging the tubing 4.

Troubleshooting Common Issues

Common issues associated with tube clamps, such as leaks or improper fitting, can often be addressed through systematic troubleshooting. Identifying the source of a leak may involve inspecting the clamp for signs of wear or damage and ensuring it is properly tightened. Improper fitting can sometimes be corrected by readjusting the clamp or replacing it if necessary.

Maintenance Tips

Regular maintenance of the Cummins 3647803 Tube Clamp is important for ensuring its continued performance and longevity. Inspection routines should include checking for signs of wear, corrosion, or damage. Cleaning procedures may involve removing any buildup around the clamp to ensure it operates efficiently. Replacement should be considered if the clamp shows significant wear or if it no longer provides a secure fit.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and industrial sectors. Its product range includes engines, powertrains, and related components, serving a wide array of applications from on-highway to off-highway and industrial uses.

Tube Clamp 3647803 Compatibility with Cummins Engines

The Tube Clamp part number 3647803 is designed to be compatible with several Cummins engine models. This part is essential for securing and maintaining the integrity of various tubes and hoses within the engine system.

QSK50 CM2350 K108

For the QSK50 CM2350 K108 engine, the Tube Clamp 3647803 is used to secure coolant, fuel, and other critical fluid lines. Its robust design ensures that these lines remain tightly fastened, preventing leaks and maintaining the engine’s operational efficiency.

QSK60 CM850 MCRS

Similarly, in the QSK60 CM850 MCRS engine, the Tube Clamp 3647803 plays a crucial role in securing various tubes and hoses. This engine, like the QSK50, relies on this part to maintain the integrity of its fluid systems, ensuring that all connections are secure and leak-free.

Grouped Application

Both the QSK50 CM2350 K108 and QSK60 CM850 MCRS engines benefit from the Tube Clamp 3647803 in similar ways. The clamp’s design allows it to be used across different models, providing a reliable solution for securing tubes and hoses in these Cummins engines. Its application in both engines highlights its versatility and importance in maintaining the overall functionality and safety of the engine systems.

Understanding the Role of Part 3647803 Tube Clamp in Engine Systems

Part 3647803 Tube Clamp is an essential component in the secure and efficient operation of various engine systems. Its application spans across multiple plumbing arrangements, ensuring the integrity and performance of the engine.

Integration with Crankcase Breather System

In the crankcase breather system, the Tube Clamp plays a significant role by securing the hoses that vent crankcase gases. This system is designed to release pressure built up within the crankcase, preventing oil contamination and ensuring the engine operates within optimal parameters. The Tube Clamp ensures a tight and reliable connection, minimizing the risk of leaks and maintaining system efficiency.

Functionality in Fuel Drain Plumbing

Within the fuel drain plumbing, the Tube Clamp is utilized to connect hoses that facilitate the drainage of fuel from the system. This is particularly important during maintenance procedures or in the event of a fuel system malfunction. The secure fitting provided by the Tube Clamp prevents fuel leaks, enhancing safety and ensuring that the fuel system can be drained efficiently without contamination.

Application in Turbocharger Coolant Plumbing

The turbocharger coolant plumbing system relies on the Tube Clamp to connect hoses that circulate coolant through the turbocharger. This system is vital for dissipating heat generated by the turbocharger, prolonging its lifespan and maintaining performance. The Tube Clamp ensures that the coolant hoses are firmly attached, preventing leaks and ensuring consistent coolant flow.

Role in Turbocharger Oil Plumbing

In the turbocharger oil plumbing system, the Tube Clamp is instrumental in securing hoses that supply oil to the turbocharger bearings. Proper lubrication is essential for the turbocharger’s operation, reducing friction and wear. The Tube Clamp’s reliable connection ensures that oil is delivered consistently, supporting the turbocharger’s efficiency and durability.

Importance in Tur Coolant System

The Tur Coolant system, which cools the turbine side of the turbocharger, also benefits from the use of the Tube Clamp. By securing the coolant hoses, the Tube Clamp ensures that coolant is effectively circulated, managing the high temperatures generated during operation. This helps in maintaining the turbocharger’s performance and preventing overheating.

Conclusion

Overall, Part 3647803 Tube Clamp is a versatile component that enhances the reliability and performance of various engine systems through secure and leak-proof connections.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Cummins Inc. Service Manual (5613383). Cummins Inc., 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.