This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3690649 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s tubing systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for mechanics and fleet managers who aim to maintain optimal truck performance.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in both automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps come in various designs and materials, each suited to specific applications based on the environment and the type of tubing used 1.

Purpose of the Cummins 3690649 Tube Clamp

This Cummins part is specifically engineered to play a role in the operation of commercial trucks. It is applied in various truck systems where secure and reliable tubing connections are required. This clamp ensures that the tubing systems remain intact under the demanding conditions encountered in commercial trucking, such as vibrations, temperature fluctuations, and exposure to various elements.

Key Features

The 3690649 is characterized by several key features that enhance its functionality and durability. It is constructed from materials that offer resistance to corrosion and wear, ensuring longevity in harsh operating environments. The design of the clamp includes elements that allow for easy installation and adjustment, facilitating maintenance procedures. Additionally, it may possess unique attributes such as a self-locking mechanism or adjustable bands that provide a secure fit on a range of tubing diameters.

Benefits of Using the Cummins 3690649 Tube Clamp

Utilizing this part offers several advantages. It contributes to improved system integrity by providing a reliable connection that minimizes the risk of leaks. The ease of installation reduces downtime during maintenance, and its durable construction ensures long-term reliability, reducing the frequency of replacements.

Installation Process

Installing the 3690649 requires following a step-by-step process to ensure proper function and safety. Best practices include cleaning the tubing surface before installation, ensuring the clamp is correctly aligned, and tightening it to the manufacturer’s specified torque. Avoiding common pitfalls such as over-tightening, which can damage the tubing, is crucial for a successful installation 2.

Maintenance and Troubleshooting

Regular maintenance of the 3690649 involves inspection routines to check for signs of wear, corrosion, or leaks. Troubleshooting common issues such as leaks or clamp failure may involve tightening the clamp, replacing worn components, or addressing tubing damage. Prompt attention to these issues helps maintain the efficiency and safety of the truck’s systems.

Compatibility and Applications

The 3690649 is designed for use within specific commercial truck systems. Its applications are varied, depending on the truck’s make and model, and it is compatible with a range of tubing types and sizes. Understanding its compatibility with other components or systems is important for ensuring optimal performance and integration within the truck’s overall design.

Safety Considerations

When installing or maintaining the 3690649, observing safety practices and precautions is vital. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and the engine is off during maintenance, and following all manufacturer guidelines to prevent accidents and ensure the safety of mechanics and operators.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck and engine industry. The company’s commitment to excellence is reflected in its products, including the 3690649, which is designed to meet the high standards of commercial trucking operations.

Tube Clamp 3690649 Compatibility with Cummins Engines

The Tube Clamp part number 3690649, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This component is crucial for maintaining the integrity of the engine’s tubing system, ensuring that connections remain secure and leak-free.

QSX15 and CM2350 Engines

The Tube Clamp 3690649 is specifically engineered to integrate with the QSX15 and CM2350 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The clamp’s design ensures a tight seal, preventing any potential fluid leaks that could compromise engine performance.

X105 Engine

Similarly, the X105 engine also benefits from the use of the Tube Clamp 3690649. This engine is part of Cummins’ lineup of high-efficiency, low-emission engines, making it a popular choice for various industrial applications. The clamp’s precision fit is essential for maintaining the engine’s operational standards, ensuring that all tubing connections are secure and durable.

Grouping for Efficiency

When considering the QSX15, CM2350, and X105 engines together, it’s evident that the Tube Clamp 3690649 serves a critical function across these models. Its design allows for easy installation and removal, facilitating maintenance and repairs. This commonality in design underscores Cummins’ commitment to providing high-quality, interchangeable parts that enhance engine longevity and performance.

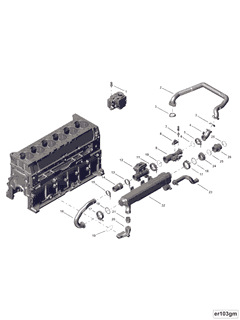

Role of Part 3690649 Tube Clamp in Engine Systems

The part 3690649 Tube Clamp is instrumental in securing and maintaining the integrity of various engine system components. In the context of an Exhaust Gas Recirculation (EGR) system, this tube clamp ensures a tight and reliable seal around the EGR tube. This is essential for the efficient recirculation of exhaust gases back into the intake manifold, which helps in reducing nitrogen oxides (NOx) emissions and improving fuel efficiency.

In an Exhaust Recirculation Air (ERA) arrangement, the tube clamp plays a significant role by securing the connections between the ERA tubes and other components. This ensures that the flow of recirculated air is consistent and unimpeded, contributing to the overall effectiveness of the ERA system in managing exhaust emissions.

Additionally, within the broader arrangement of engine components, the tube clamp aids in maintaining the structural stability of various hoses and tubes. This is particularly important in high-vibration environments typical of engine compartments, where secure connections are paramount to prevent leaks and ensure optimal performance of the engine system 3.

Conclusion

The Cummins 3690649 Tube Clamp is a vital component in the maintenance and operation of commercial trucks, offering reliability, durability, and ease of use. Its role in securing and maintaining the integrity of engine systems is crucial for the efficient operation of commercial vehicles. Understanding its features, benefits, and proper installation and maintenance procedures is essential for mechanics and fleet managers to ensure optimal truck performance and safety.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.