This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

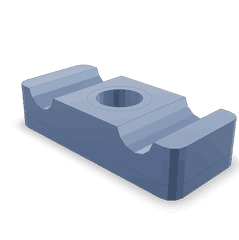

The Cummins 3690650 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is fundamental for maintaining and optimizing commercial truck performance.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps come in various designs and materials, each suited to specific applications based on the environment and the type of tubing used 1.

Purpose of the Cummins 3690650 Tube Clamp

This Cummins part is specifically designed to play a role in the operation of commercial trucks. It is applied in various truck systems where secure and reliable connections of tubing are required. This clamp ensures that the connections remain intact under the demanding conditions typical of commercial truck operation, contributing to the system’s overall performance and durability.

Key Features

The 3690650 features a design that includes high-quality materials and construction elements to enhance its functionality and durability. Its material composition is chosen for resistance to corrosion and wear, ensuring longevity in harsh operating environments. The design elements of the clamp, such as its band and screw mechanism, are engineered to provide a secure and adjustable fit around the tubing, accommodating variations in tubing diameter and ensuring a leak-free connection.

Benefits of Using the Cummins 3690650 Tube Clamp

Utilizing this part offers several advantages. It provides improved reliability in tubing connections, reducing the risk of leaks and ensuring consistent performance. The design of the clamp also facilitates ease of installation, allowing for quick and secure connections without the need for specialized tools. Additionally, its construction supports straightforward maintenance, enabling technicians to inspect and replace the clamp as needed with minimal disruption to the truck’s operation.

Installation Process

Installing the 3690650 involves several steps to ensure a secure fit. First, the tubing should be cleaned and prepared for clamping. The clamp is then positioned around the tubing, and the screw mechanism is tightened to achieve the desired compression. It is important to use the appropriate tools and follow best practices to avoid over-tightening, which could damage the tubing or the clamp itself. Proper installation is key to ensuring the clamp functions as intended.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or improper fitting, can often be traced back to installation errors or wear and tear. Troubleshooting these problems involves inspecting the clamp and tubing for signs of damage or misalignment. Adjusting the clamp or replacing damaged components can resolve most issues, restoring the system’s integrity and performance.

Maintenance Tips

Regular maintenance of the 3690650 is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or corrosion, cleaning the clamp and tubing to remove any buildup, and tightening the clamp as necessary to maintain a secure connection. Adhering to these maintenance practices helps prevent issues and ensures the clamp continues to function effectively.

Compatibility and Applications

The 3690650 is designed for use in specific applications within commercial truck systems. Its compatibility with various types of tubing and systems makes it a versatile component for maintaining and upgrading truck infrastructure. When selecting or replacing tube clamps, it is important to consider the specific requirements of the application to ensure optimal performance and compatibility with other components.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its commitment to quality and performance in the commercial vehicle industry. The company’s reputation is built on its ability to deliver reliable and efficient solutions for a wide array of applications, from on-highway to off-highway and industrial uses.

Tube Clamp 3690650 Compatibility with Cummins Engines

The Tube Clamp part number 3690650, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems by securing tubes and hoses in place.

QSX15 Engine

For the QSX15 engine, the Tube Clamp 3690650 is engineered to fit perfectly with the engine’s design. It ensures that all coolant and exhaust tubes are securely fastened, preventing leaks and maintaining optimal engine performance.

CM2350 and X105 Engines

Similarly, the Tube Clamp 3690650 is compatible with both the CM2350 and X105 engines. These engines benefit from the clamp’s robust design, which provides a reliable seal for the tubes and hoses, contributing to the overall efficiency and longevity of the engine.

Grouped Engine Compatibility

When considering the QSX15, CM2350, and X105 engines together, it is evident that the Tube Clamp 3690650 is a versatile component. Its design allows it to be used across these models, ensuring that the engines operate smoothly and efficiently. This compatibility highlights the importance of using genuine Cummins parts for maintenance and repairs, ensuring that the engine’s performance is not compromised.

Role of Part 3690650 Tube Clamp in Engine Systems

The 3690650 Tube Clamp is instrumental in ensuring the secure and efficient operation of various engine systems. In the context of an Exhaust Recirculation (EGR) System, this tube clamp plays a significant role by maintaining the integrity of the EGR tube connections. It ensures that the recirculated exhaust gases are effectively channeled back into the intake manifold, thereby reducing nitrogen oxides (NOx) emissions and improving overall engine efficiency.

In an arrangement involving multiple hoses and tubes, the 3690650 Tube Clamp provides a reliable connection point. It prevents leaks and ensures that the fluid dynamics within the system remain consistent. This is particularly important in systems where precise control of fluid flow is necessary for optimal engine performance.

Furthermore, the tube clamp contributes to the durability and longevity of the engine systems it is a part of. By securing connections and preventing wear and tear on the tubes, it helps maintain the structural integrity of the entire system. This, in turn, leads to more stable engine operation and reduced maintenance requirements over time.

Conclusion

In summary, the 3690650 Tube Clamp is a vital component in maintaining the efficiency and reliability of engine systems, particularly in applications involving exhaust recirculation and complex hose arrangements. Its role in securing connections, preventing leaks, and ensuring consistent fluid dynamics is crucial for the optimal performance of commercial truck engines.

-

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.