This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

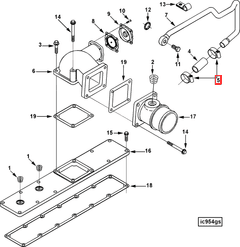

The Cummins 3863544 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, ensuring the secure connection of tubing. Understanding its purpose and significance is fundamental for maintaining the efficiency and reliability of commercial trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by providing a tight seal around the tubing, preventing leaks and ensuring the integrity of the system. Tube clamps come in different designs and materials, tailored to specific applications and environmental conditions 1.

Purpose of the Cummins 3863544 Tube Clamp

The Cummins 3863544 Tube Clamp plays a role in the operation of commercial trucks by securing tubing connections in various systems. Its application ensures that fluids and gases are transported efficiently without leakage, contributing to the overall performance and safety of the truck 2.

Key Features

This Cummins part is constructed with materials and a design that enhance its performance and durability. It features a robust clamping mechanism that ensures a secure fit around the tubing. The materials used are chosen for their resistance to corrosion and ability to withstand high pressures and temperatures, making the clamp suitable for demanding commercial truck applications 3.

Benefits

Using the 3863544 Tube Clamp offers several advantages. It provides improved reliability in tubing connections, reducing the risk of leaks. The design allows for ease of installation, minimizing downtime during maintenance. Additionally, its durability contributes to maintenance efficiency, as it requires less frequent replacement compared to other clamping solutions.

Installation Process

Installing this part involves several steps to ensure a secure fit. First, the tubing should be cleaned and prepared for clamping. The clamp is then positioned around the tubing and tightened using the appropriate tools. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which could damage the tubing or the clamp itself.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the clamp. Troubleshooting steps may involve re-tightening the clamp, inspecting the tubing for damage, or replacing the clamp if it shows signs of wear.

Maintenance Tips

Regular maintenance checks for the 3863544 Tube Clamp are recommended to ensure long-term performance. This includes inspecting the clamp for signs of corrosion, wear, or damage and ensuring that it remains securely tightened. Keeping the tubing and clamp clean can also prevent buildup that might affect performance.

Compatibility and Applications

The 3863544 Tube Clamp is designed for use in specific commercial truck systems. It is important to consider compatibility with other components to ensure optimal performance. Applications may vary depending on the truck’s make and model, and it is advisable to consult the manufacturer’s guidelines for specific compatibility information.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the automotive and industrial sectors. The company’s commitment to excellence is reflected in its products, including the 3863544 Tube Clamp.

Cummins Tube Clamp 3863544 Compatibility

The Tube Clamp 3863544, manufactured by Cummins, is a critical component designed to secure and maintain the integrity of various engine systems. This part is integral in ensuring that the engine operates efficiently and safely by preventing leaks and maintaining the structural integrity of the engine’s tubing.

Engine Compatibility

The Tube Clamp 3863544 is compatible with several Cummins engine models, including but not limited to:

- 6C8.3

This tube clamp is engineered to fit seamlessly into the engine’s design, providing a reliable seal and support for the tubing that carries essential fluids and gases. Its robust construction ensures that it can withstand the high pressures and temperatures typical of engine environments.

Application in Engines

In the 6C8.3 engine, the Tube Clamp 3863544 is used to secure various types of tubing, including fuel lines, coolant lines, and other critical pathways. Its design allows for easy installation and removal, making it a convenient choice for maintenance and repairs. The clamp’s ability to provide a tight seal is crucial for preventing leaks, which can lead to performance issues and potential engine damage.

Importance of Proper Fitment

Proper fitment of the Tube Clamp 3863544 is essential for the overall performance and longevity of the engine. Ensuring that the clamp is correctly installed and tightened to the manufacturer’s specifications is vital. This ensures that the tubing remains secure and that there are no gaps or weak points that could compromise the engine’s operation.

Maintenance and Replacement

Regular inspection of the Tube Clamp 3863544 is recommended to ensure it remains in good condition. Over time, the clamp may wear out or become damaged, necessitating replacement. Using genuine Cummins parts for replacement ensures that the engine continues to operate at peak efficiency and reliability.

By understanding the compatibility and application of the Tube Clamp 3863544, engine operators and maintenance personnel can ensure that their Cummins engines remain in optimal condition, providing reliable performance and minimizing downtime.

Role of Part 3863544 Tube Clamp in Engine Systems

The 3863544 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in maintaining the integrity of connections within these systems, facilitating smooth and reliable performance.

Breather System

In the breather system, the 3863544 Tube Clamp is utilized to secure the connections between the breather tubes and the crankcase. This ensures that the breather system can effectively vent pressure and contaminants from the crankcase, maintaining a clean and pressurized environment. The clamp’s reliable hold prevents leaks, which could otherwise lead to inefficient breather operation and potential engine damage.

Crankcase Ventilation

For crankcase ventilation, the Tube Clamp is employed to maintain a tight seal between the ventilation tubes and the crankcase. This is vital for the proper circulation of air within the crankcase, helping to remove moisture, sludge, and other byproducts of combustion. A secure connection ensured by the clamp prevents the escape of harmful gases and contaminants, contributing to the overall health and longevity of the engine.

Air Intake System

In the air intake system, the 3863544 Tube Clamp is used to connect the air intake tubes to the engine’s air filter housing or throttle body. This connection is essential for delivering a consistent and clean air supply to the engine, which is necessary for optimal combustion and performance. The clamp ensures that the air intake system remains sealed, preventing any unfiltered air from entering the engine and causing potential damage.

General Connection Integrity

Across all these systems, the primary role of the 3863544 Tube Clamp is to provide a robust and dependable connection. Its application in these critical areas underscores its importance in maintaining the efficiency and reliability of the engine. By securing these connections, the clamp helps to ensure that each system operates within its designed parameters, contributing to the engine’s overall performance and durability.

Conclusion

The Cummins 3863544 Tube Clamp is a vital component in the maintenance and operation of commercial trucks and engines. Its role in securing tubing connections ensures the efficient and safe transport of fluids and gases, contributing to the overall performance and reliability of the vehicle. Understanding its features, benefits, and proper installation and maintenance procedures is essential for maximizing its effectiveness and longevity.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.