This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Wire Tie Clamp part 3900109, manufactured by Cummins, is a component designed to secure and organize wires and cables in commercial trucks. Its role is significant in maintaining the integrity and functionality of the vehicle’s electrical systems. Cummins, a well-established name in the industry, ensures that this clamp meets the rigorous demands of commercial truck operations.

Basic Concepts of Wire Tie Clamps

Wire tie clamps are devices used to bundle and secure wires and cables, preventing them from tangling or coming loose. They function by compressing the wires together, which helps in managing cable runs and reducing the risk of electrical interference. These clamps find applications in various automotive and industrial settings, where organized wiring is crucial for safety and efficiency. Commonly, wire tie clamps are constructed from materials like nylon, metal, or specialized polymers, chosen for their durability and resistance to environmental factors 1.

Purpose of the 3900109 Wire Tie Clamp in Truck Operation

In the context of commercial trucks, the 3900109 Wire Tie Clamp plays a specific role in securing wires and cables, which is vital for the proper functioning of the vehicle’s electrical systems. By keeping wires organized and protected, it contributes to the overall efficiency and safety of the truck. This is particularly important in heavy-duty applications where vibrations and harsh conditions can lead to wire damage if not properly secured 2.

Key Features of the 3900109 Wire Tie Clamp

The 3900109 Wire Tie Clamp is characterized by several key features. Its design includes a robust construction that can withstand the rigors of commercial truck environments. The clamp is made from high-quality materials, ensuring durability and long-term performance. Unique characteristics may include a self-locking mechanism for easy installation and adjustment, as well as resistance to chemicals and extreme temperatures commonly encountered in truck operations.

Benefits of Using the 3900109 Wire Tie Clamp

Utilizing the 3900109 Wire Tie Clamp offers several advantages. Its durable construction ensures longevity, reducing the need for frequent replacements. The ease of installation is another benefit, allowing for quick and efficient wire management during both initial setup and maintenance procedures. Additionally, its reliability in various operating conditions makes it a valuable component for ensuring the electrical systems of commercial trucks remain secure and functional 3.

Installation Process

Installing the 3900109 Wire Tie Clamp involves a few straightforward steps. First, gather the wires or cables that need to be secured. Then, place the clamp around the bundle, ensuring it is positioned correctly. Using the appropriate tool, tighten the clamp until the wires are held securely in place. It is important to follow best practices, such as not over-tightening, to avoid damaging the wires or the clamp itself.

Troubleshooting Common Issues

Common issues with wire tie clamps may include loosening over time or damage from environmental factors. To troubleshoot, inspect the clamp for signs of wear or failure, such as cracks or excessive loosening. If any issues are detected, the clamp should be replaced to ensure the integrity of the wire bundle is maintained.

Maintenance Tips

Regular maintenance of the 3900109 Wire Tie Clamp is important for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage. Replacement guidelines should be followed if the clamp shows any signs of failure. Additionally, keeping the area around the clamp clean and free from debris can help prevent premature wear.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components. With a history of innovation and commitment to quality, Cummins has established a strong reputation for producing reliable and durable truck parts. The company’s dedication to excellence is evident in its product offerings, including the 3900109 Wire Tie Clamp, which is designed to meet the demanding requirements of commercial truck operations.

Role of Part 3900109 Wire Tie Clamp in Engine Systems

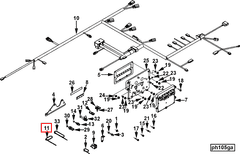

The 3900109 Wire Tie Clamp is an essential component in the assembly and maintenance of various engine systems, ensuring the secure and organized routing of wiring harnesses and electrical connections. Its application spans across several key components, enhancing both the functionality and reliability of the engine system.

Electronic Control Module Wiring Harness

In the Electronic Control Module (ECM) Wiring Harness, the 3900109 Wire Tie Clamp is utilized to bundle and secure wires that connect the ECM to various sensors and actuators throughout the engine. This organization prevents wire tangling and reduces the risk of electrical shorts, ensuring consistent signal transmission and reliable engine performance.

HHP 12V VLV/ELEC and HHP 24V VLV/ELEC Kits

For the HHP 12V VLV/ELEC and HHP 24V VLV/ELEC Kits, the Wire Tie Clamp plays a significant role in managing the electrical connections associated with the valve and electronic components. By securing wires in place, it aids in maintaining the integrity of the electrical pathways, which is vital for the precise operation of the valve systems and overall engine efficiency.

Engine Control Module

In the Engine Control Module (ECM), the 3900109 Wire Tie Clamp is employed to organize the myriad of wires that interface with the ECM. This organization is key to preventing interference and ensuring that the ECM receives accurate data from all connected components, which is essential for optimal engine management.

N14 12V Pressure-Time Centinel Kit and N14 24V Hardware-Pressure-Time Valve/Mounting Kit

Within the N14 12V Pressure-Time Centinel Kit and the N14 24V Hardware-Pressure-Time Valve/Mounting Kit, the Wire Tie Clamp is used to secure the wiring that monitors and controls the pressure-time functions. This ensures that the pressure sensors and valves operate within specified parameters, contributing to the engine’s performance and longevity.

Oil Replenishing System

In the Oil Replenishing System, the 3900109 Wire Tie Clamp helps in organizing the wiring that controls the oil level sensors and replenishment mechanisms. Proper wire management is essential to ensure that the system accurately detects oil levels and replenishes oil as needed, maintaining engine lubrication and preventing damage.

Conclusion

Overall, the 3900109 Wire Tie Clamp is a fundamental component in the intricate web of engine systems, providing the necessary organization and security for wiring harnesses and electrical connections. Its application across various engine components underscores its importance in maintaining the reliability and performance of modern engine systems.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.