This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

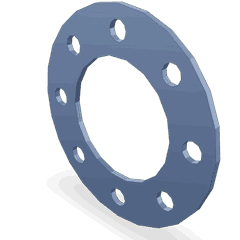

The Cummins 3908337 Clamping Ring is a critical component designed to secure various parts within the mechanical systems of commercial trucks. Its role is significant in ensuring the proper operation and longevity of truck engines and related systems.

Basic Concepts of Clamping Rings

Clamping rings are mechanical components used to hold parts in place within a system. They function by applying pressure to secure components, preventing movement and ensuring stability. This is essential for maintaining the integrity and efficiency of mechanical operations 1.

Purpose of the 3908337 Clamping Ring

The 3908337 Clamping Ring is specifically designed to secure components within a truck’s engine or other systems. Its application ensures that parts remain fixed, which is vital for the consistent performance and reliability of the truck’s mechanical functions.

Key Features

The design and material characteristics of the 3908337 Clamping Ring contribute to its effectiveness and durability. Crafted from high-quality materials, it is engineered to withstand the rigors of commercial truck operations, providing a secure fit and long-lasting performance 2.

Benefits

Utilizing the 3908337 Clamping Ring offers several advantages, including improved reliability of the truck’s mechanical systems, enhanced performance through secure component fixation, and increased longevity of associated parts due to its durable construction.

Installation Process

Proper installation of the 3908337 Clamping Ring involves a series of steps to ensure it is correctly positioned and secured. This process may require specific tools and adherence to manufacturer guidelines to achieve the desired outcome.

Common Issues and Troubleshooting

Typical problems that may arise with the 3908337 Clamping Ring include improper installation, wear and tear, or damage. Troubleshooting these issues involves inspecting the ring for signs of damage, ensuring it is correctly installed, and replacing it if necessary to maintain system integrity.

Maintenance Tips

Regular maintenance of the 3908337 Clamping Ring is recommended to ensure optimal performance and longevity. This includes periodic inspection for wear, ensuring it remains securely in place, and replacing it according to manufacturer guidelines or when signs of degradation are observed.

Cummins Corporation Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history and commitment to innovation have established it as a trusted name in the field of diesel engines and related technologies.

Cummins Engine Compatibility with Part 3908337

The Cummins Clamping Ring part number 3908337 is designed to ensure proper sealing and performance in various Cummins engine models. This part is integral to maintaining the integrity of the engine’s systems, particularly in applications where high pressure and tight tolerances are required.

ISB Series Engines

The ISB series engines, which include:

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

benefit from the use of the 3908337 Clamping Ring. This part is essential in these engines for maintaining the seal between various components, ensuring that there are no leaks and that the engine operates efficiently.

ISC Series Engines

The ISC series engines, specifically:

- ISC CM554

- ISC CM850

also utilize the 3908337 Clamping Ring. In these engines, the clamping ring plays a crucial role in securing the connections between different parts, which is vital for the overall performance and longevity of the engine.

ISL Series Engines

The ISL series engines, including:

- ISL CM554

- ISL9 CM2150 SN

are designed to work seamlessly with the 3908337 Clamping Ring. This part ensures that the connections within these engines are tight and secure, which is essential for maintaining the high standards of performance expected from ISL engines.

QSB Series Engines

The QSB series engines, which encompass:

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

are another set of engines that rely on the 3908337 Clamping Ring. This part is crucial in these engines for ensuring that all connections are properly sealed and that the engine operates at peak efficiency.

B Series Engines

The B series engines, including:

- 4B3.9

- 6B5.9

- 6C8.3

- B5.9 G

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

- C8.3 G

- QSC8.3 CM554

also utilize the 3908337 Clamping Ring. This part is essential in these engines for maintaining the seal between various components, ensuring that the engine operates efficiently and reliably.

Each of these engines, despite their differences, shares a common requirement for the 3908337 Clamping Ring to ensure optimal performance and longevity. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Role of Part 3908337 Clamping Ring in Engine Systems

The 3908337 Clamping Ring is an essential component in the assembly and operation of several engine systems, particularly those involving the Flexplate and Flywheel.

In systems utilizing a Flexplate, the Clamping Ring secures the Flexplate to the crankshaft, ensuring a stable connection that is vital for the transmission of power from the engine to the transmission. This secure fit prevents any slippage or misalignment that could lead to inefficient power transfer or damage to the Flexplate.

Similarly, in systems with a Flywheel, the Clamping Ring plays a significant role. It ensures that the Flywheel is firmly attached to the crankshaft. This is important for the smooth operation of the engine, as the Flywheel helps in storing rotational energy and smoothing out the power delivery to the transmission. A well-secured Flywheel, thanks to the Clamping Ring, contributes to the overall stability and efficiency of the engine’s power transmission.

Furthermore, the Clamping Ring is integral in the Mounting process of both the Flexplate and Flywheel. It provides the necessary pressure to keep these components in place, which is essential for the proper functioning of the engine. Without a reliable Clamping Ring, the mounting of these components would be insecure, leading to potential engine performance issues or even failure.

In summary, the 3908337 Clamping Ring is a key element in ensuring the secure and efficient operation of the Flexplate and Flywheel within engine systems. Its role in maintaining the integrity of these components’ mounting is fundamental to the overall performance and reliability of the engine.

Conclusion

The Cummins 3908337 Clamping Ring is a vital component in the maintenance and operation of commercial truck engines. Its role in securing components, ensuring system integrity, and contributing to the overall performance and reliability of the engine cannot be overstated. Proper installation, maintenance, and understanding of its application across various Cummins engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.