This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

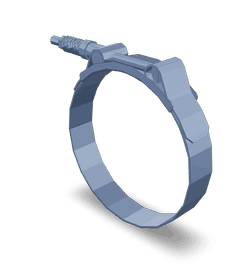

The T-Bolt Clamp 3911732, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty vehicles. This Cummins part is integral to the secure operation of various truck systems.

Basic Concepts of T-Bolt Clamps

T-Bolt Clamps are mechanical fasteners used to secure components in various systems. They consist of a U-shaped channel with a threaded bolt that passes through the channel and into a T-shaped slot. When tightened, the bolt expands the channel, creating a firm grip on the components it surrounds. This mechanism is commonly employed in applications requiring a secure yet adjustable connection 1.

Purpose of the 3911732 T-Bolt Clamp in Truck Operations

In commercial truck operations, the 3911732 T-Bolt Clamp serves to secure components within the truck’s systems, ensuring they remain in place under various operating conditions. Its role is particularly significant in applications where vibrations or movements could otherwise loosen traditional fasteners, potentially leading to component failure or system malfunction 2.

Key Features of the 3911732 T-Bolt Clamp

The 3911732 T-Bolt Clamp is characterized by several key features that enhance its functionality and reliability. It is constructed from durable materials, ensuring resistance to wear and corrosion. The design includes a U-shaped channel and a T-shaped slot, allowing for easy installation and adjustment. Additionally, the clamp’s unique characteristics, such as its ability to distribute clamping force evenly, contribute to its effectiveness in securing components.

Benefits of Using the 3911732 T-Bolt Clamp

Utilizing the 3911732 T-Bolt Clamp offers several advantages. Its durable construction ensures longevity, while its design facilitates ease of installation. The clamp’s reliability in securing components under various conditions contributes to the overall performance and safety of the truck. Furthermore, its adjustable nature allows for precise fitting, accommodating different component sizes and shapes 3.

Installation Process

Installing the 3911732 T-Bolt Clamp involves several steps to ensure proper fitting and functionality. Begin by positioning the U-shaped channel around the components to be secured. Insert the threaded bolt through the channel and into the T-shaped slot. Using the appropriate tools, tighten the bolt to achieve the desired clamping force. It is important to follow best practices, such as ensuring the components are aligned correctly and the clamp is tightened evenly, to maximize the clamp’s effectiveness.

Maintenance and Care

Regular maintenance and care of the 3911732 T-Bolt Clamp are crucial for ensuring its longevity and optimal performance. Inspect the clamp periodically for signs of wear or corrosion, and clean it as necessary to remove any debris that could affect its functionality. Tightening the clamp as needed will help maintain a secure fit on the components it surrounds.

Troubleshooting Common Issues

Common issues with the 3911732 T-Bolt Clamp may include loosening over time or difficulty in achieving a secure fit. To address these problems, ensure the clamp is tightened correctly and check for any damage to the components or the clamp itself. In cases where the clamp no longer provides a secure fit, it may be necessary to replace it to maintain system integrity.

Compatibility and Applications

The 3911732 T-Bolt Clamp is designed for use in various commercial truck systems, where secure component fastening is required. Its compatibility with different components and systems makes it a versatile choice for truck maintenance and repair. When selecting a T-Bolt Clamp for a specific application, consider the size and shape of the components to be secured, as well as the operating conditions the clamp will face.

About Cummins

Cummins is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality parts and systems. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and durable components that enhance the performance and efficiency of commercial trucks. Their product range includes engines, transmissions, and various aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

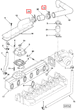

T-Bolt Clamp Part 3911732 Compatibility with Cummins Engines

The T-Bolt Clamp part number 3911732, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part is integral in securing various components within the engine assembly, ensuring stability and proper function.

6B5.9 Engine

The 6B5.9 engine benefits from the T-Bolt Clamp part 3911732, which is used to secure certain parts of the engine’s internal structure. This clamp is crucial in maintaining the alignment and integrity of the engine’s components, contributing to the overall performance and longevity of the engine.

6C8.3 Engine

Similarly, the 6C8.3 engine utilizes the T-Bolt Clamp part 3911732 to ensure that specific parts remain firmly in place. This clamp plays a vital role in the engine’s assembly, providing the necessary support and stability to various components, thereby enhancing the engine’s operational efficiency and reliability.

Grouping of Engines

Both the 6B5.9 and 6C8.3 engines are part of Cummins’ lineup of robust and reliable diesel engines. The T-Bolt Clamp part 3911732 is compatible with these engines, indicating its versatility and importance in maintaining the structural integrity of these engines. This compatibility underscores the part’s significance in the engine’s assembly process, ensuring that the engine operates smoothly and efficiently.

Role of Part 3911732 T-Bolt Clamp in Engine Systems

The T-Bolt Clamp, identified by part number 3911732, is instrumental in securing various components within engine systems, ensuring stability and efficiency. Its application is particularly significant in the arrangement and maintenance of the turbocharger and its associated systems.

In the context of turbocharger arrangements, the T-Bolt Clamp is utilized to fasten the turbocharger to its mounting brackets. This secure attachment is essential for maintaining the turbocharger’s position and alignment, which directly influences its performance and durability. The clamp ensures that the turbocharger remains firmly in place, even under the high stresses and vibrations inherent in engine operation.

Furthermore, the T-Bolt Clamp plays a role in the turbocharger location setup. Proper placement of the turbocharger is vital for optimal airflow and efficiency. The clamp helps in achieving precise turbocharger positioning, which is critical for the effective functioning of the entire exhaust and intake system. It allows for adjustments and fine-tuning of the turbocharger’s location, ensuring that it operates within the desired parameters for peak performance.

Additionally, the T-Bolt Clamp is employed in securing various hoses, pipes, and other components connected to the turbocharger. This includes the intercooler pipes, exhaust manifold connections, and intake system components. By providing a reliable and robust connection, the clamp contributes to the overall integrity and performance of the engine system.

Conclusion

In summary, the T-Bolt Clamp (part 3911732) is a key component in the secure and efficient arrangement of turbochargers and related systems, playing a significant role in maintaining the performance and reliability of engine systems.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.