This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

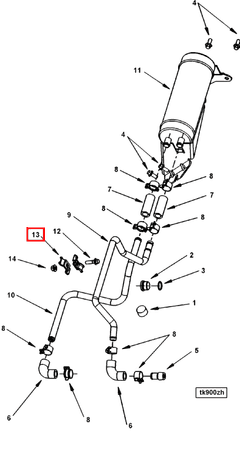

The 3912089 Tube Clamp, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to maintaining the integrity and efficiency of fluid systems in heavy-duty vehicles. Tube clamps like the 3912089 are vital for ensuring secure connections in fluid transfer systems, which are essential for the operation of various vehicle systems 1.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure tubing in fluid systems, ensuring a tight and reliable connection. They are commonly employed in applications involving fuel, coolant, and hydraulic lines. Tube clamps come in various types, including worm-drive, screw-type, and band-style clamps, each offering different levels of adjustability and ease of use 2. The primary function of a tube clamp is to create a secure seal that prevents leaks and maintains system pressure. Secure connections are fundamental in fluid transfer systems to ensure efficient operation and prevent system failures 3.

Purpose of the 3912089 Tube Clamp in Truck Operations

The 3912089 Tube Clamp plays a specific role in the operation of commercial trucks by securing tubing in fluid systems such as fuel, coolant, and hydraulic lines. Its function contributes to the efficiency and reliability of these systems by ensuring that connections remain tight and leak-free. This is particularly important in heavy-duty trucks, where fluid systems operate under high pressure and stress 4.

Key Features of the 3912089 Tube Clamp

The 3912089 Tube Clamp is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear. The clamping mechanism allows for easy adjustment, ensuring a secure fit on various tube sizes. Additionally, the clamp’s design includes features that facilitate ease of installation and maintenance-free operation 5.

Benefits of Using the 3912089 Tube Clamp

The 3912089 Tube Clamp offers several advantages for use in commercial trucks. Its ease of installation makes it a convenient choice for both original equipment manufacturers and maintenance technicians. The clamp is maintenance-free, reducing the need for regular checks and adjustments. It also provides resistance to corrosion, ensuring longevity in harsh operating environments. Furthermore, the clamp is compatible with a wide range of tube materials and sizes, making it versatile for various applications 6.

Installation and Usage Guidelines

Proper installation of the 3912089 Tube Clamp involves selecting the appropriate clamp size for the tubing being used and ensuring a secure fit. Step-by-step instructions should be followed to achieve the best results. Tips for usage include verifying the clamp’s compatibility with the specific fluid system and ensuring that all connections are tight and leak-free. Regular checks should be performed to confirm the clamp remains secure over time 7.

Troubleshooting and Maintenance

Common issues with tube clamps include leaks and clamp failure. Identifying these problems early can prevent more significant system failures. Troubleshooting steps involve checking for signs of wear or corrosion on the clamp and ensuring that the tubing is not damaged. Maintenance tips include periodic inspection of the clamp and tubing for any signs of wear or damage and replacing the clamp if necessary to ensure continued system integrity 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and engine industry, known for its commitment to quality and innovation. The company offers a wide range of products designed for commercial vehicles, emphasizing reliability and performance. Cummins’ role in providing components like the 3912089 Tube Clamp underscores its dedication to supporting the efficiency and safety of commercial truck operations 9.

Tube Clamp 3912089 Compatibility with Cummins Engines

The Tube Clamp part number 3912089, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This part is crucial for securing and maintaining the integrity of the engine’s tubing systems.

6B5.9 and B5.9 G Engines

For the 6B5.9 and B5.9 G engines, the Tube Clamp 3912089 is engineered to provide a reliable connection for various tubing applications. These engines, known for their robust performance, benefit from the clamp’s precision fit and durability, ensuring that the tubing remains securely fastened under all operating conditions.

ISB CM550 and ISB CM850 Engines

Similarly, the ISB CM550 and ISB CM850 engines also utilize the Tube Clamp 3912089. These engines, which are part of Cummins’ Industrial Series, are designed for heavy-duty applications. The clamp’s compatibility with these engines ensures that the tubing systems are effectively secured, contributing to the overall reliability and performance of the engine.

The Tube Clamp 3912089 is a critical component in maintaining the integrity of the engine’s tubing systems across these various engine models. Its design and material ensure that it can withstand the demands of these engines, providing a secure and lasting connection.

Role of Part 3912089 Tube Clamp in Engine Systems

The 3912089 Tube Clamp is instrumental in securing and maintaining the integrity of various fluid pathways within engine systems. In block vent plumbing, it ensures that the vent lines remain firmly attached, preventing any potential leaks that could affect engine performance or lead to unsafe conditions.

When integrated with the cooler system, particularly the torque converter oil cooler and the torque converter cooler, the tube clamp plays a significant role in maintaining consistent fluid flow. This is essential for efficient heat exchange, which in turn helps in maintaining optimal operating temperatures for the torque converter.

In the context of general plumbing within the engine, the 3912089 Tube Clamp is used to secure connections between various components, ensuring that fluid pathways remain intact under varying pressure conditions. This is particularly important in systems where precise fluid management is required, such as in the exhaust recirculation water system, where it helps in maintaining the correct water flow for effective exhaust gas recirculation.

Additionally, in engine coolant systems, the tube clamp is employed to secure coolant lines, ensuring that the coolant circulates efficiently through the engine block and other components. This is vital for dissipating heat and protecting engine parts from overheating.

Overall, the 3912089 Tube Clamp is a fundamental component in ensuring the reliability and efficiency of fluid systems within engine applications.

Conclusion

The 3912089 Tube Clamp by Cummins is a vital component in the maintenance and operation of fluid systems in commercial trucks and engines. Its design, durability, and ease of use make it an essential part for ensuring secure and leak-free connections in various fluid transfer systems. The clamp’s compatibility with a wide range of Cummins engines further underscores its importance in maintaining the efficiency and reliability of these systems.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Bosch, R. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Bosch, R. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.