This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The U Bolt Clamp 3917826 is a component manufactured by Cummins, a well-established name in the commercial vehicle industry. This clamp is integral to various applications within commercial truck operations, providing a reliable fastening solution that ensures the secure attachment of components.

Basic Concepts of U Bolt Clamps

U Bolt Clamps are mechanical fasteners designed to hold two surfaces together. They consist of a U-shaped bolt with threaded ends that pass through holes in the surfaces being joined. Nuts are then tightened onto these threads to draw the surfaces together, creating a secure connection. These clamps are commonly used in applications requiring strong, durable fastening solutions 1.

Purpose of U Bolt Clamp 3917826 in Truck Operations

The U Bolt Clamp 3917826 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various applications, including securing exhaust systems, attaching brackets, and fastening other critical components. Its function is to provide a robust and reliable connection that can withstand the rigors of heavy-duty truck operations 2.

Key Features

The U Bolt Clamp 3917826 is characterized by several primary features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise threading and a robust U-shape, which contributes to its strength and reliability. Additionally, the clamp may feature unique attributes such as a protective coating or specialized threading to further improve its functionality 3.

Benefits of Using U Bolt Clamp 3917826

Utilizing the U Bolt Clamp 3917826 offers several advantages. It provides improved safety by ensuring that components remain securely fastened, reducing the risk of detachment during operation. The clamp also enhances reliability, as its durable construction can withstand the demanding conditions of commercial truck use. Furthermore, it contributes to efficiency in truck maintenance by offering a straightforward and effective fastening solution 4.

Installation Process

Installing the U Bolt Clamp 3917826 involves several steps to ensure a proper and secure connection. Begin by aligning the U-shaped bolt with the holes in the surfaces to be joined. Insert the bolt and tighten the nuts on each end gradually to draw the surfaces together. It is important to tighten the nuts evenly to avoid misalignment and ensure a strong connection. Best practices include using a torque wrench to achieve the recommended tightening specifications and inspecting the connection for any signs of instability 2.

Troubleshooting Common Issues

Frequent problems with U Bolt Clamps may include loosening over time, corrosion, or damage to the clamp or surfaces. To address these issues, regularly inspect the clamp for signs of wear or corrosion. If loosening is detected, re-tighten the nuts to the specified torque. In cases of corrosion, cleaning the affected areas and applying a protective coating can help prevent further degradation. For damaged clamps, replacement may be necessary to maintain a secure connection 2.

Maintenance Tips

To ensure the longevity and optimal performance of the U Bolt Clamp 3917826, regular maintenance is recommended. This includes periodic inspection of the clamp and connected surfaces for signs of wear, corrosion, or damage. Cleaning the clamp and applying a protective coating can help prevent corrosion. Additionally, ensuring that the nuts are tightened to the correct torque specifications during installation and re-inspections will help maintain a secure connection 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial vehicle industry. The company’s extensive product range includes engines, powertrains, and components designed to meet the demanding requirements of heavy-duty applications. The U Bolt Clamp 3917826 is a testament to Cummins’ commitment to providing durable and reliable solutions for commercial truck operations 3.

Cummins U Bolt Clamp 3917826 in Engine Applications

The Cummins U Bolt Clamp 3917826 is a critical component in securing various parts within the engine assembly. This part is designed to provide a reliable fastening solution, ensuring that components remain securely in place during engine operation.

Application in Specific Engines

4B3.9 Engine Series

The U Bolt Clamp 3917826 is integral to the 4B3.9 engine series. It is used in securing various engine components, ensuring that parts such as exhaust manifolds, fuel lines, and other critical elements are fastened securely. The clamp’s robust design and high-strength material make it suitable for withstanding the operational stresses within the engine environment 3.

Other Cummins Engines

While the primary focus here is on the 4B3.9 engine, the U Bolt Clamp 3917826 is also applicable in other Cummins engine models. Its versatility allows it to be used in a variety of engine configurations, providing a consistent and reliable fastening solution across different engine types 3.

The clamp’s design ensures that it can be easily installed and removed, facilitating maintenance and repair processes. Its compatibility with various engine parts makes it a valuable component in the engine assembly, contributing to the overall integrity and performance of the engine 3.

Role of Part 3917826 U Bolt Clamp in Engine Systems

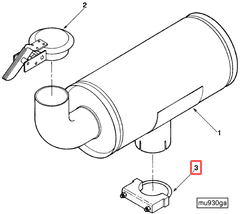

The U Bolt Clamp, identified by part number 3917826, is a critical component in the assembly and securement of various engine system components. Its primary function is to provide a robust and reliable connection between the muffler and the exhaust system.

Integration with the Muffler

In engine systems, the muffler plays a significant role in reducing noise levels produced by the engine. The U Bolt Clamp ensures that the muffler is firmly attached to the exhaust pipe, preventing any potential detachment or misalignment that could lead to increased noise or even exhaust leaks.

The design of the U Bolt Clamp allows for easy installation and removal, which is particularly beneficial during maintenance or replacement of the muffler. Its ability to withstand high temperatures and vibrations makes it an ideal choice for securing the muffler in place, ensuring both safety and efficiency in the engine’s operation 4.

Ensuring Structural Integrity

Beyond its role in securing the muffler, the U Bolt Clamp contributes to the overall structural integrity of the exhaust system. By providing a strong and durable connection, it helps maintain the alignment of the exhaust components, which is vital for optimal engine performance.

Proper alignment ensures that exhaust gases flow smoothly through the system, reducing backpressure and enhancing engine efficiency. Additionally, a well-secured muffler minimizes the risk of exhaust gases escaping, which could pose safety hazards and affect the engine’s performance 4.

Facilitating Maintenance and Repairs

The U Bolt Clamp’s design also facilitates easier maintenance and repairs. When a muffler needs to be replaced or serviced, the U Bolt Clamp allows for quick disconnection and reconnection without requiring complex tools or procedures. This feature is particularly advantageous in professional settings where time efficiency is paramount.

Moreover, the clamp’s durability ensures that it can withstand repeated installations and removals, maintaining its effectiveness over the long term. This reliability is essential for both routine maintenance and unexpected repairs, ensuring that the engine system remains functional and safe 4.

Conclusion

The U Bolt Clamp 3917826 by Cummins is a vital component in the securement and efficiency of engine systems, particularly in relation to the muffler and exhaust components. Its design and functionality contribute to the overall performance and safety of the engine, making it a critical part in any engine system assembly.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ ↩ ↩ ↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ ↩ ↩ ↩ ↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.