This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3923049 Clamping Ring is a component designed for use in commercial trucks. It serves a specific function within the truck’s engine or transmission system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the performance of commercial trucks.

Basic Concepts of Clamping Rings

A clamping ring is a mechanical component used to secure two or more parts together, ensuring a tight seal or fit. In various mechanical systems, clamping rings play a role in maintaining the integrity of connections, preventing leaks, and ensuring that components remain in the correct position under operational conditions. They are commonly found in engine and transmission systems, where precise fits and seals are necessary for optimal performance 1.

Purpose of the 3923049 Clamping Ring

This Cummins part is specifically designed to function within the engine or transmission system of a truck. Its role involves securing components in place, ensuring a tight seal to prevent fluid leaks, and maintaining the structural integrity of the assembly. By doing so, it contributes to the efficient operation of the truck’s engine or transmission, enhancing overall performance and reliability.

Key Features

The 3923049 Clamping Ring is characterized by several key features that enhance its performance. It is made from durable materials, ensuring longevity and resistance to wear. Its design includes precise dimensions and tolerances to ensure a perfect fit within the engine or transmission system. Additionally, it may feature unique characteristics such as anti-rotation tabs or specialized coatings to improve sealing and durability.

Benefits

The advantages provided by the 3923049 Clamping Ring include improved sealing, which prevents leaks and maintains system pressure. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Furthermore, by ensuring a secure fit of components, it contributes to the efficient operation of the truck, enhancing overall performance.

Installation Process

Proper installation of the 3923049 Clamping Ring is crucial for its effective operation. The process involves cleaning the mating surfaces to ensure a proper seal, positioning the ring correctly within the assembly, and using the appropriate tools to secure it in place without damage. Following manufacturer guidelines for torque specifications and installation procedures is important to ensure correct fitting 2.

Common Issues and Troubleshooting

Common problems associated with the 3923049 Clamping Ring may include leaks due to improper installation or wear over time. Troubleshooting these issues involves inspecting the ring for signs of damage or wear, ensuring it is correctly positioned, and replacing it if necessary. Regular maintenance and inspection can help identify potential issues before they lead to significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3923049 Clamping Ring, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the mating surfaces to prevent contamination, and replacing the ring as part of routine maintenance schedules. Adhering to these practices can help maintain the efficiency and reliability of the truck’s engine or transmission system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial vehicle operators worldwide.

Cummins Engine Compatibility with Part 3923049

The 3923049 Clamping Ring is designed to fit a variety of Cummins engines. This part is integral in ensuring the proper sealing and functionality of the engine’s components. Below is a detailed breakdown of the engines with which this part is compatible:

Cummins B Series Engines

- B4.5

- B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

Cummins C Series Engines

- C GAS PLUS CM556

- C8.3 G

Cummins ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

Cummins ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

Cummins ISC Series Engines

- ISC CM554

- ISC CM850

Cummins ISF Series Engines

- ISF3.8 CM2220 AN

This Clamping Ring is essential for maintaining the integrity of the engine’s sealing and operational efficiency. Its compatibility across a wide range of Cummins engines underscores its versatility and importance in the engine’s assembly and maintenance.

Role of Part 3923049 Clamping Ring in Engine Systems

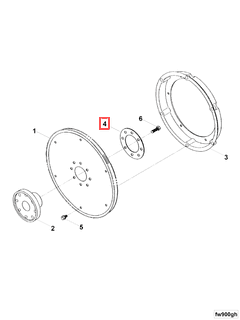

The 3923049 Clamping Ring is a component in the assembly and operation of various engine systems, particularly those involving the Flexplate and Flywheel.

Flexplate Integration

When integrating the Flexplate, the 3923049 Clamping Ring ensures a secure connection between the Flexplate and the Torque Converter. This connection is vital for the transmission of power from the engine to the transmission system. The Clamping Ring’s design allows it to withstand the high torque and rotational forces generated during engine operation, maintaining a stable and reliable connection.

Flexplate Service Kit

In a Flexplate Service Kit, the 3923049 Clamping Ring plays a significant role in the reassembly process. It ensures that all components are correctly aligned and securely fastened, which is essential for the Flexplate’s durability and performance. The Clamping Ring helps in maintaining the proper spacing and alignment, which is critical for the smooth operation of the engine.

Flywheel Assembly

For the Flywheel, the 3923049 Clamping Ring is used to secure the Flywheel to the crankshaft. This connection is fundamental for the efficient transfer of power from the engine to the transmission. The Clamping Ring’s robust construction ensures that it can handle the high stresses and vibrations associated with the Flywheel’s operation, providing a dependable and long-lasting connection.

Mounting Applications

In various mounting applications, the 3923049 Clamping Ring is employed to secure components to the engine block or other structural elements. Its role in these applications is to provide a strong and stable connection, ensuring that the mounted components remain in place under the dynamic conditions of engine operation. This is particularly important in high-performance engines where precision and reliability are paramount.

Overall Functionality

Across these applications, the 3923049 Clamping Ring contributes to the overall functionality and reliability of the engine system. By ensuring secure and precise connections, it helps in maintaining the integrity of the engine’s power transmission components, leading to enhanced performance and durability.

Conclusion

The Cummins 3923049 Clamping Ring is a vital component in the maintenance and operation of commercial truck engines. Its role in securing components, preventing leaks, and ensuring the structural integrity of engine assemblies is crucial for the efficient and reliable performance of these vehicles. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engines are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.